Galvanized iron alloy door polishing device

A polishing device and ferroalloy technology, which is applied to grinding drive devices, grinding/polishing equipment, machine tools with surface polishing, etc., can solve the problems of inability to polish the alloy door, low polishing efficiency, etc., so as to reduce labor intensity and save energy. Cleaning procedures to avoid over-sanding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

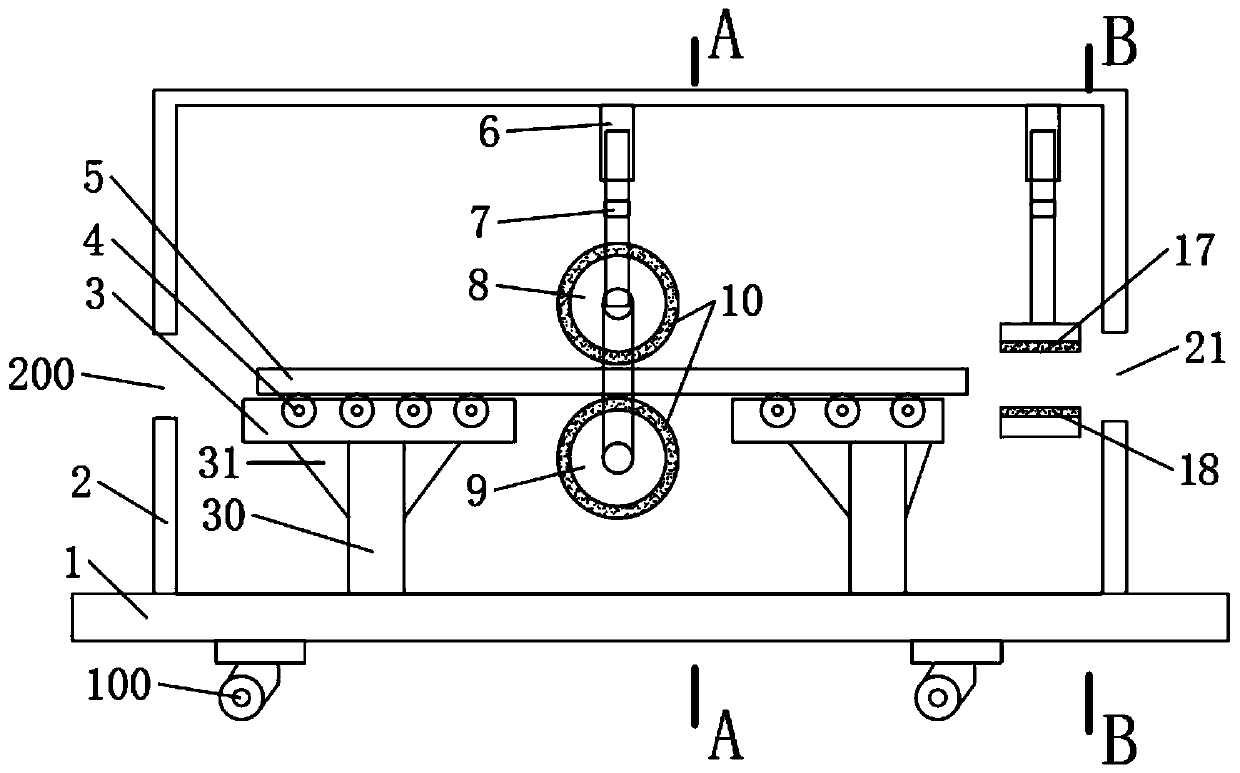

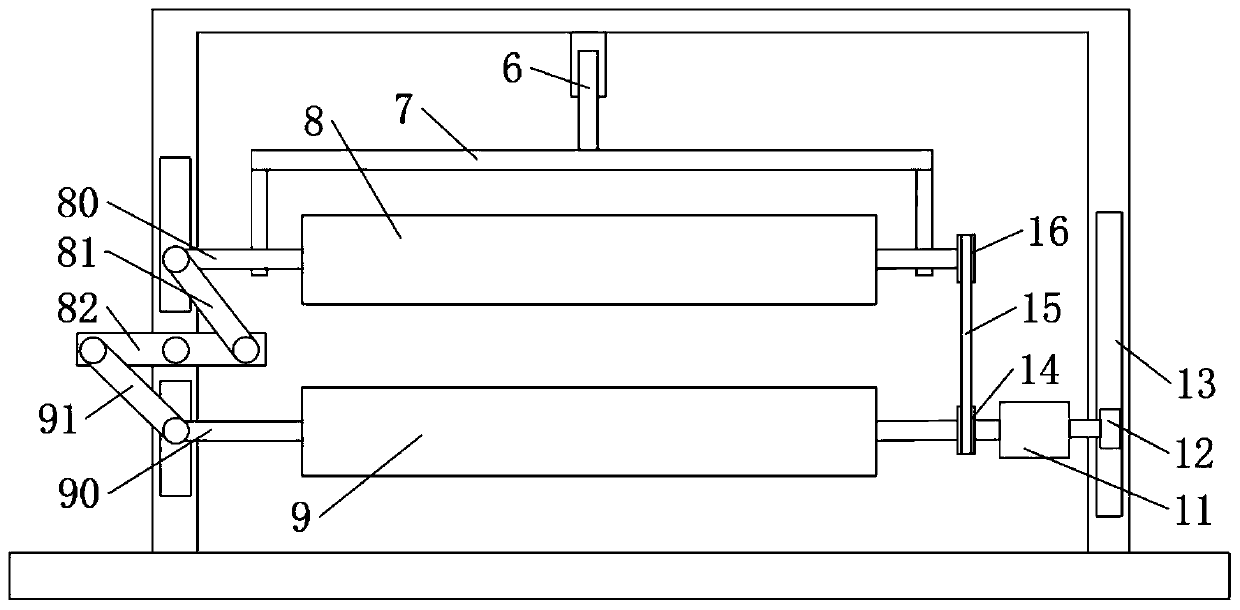

[0021] Such as Figure 1-4 As shown, a galvanized ferroalloy door polishing device includes a base 1, a housing 2 is arranged on the base 1, a material inlet 200 and a material outlet 21 are arranged on the housing 2, and the housing 2 Polishing device is installed inside, and described polishing device comprises upper polishing wheel 8 and lower polishing wheel 9, and described upper polishing wheel 8 and lower polishing wheel 9 are provided with polishing layer 10, and described upper polishing wheel 8 and lower polishing wheel 9 A polishing table 3 is arranged between them, and the polishing table 3 is installed on a support column 30, a rib 31 is arranged between the polishing table 3 and the support column 30, and a conveying wheel 4 is provided on the polishing table 3, so The transmission wheel 4 is connected to the power unit, and it is characterized in that the upper polishing wheel 8 is connected with the first mounting frame 7, the first mounting frame 7 is connecte...

Embodiment 2

[0031] This embodiment is a further improvement and limitation of embodiment 1 on the basis of embodiment 1.

[0032] A galvanized iron alloy door polishing device, including all parts in embodiment 1, also includes:

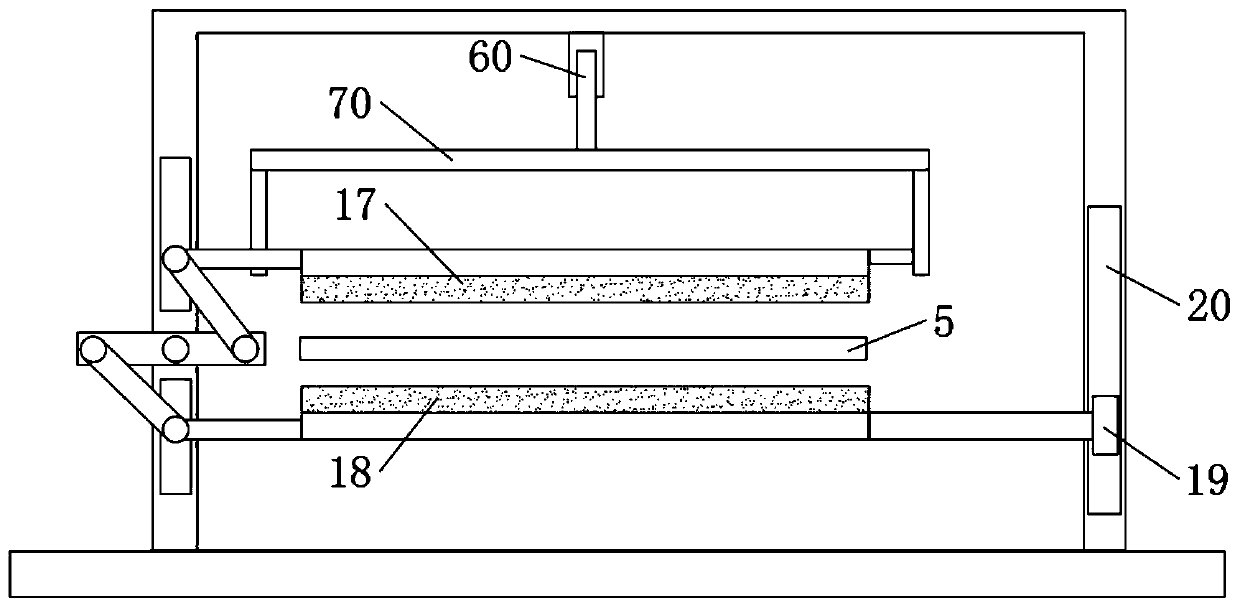

[0033] A cleaning device is provided on the right side of the polishing device, and the cleaning device includes an upper cleaning plate 17 and a lower cleaning plate 18 .

[0034] Specifically, the cleaning device can clean the polished alloy door 5 to remove debris left after surface polishing.

[0035] Further, the upper cleaning plate 17 is connected to the second hydraulic column 60 through the second mounting frame 70, the second sliding block 19 is arranged on the lower cleaning plate, and the lower cleaning plate 18 is connected to the housing through the second sliding block 19. The second sliding groove 20 on the body 2 is slidably connected.

[0036] Further, soft cleaning cloths are provided on the upper cleaning plate 17 and the lower cleaning pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com