Suvorexant tablet and preparation method thereof

A technology of Suwoleisheng and micro-powder, which is applied in the direction of pharmaceutical formula, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of poor dissolution performance of Suwoleisheng medicine, and achieve improvement Absorption rate and bioavailability, enhanced bioavailability, effect of increased absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of the Suvoryxan solid dispersion comprises: micronizing Suvoryxan to obtain a Suvoryxan micropowder with a D90 of less than 30 μm, mixing 5-15 parts by weight of the Suvoryxan micropowder and 30-40 parts by weight Parts of copovidone were mixed uniformly, hot-melt extruded, and crushed to 60 mesh to obtain Suvorexan solid dispersion.

[0033] Wherein, the disintegrant is at least one of sodium carboxymethyl starch, croscarmellose sodium, low-substituted hydroxypropyl cellulose, and crospovidone.

[0034] The lubricant is at least one of magnesium stearate, calcium stearate, micronized silica gel and hard sodium fumarate.

[0035] The hot-melt extrusion conditions are as follows: the screw speed is 100-300rpm, the temperature is 160-180°C, and the feeding speed is 0.8-1.5kg / h.

[0036] The micropowder treatment includes: putting Suvoryson into the jet mill, the feed rate is 0.5-1.5kg / h, the crushing pressure is 0.7-0.9Mpa, and the Suvoryson micro...

Embodiment 1

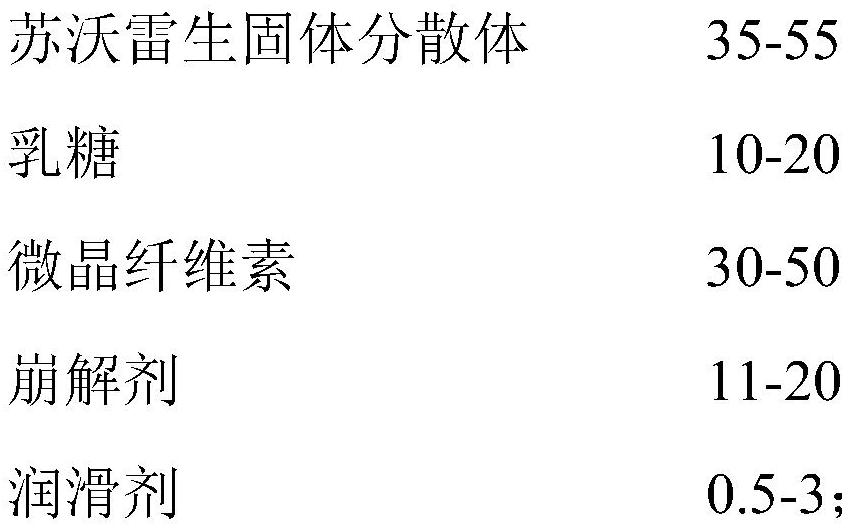

[0043] A kind of Suvoret green sheet, comprises each component of following weight:

[0044]

[0045] The preparation method of the Suvorysan solid dispersion includes: putting Suvorysan into a jet mill YQ100-5, the feed rate is 1.2kg / h, the crushing pressure is 0.8Mpa, and the D90 obtained through cyclone separation is 10 μm 0.9kg of Suvoruisheng micropowder and 3.1kg of copovidone were mixed evenly, and added to the Pharma 11 hot-melt extrusion equipment. The screw speed was 200rpm, the temperature was 170°C, and the feeding speed was 1.0 Extruded under the condition of kg / h, crushed through 60 mesh to obtain Suwo Leisheng solid dispersion;

[0046] The preparation method of suwolai green tablet comprises:

[0047] Add Suvoresan solid dispersion, lactose, microcrystalline cellulose PH102, croscarmellose sodium and micropowder silica gel into the three-dimensional mixing equipment and mix for 40 minutes; the mixed materials are compressed with a rotary tablet machine to o...

Embodiment 2

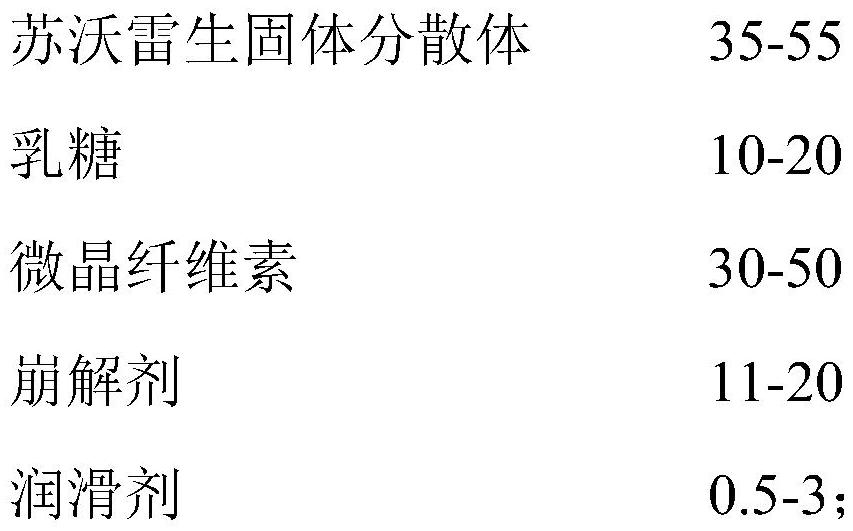

[0049] A kind of Suvoret green sheet, comprises each component of following weight:

[0050]

[0051] The preparation method of the Suvorysan solid dispersion includes: putting Suvorysan into a jet mill YQ100-5, the feed rate is 1.2kg / h, the crushing pressure is 0.8Mpa, and the D90 obtained through cyclone separation is 26 μm 1.2kg of Suvoruisheng micropowder and 2.4kg of copovidone were evenly mixed, and then added to the Pharma 11 hot-melt extrusion equipment. The screw speed was 200rpm, the temperature was 160°C, and the feeding speed was 1.0 Extruded under the condition of kg / h, crushed through 60 mesh to obtain Suwo Leisheng solid dispersion;

[0052] The preparation method of suwolai green tablet comprises:

[0053] Add Suvoresan solid dispersion, lactose, microcrystalline cellulose PH102, croscarmellose sodium and micropowder silica gel into the three-dimensional mixing equipment and mix for 40 minutes; the mixed materials are compressed with a rotary tablet machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com