Alloy steel welding seam grinding and polishing equipment for high-end equipment manufacturing

A technology for alloy steel and equipment, which is applied in the field of grinding and polishing equipment for alloy steel welding seams used in high-end equipment manufacturing, and can solve the problems of low work efficiency, cumbersome work, and different effects of grinding and polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Such as figure 1 As shown, a grinding and polishing equipment for alloy steel welding seams for high-end equipment manufacturing includes a base 1, a slide rail 2, a workbench 3, a first bracket 4, a first servo motor 501, a rotating member 502, and a polishing wheel 6 , a fixing mechanism 7 and a driving mechanism 8, the base 1 is provided with the slide rail 2, the slide rail 2 is provided with the workbench 3 slidingly, and the middle part of the slide rail 2 is provided with the first The support 4, the first support 4 is provided with the first servo motor 501, the output shaft of the first servo motor 501 is provided with the rotating member 502, and the bottom of the rotating member 502 is provided with the polished wheel 6, the fixing mechanism 7 is arranged on the workbench 3, and the driving mechanism 8 is arranged on the right side of the base 1.

[0030] When it is necessary to polish the alloy steel weld seam welded on the steel plate of high-end equipment...

Embodiment 2

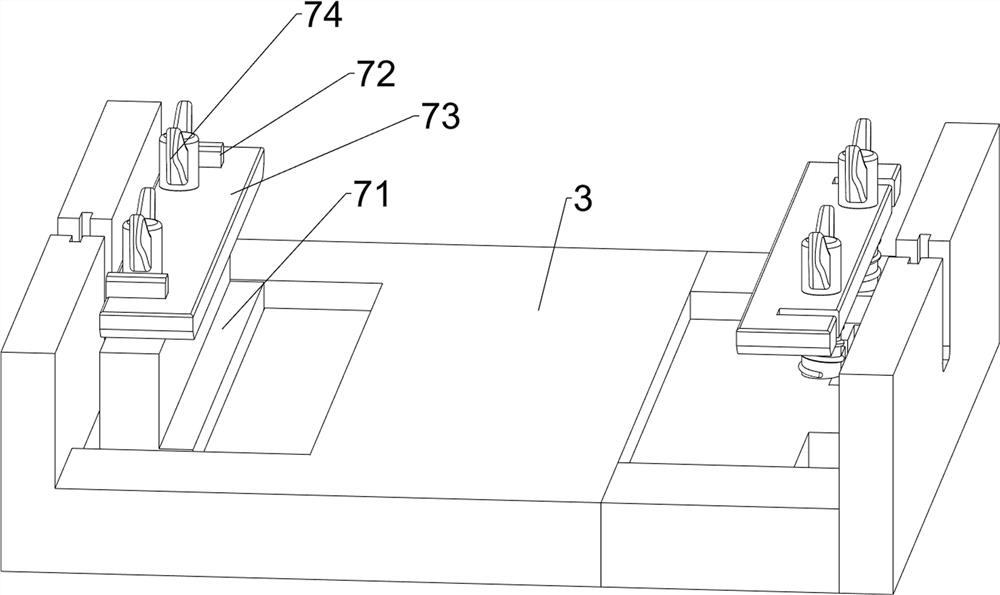

[0032] Such as figure 2 and image 3 As shown, on the basis of Embodiment 1, the fixing mechanism 7 includes a first fixing frame 71, a limit block 72, a pressing plate 73 and a tightening screw 74, and the front and rear sides of the workbench 3 are provided with the described The first fixed frame 71, the tops of the two first fixed frames 71 are left and right symmetrically provided with two said limiting blocks 72, and the two said limiting blocks 72 on the same side are all slidably provided with said The pressing plate 73 and the two first fixing frames 71 are provided with two tightening screws 74 symmetrically rotated left and right, and the two similar tightening screws 74 are slidingly connected with the pressing plate 73 .

[0033]When it is necessary to polish the alloy steel weld seam welded by the steel plate of the high-end equipment, the staff places the steel plate of the high-end equipment on the workbench 3, and then the staff rotates the tightening screw ...

Embodiment 3

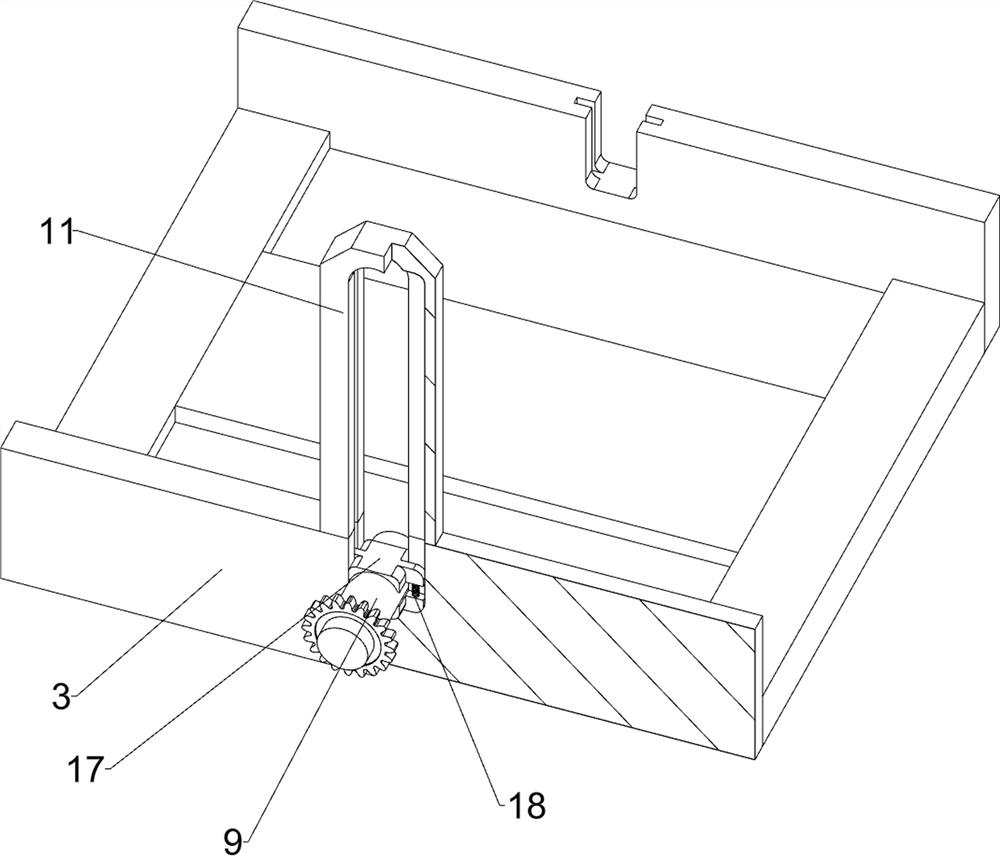

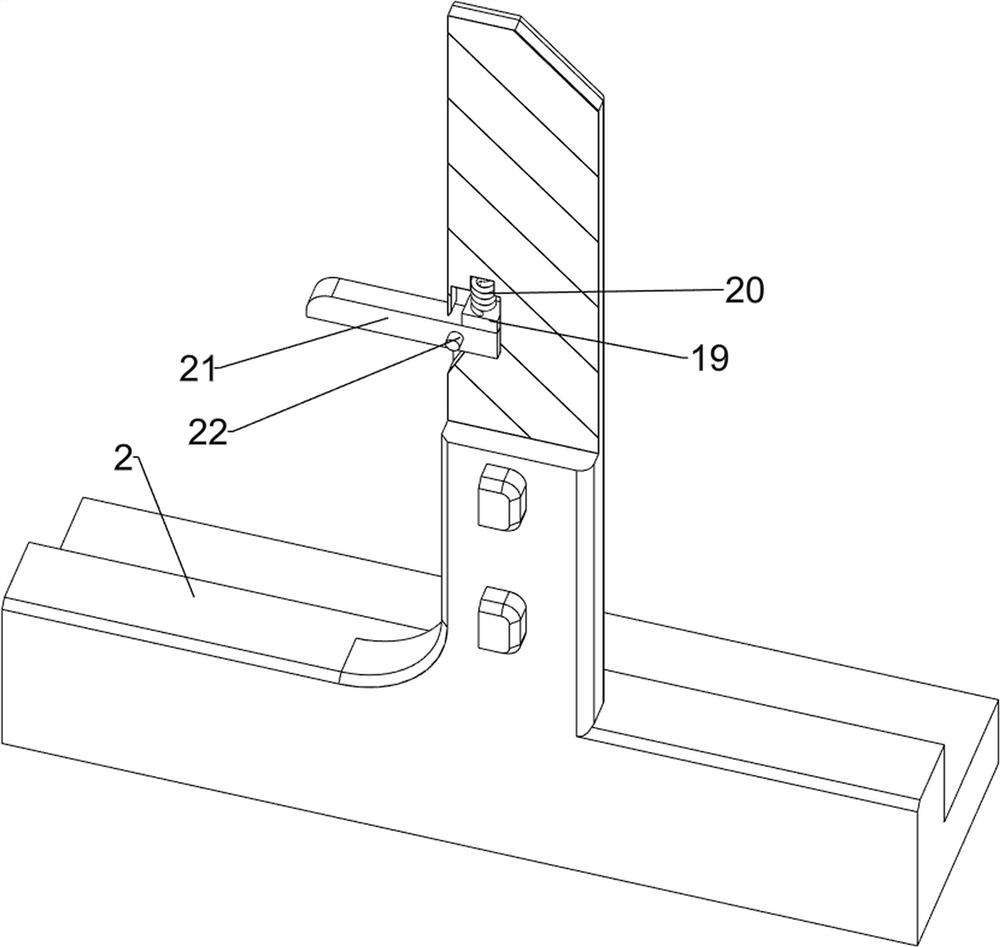

[0037] Such as Figure 4 , Figure 5 , Figure 6 , Figure 7 and Figure 8 As shown, on the basis of Embodiment 2, it also includes a fixed column 9, a first gear 10, a chute plate 11, a second bracket 12, a guide plate 13, a rack 14, a first rotating rod 15 and a movable plate 16. Both of the two first fixing brackets 71 are provided with the fixed column 9 on the back side, and the two fixed columns 9 are provided with the first gear 10 at the back end, and the top of the workbench 3 The front and rear sides are provided with the chute plate 11, and the two fixed columns 9 are slidably matched with the two chute plates 11. The guide plates 13 are provided on each of the second brackets 12, the racks 14 are provided on the upper side of the two guide plates 13, the two first gears 10 and the two racks 14 Cooperating with each other, the left sides of the two guide plates 13 are rotatably provided with the first rotating rods 15 , and the two first rotating rods 15 are re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com