Novel semi-conductive non-water-blocking buffer cushion layer high-voltage power cable

A high-voltage power and buffer layer technology, which is used in the manufacture of power cables with shielding layers/conducting layers, insulated cables, cables/conductors, etc., can solve problems such as buffer layer ablation, and achieve the effect of improving safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

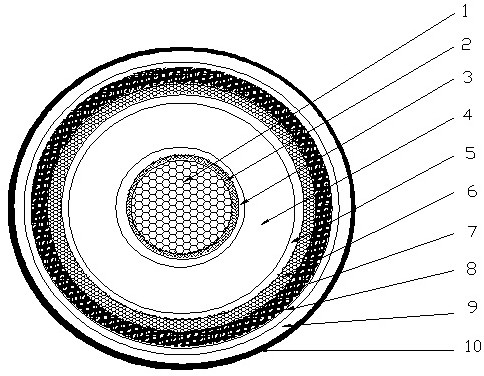

[0066] Example 1: A new type of semi-conductive non-water-blocking cushion layer high-voltage power cable, such as figure 1 As shown, the cable includes a conductor, and the conductor is surrounded by a semi-conductive nylon tape, an ultra-clean XLPE insulation layer, a semi-conductive non-water-blocking buffer tape, a corrugated aluminum sheath, cable pitch, an insulating outer sheath, and a graphite coating. , An ultra-smooth semi-conductive layer is set between the inner layer of the ultra-clean XLPE insulating layer and the wrapped semi-conductive nylon tape, and an ultra-smooth insulating shielding layer is set between the outer layer of the ultra-clean XLPE insulating layer and the semi-conductive non-water-blocking buffer belt.

[0067] The corrugated aluminum sheath is embedded in the semi-conductive non-water-blocking buffer tape, and the negative gap between the corrugated aluminum sheath and the semi-conductive non-water-blocking buffer tape in the 110kV high-voltage...

Embodiment 2

[0073] Example 2: The difference from Example 1 is that a 220kV high-voltage power cable is prepared, and the negative gap between the corrugated aluminum sheath and the semiconductive non-water-blocking buffer zone is 1.0 mm. Regarding the ultra-clean XLPE insulation layer, take 100 parts of linear low-density polyethylene, 40 parts of full-density polyethylene, 3 parts of antioxidant, 1 part of cross-linking agent, and the melt index of low-density polyethylene is between 1.5-1.6 , the melt index of full-density polyethylene is 1.8-2.0, and the twin-screw extruder is fully mixed, dispersed, and homogenized at a temperature of 160°C to obtain a molten material, which is melt-filtered; underwater granulation, and filtered above 50 microns Impurity particles are used to produce ultra-clean premix; the temperature range of melt filtration is 140°C, and high-density filter screen is used to filter impurities above 100 microns; the antioxidant is antioxidant BHT.

Embodiment 3

[0074] Example 3: The difference from Example 1 is that a 220kV high-voltage power cable is prepared, and the negative gap between the corrugated aluminum sheath and the semiconductive non-water-blocking buffer zone is 1.0 mm. Regarding the ultra-clean XLPE insulation layer, take 100 parts of linear low density polyethylene, 30 parts of full density polyethylene, 4 parts of antioxidant, 1 part of crosslinking agent, and the melt index of low density polyethylene is between 1.7-1.8 , the melt index of full-density polyethylene is 1.9-2.0, and the twin-screw extruder is fully mixed, dispersed, and homogenized at a temperature of 160°C to obtain a molten material, which is melt-filtered; underwater granulation, and filtered above 50 microns Impurity particles are used to produce ultra-clean premix; the temperature range of melt filtration is 130°C, and the melt filter uses a high-density filter to filter impurities above 100 microns; the antioxidant is the antioxidant BHT.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com