Process for producing collagen polypeptide by physical and biological double-cutting one-step method

A collagen polypeptide, biological technology, applied in the field of bioengineering, to achieve the effect of excellent product quality, high purity, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

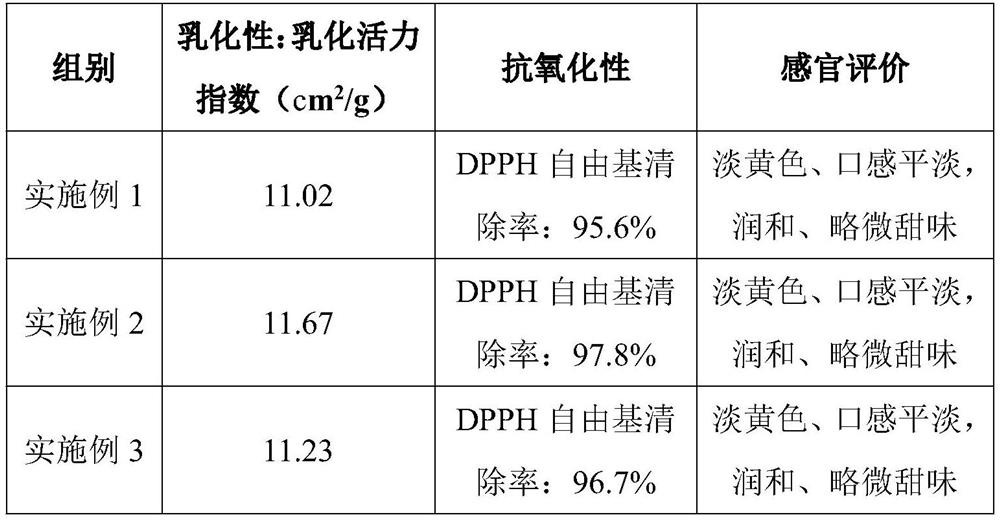

Examples

Embodiment 1

[0045] A process for producing collagen polypeptides in one step with physical and biological double cleavage, comprising the following steps:

[0046] (1) 11kg of tilapia is put into the frozen meat grinder and twisted into meat-like raw material, then add 1.6‰ ascorbic acid solution to the meat-like raw material, and add 380kg of pure water, at a speed of 60r / min Stir for 7 minutes to obtain the anti-oxidation tilapia mixed slurry;

[0047] (2) Adding quality to the antioxidant tilapia mixed slurry obtained in step (1) is 2.5‰ cyclodextrin, stirring for 5min at a rotating speed of 100r / min to obtain a uniform mixture, and then the uniform mixture Drop into the colloid mill for grinding, the grinding temperature is 42°C, and the fineness is 200 mesh tilapia slurry;

[0048] (3) Enzymolysis: the aquatic animal slurry prepared in step (2) is lowered to room temperature, the pH value is adjusted to 5.2, and compound enzyme a of 2.5% of the substrate mass is added, and the compo...

Embodiment 2

[0056] A process for producing collagen polypeptides in one step with physical and biological double cleavage, comprising the following steps:

[0057] (1) Put 13kg of monkfish into a frozen meat grinder and twist it into meat-like raw materials, then add 1.8‰ ascorbic acid solution to the meat-like raw materials, and add 560kg of pure water, and stir at a speed of 70r / min 6min to obtain the antioxidant monkfish mixed slurry;

[0058] (2) Add cyclodextrin with a quality of 3‰ to the anti-oxidation monkfish mixed slurry obtained in step (1), and stir for 4 minutes at a rotating speed of 120r / min to obtain a uniform mixture, and then put the uniform mixture into Grinding in a colloid mill with a grinding temperature of 45°C to obtain a monkfish slurry with a fineness of 300 mesh;

[0059] (3) Enzymolysis: the aquatic animal slurry prepared in step (2) is lowered to room temperature, the pH value is adjusted to 5.6, and compound enzyme a with 2.8% of the substrate mass is added,...

Embodiment 3

[0067] A process for producing collagen polypeptides in one step with physical and biological double cleavage, comprising the following steps:

[0068] (1) Put 15kg of grass carp into a frozen meat grinder and twist it into a meat-like raw material, then add 2‰ ascorbic acid solution to the meat-like raw material, and add 720kg of pure water, and stir for 5 minutes at a speed of 80r / min , to obtain the antioxidant grass carp mixed pulp;

[0069] (2) To the antioxidant grass carp mixed slurry obtained in step (1), add cyclodextrin with a quality of 3.5‰, and stir for 3 minutes at a rotating speed of 150r / min to obtain a uniform mixture, and then put the uniform mixture into the colloid Grinding in the mill, the grinding temperature is 48°C, and the grass carp slurry with a fineness of 300 mesh is obtained;

[0070] (3) Enzymolysis: the aquatic animal slurry prepared in step (2) is lowered to room temperature, the pH value is adjusted to 6.0, and compound enzyme a with 2.9% of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com