Method for preparing super-absorbent resin

一种超吸收性、聚合物的技术,应用在吸收垫、医药科学、假体等方向,能够解决超吸收性聚合物分离、吸收度减小、物理特性冲突等问题,达到物理特性改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A method of preparing a superabsorbent polymer according to an embodiment of the present invention may include the following steps:

[0027] performing thermal polymerization or photopolymerization of a monomer composition comprising a water-soluble ethylenically unsaturated monomer, an internal crosslinking agent and a polymer to prepare a hydrogel polymer having a gel strength of 10000Pa to 13000Pa Initiator;

[0028] Coarsely pulverizing the hydrogel polymer;

[0029] drying the coarsely pulverized hydrogel polymer;

[0030] comminuting the dried polymer; and

[0031] The pulverized polymer is mixed with a surface crosslinking agent to perform a surface crosslinking reaction of the mixture.

[0032] The present inventors continued research on superabsorbent polymers exhibiting high absorption rate and liquid permeability while having high centrifuge retention capacity, and they found that the hydrogel polymer as the matrix resin of superabsorbent polymers When th...

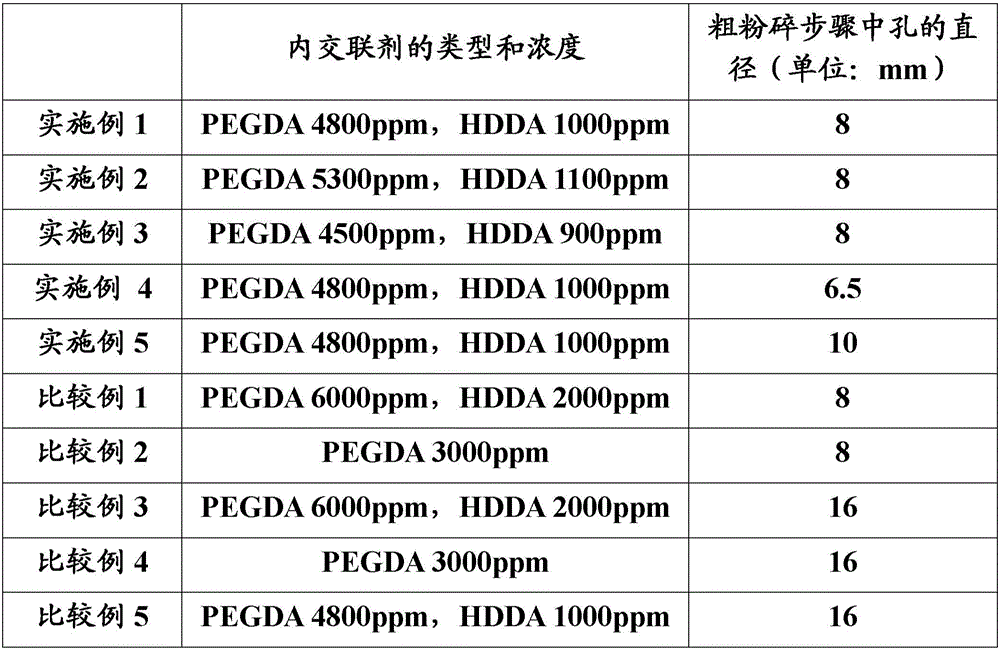

Embodiment 1

[0122] In a 2L glass reactor surrounded by a jacket (heating medium pre-cooled at 25°C circulated through the jacket), 450 g of acrylic acid was mixed with 8 g of 0.5% by weight IRGACURE819 initiator diluted in acrylic acid, and 50 g of acrylic acid was injected. Diluted 5% by weight polyethylene glycol diacrylate (PEGDA, molecular weight 598g / mol, curing dose 200mJ / cm 2 ), and inject 10g of 5% by weight of 1,6-hexanediol diacrylate diluted with acrylic acid (molecular weight is 226g / mol, curing dose is 320mJ / cm 2 ), and then slowly add 660 g of 32% by weight caustic soda solution dropwise.

[0123] After confirming that the temperature of the mixture was raised to 80°C or higher by the heat of neutralization generated when the two solutions were mixed, the mixture was left to stand until the reaction temperature reached 40°C. When the reaction temperature reached 40° C., 50 g of 2% sodium persulfate solution diluted with water was injected.

[0124] The solution was poured ...

Embodiment 2

[0130] A superabsorbent polymer was prepared in the same manner as in Example 1, except that 55 g of 5% by weight polyethylene glycol diacrylate diluted with acrylic acid was used instead of 50 g thereof in Example 1, and 11 g of acrylic acid diluted Diluted 5% by weight 1,6-hexanediol diacrylate was substituted for 10 g thereof in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| gel strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com