Novel phase change system of long-chain hydrocarbon and long-chain alkyl polymer

A long-chain hydrocarbon and polymer technology, which is applied in the field of new phase change systems for long-chain hydrocarbons and long-chain hydrocarbon-based polymers, can solve the problems of limited use range and low heat resistance temperature, and achieve high safety and good thermal stability. , Controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

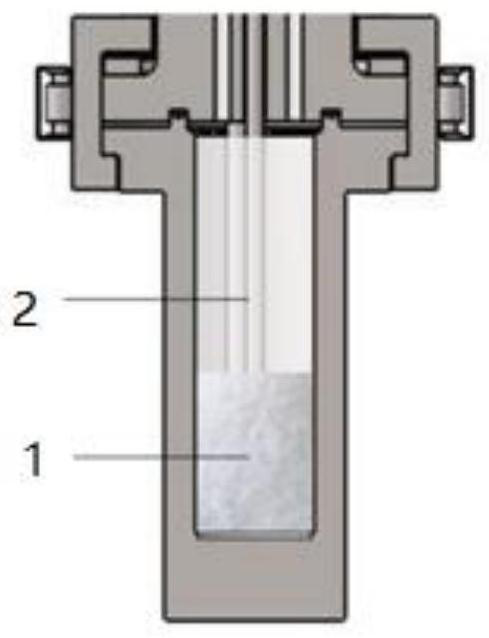

Image

Examples

Embodiment 1

[0027] The container volume of the phase change system is 100mL, the phase change material is eicosane, the volume of the phase change material accounts for 1 / 8 of the volume of the phase change system, the phase builder is nitrogen, the initial pressure of nitrogen is 1MPa, and the original heating rate is 15 °C / min, the set temperature is 230 °C. When the temperature of the phase change system rises to 230 °C, the external heat supply is stopped, and the phase change material is heated to a peak temperature of 310 °C at a heating rate of about 120 °C / min due to the heat released by the phase change inside the phase change material.

Embodiment 2

[0036] The volume of the phase change system container is 100mL, the phase change material is octadecane, the volume of the phase change material accounts for 1 / 9 of the volume of the phase change system, the upper atmosphere pressure is provided by nitrogen, the initial pressure of nitrogen is 1MPa, and the original heating rate is 15°C / min, the set temperature is 250°C. When the temperature of the phase change system rises to 250 °C, the external heat supply is stopped, and the phase change material is heated to a peak temperature of 340 °C at a heating rate of about 150 °C / min due to the heat released by the phase change inside the phase change material.

Embodiment 3

[0038] The volume of the phase change system container is 100mL, the phase change material is polyethylene, the volume of the phase change material accounts for 1 / 7 of the volume of the phase change system, the upper atmosphere pressure is provided by nitrogen, the initial pressure of nitrogen is 1MPa, and the original heating rate is 15°C / min, the set temperature is 340°C. When the temperature of the phase change system rises to 340°C, the external heat supply is stopped, and the phase change material is heated to a peak temperature of 410°C at a heating rate of about 110°C / min due to the heat released by the phase change inside the phase change material. The depolymerization reaction of ethylene occurs at this temperature, and the same degree of self-exothermic phenomenon does not exist in the second heating process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com