Device and method for sputtering and depositing metal on surface of magnetic powder material

A magnetic powder, sputtering deposition technology, applied in the direction of sputtering coating, metal processing equipment, metal material coating technology, etc., can solve the problem that it is difficult to realize the metal deposition of magnetic powder materials, and the surface deposition of magnetic powder materials cannot be realized height uniformity etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

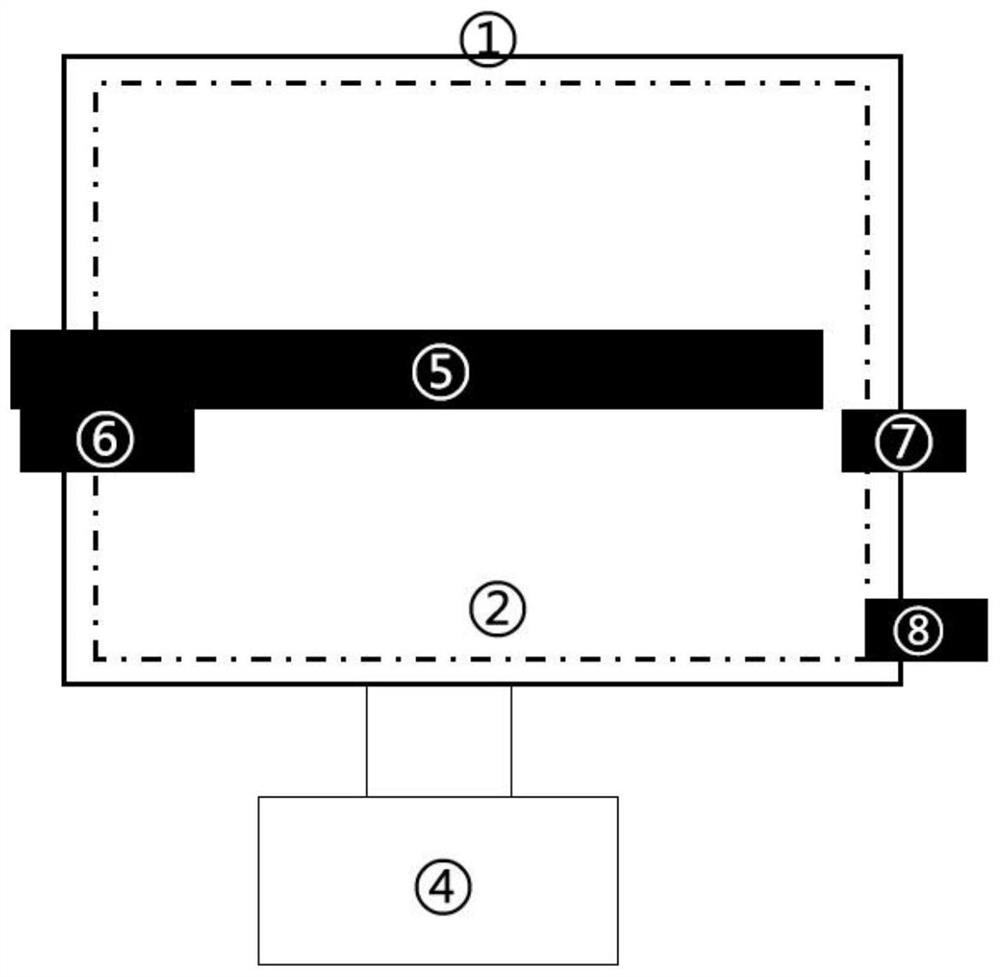

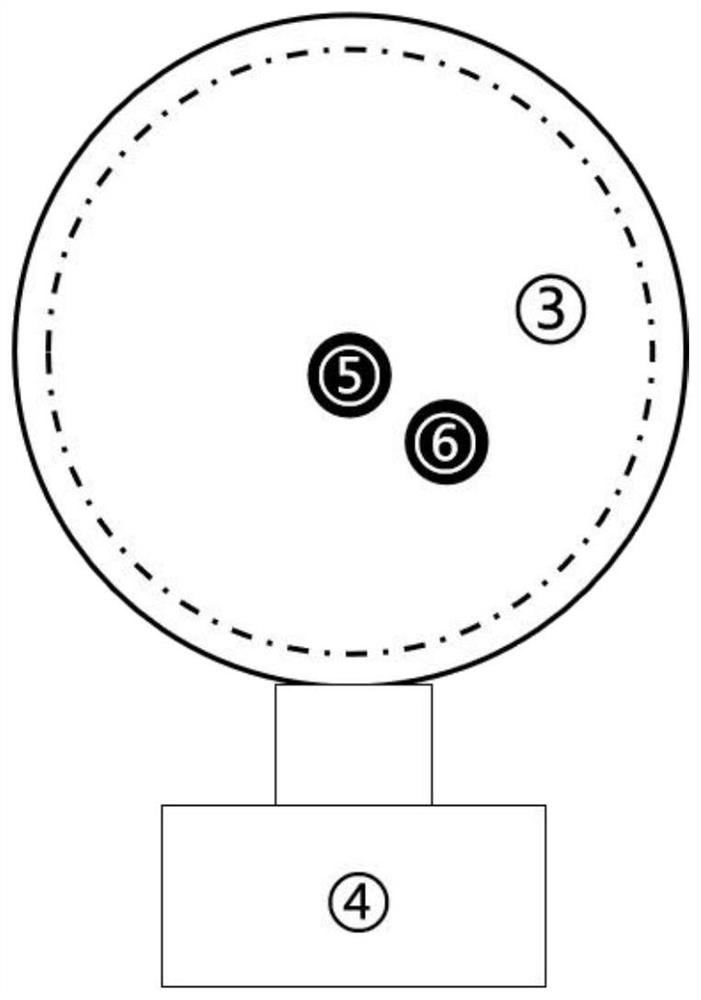

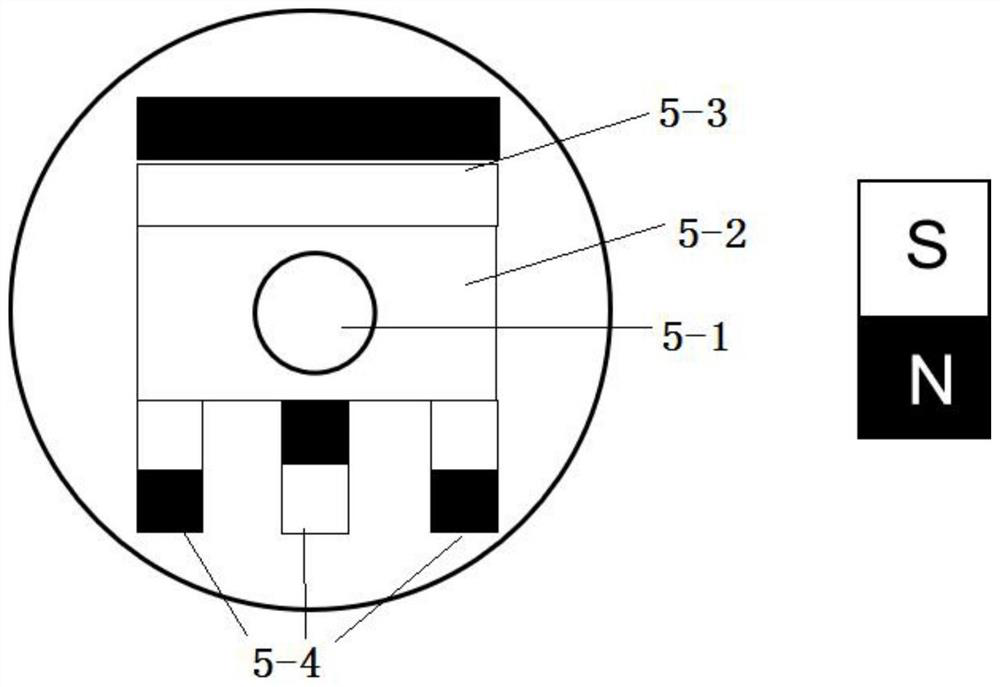

[0098] This embodiment provides a device for depositing metal by sputtering on the surface of a magnetic powder material, which includes a cylindrical vacuum chamber 1, and the size of the vacuum chamber 1 is The vacuum chamber 1 is provided with a first vacuum chamber door and a second vacuum chamber door. The first vacuum chamber door 3 and the second vacuum chamber door correspond to the two open ends of the sample drum 2. The first vacuum chamber door 3 and the second vacuum chamber door are clam-style side-opening doors; including vacuum pump group 4, vacuum pump group 4 uses FF250-2000 molecular pump + 18L / min mechanical pump, which meets the requirements of 40min to vacuum 2×10 -3 Pa; including a magnetron sputtering target 5, the magnetron sputtering target 5 goes deep into the sample cylinder 2, and the magnetron sputtering target 5 is arranged on the inner wall of the first vacuum chamber door 3 of the vacuum chamber , the magnetron sputtering target 5 has a built-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com