Flame-retardant silicone sealant for aluminum alloy doors and windows and preparation method thereof

A technology of silicone sealant and aluminum alloy doors and windows, applied in the field of sealant, can solve the problems of poor comprehensive performance and long service life of silicone sealant, and achieve the requirements of mass production, easy operation and improved dispersibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

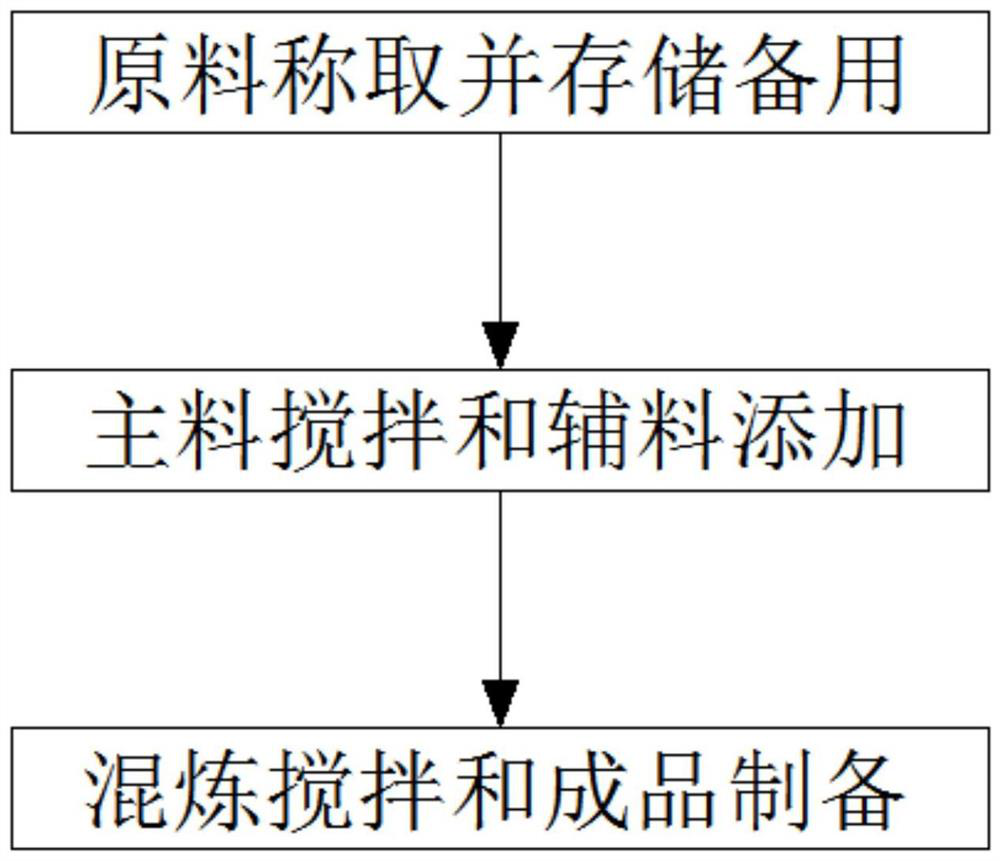

Method used

Image

Examples

Embodiment 1

[0022] This embodiment provides a flame-retardant silicone sealant for aluminum alloy doors and windows, including the following raw materials in parts by weight: 80 parts of polydimethylsilicone oil, 10 parts of polyurethane, 5 parts of crosslinking agent, and 5 parts of plasticizer parts, 10 parts of mixed filler, 5 parts of calcium carbonate, 7 parts of catalyst, 7 parts of thixotropic agent, 6 parts of coupling agent, 7 parts of phosphate ester flame retardant, 8 parts of tackifier and 10 parts of auxiliary agent, of which poly The viscosity of methyl silicone oil is 1000mPa·s, and the dielectric constant is 2.76. The crosslinking agent is methyltriacetoneximosilane, and the mixed filler is composed of white carbon black, quartz powder, glass fiber and silicon dioxide. The mass ratio is 2:1:1:2, the catalyst is prepared by mixing stannous octoate and dibutyltin dilaurate at a mass ratio of 1:1, and the thixotropic agent is a polyamide compound , the plasticizer is a phthal...

Embodiment 2

[0028]This embodiment provides a flame-retardant silicone sealant for aluminum alloy doors and windows, including the following raw materials in parts by weight: 100 parts of polydimethylsilicone oil, 20 parts of polyurethane, 10 parts of crosslinking agent, and 7 parts of plasticizer parts, 20 parts of mixed fillers, 10 parts of calcium carbonate, 9 parts of catalysts, 10 parts of thixotropic agents, 8 parts of coupling agents, 13 parts of phosphate ester flame retardants, 12 parts of tackifiers and 15 parts of additives. The viscosity of methyl silicone oil is 5000mPa·s, the dielectric constant is 2.78, the crosslinking agent is methyl tributylketoxime silane, and the mixed filler is composed of white carbon black, quartz powder, glass fiber and silicon dioxide Prepared by mixing at a mass ratio of 2:1:1:2, the catalyst is prepared by mixing stannous octoate and dibutyltin dilaurate at a mass ratio of 1:1, and the thixotropic agent is polyamide compound, the plasticizer is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com