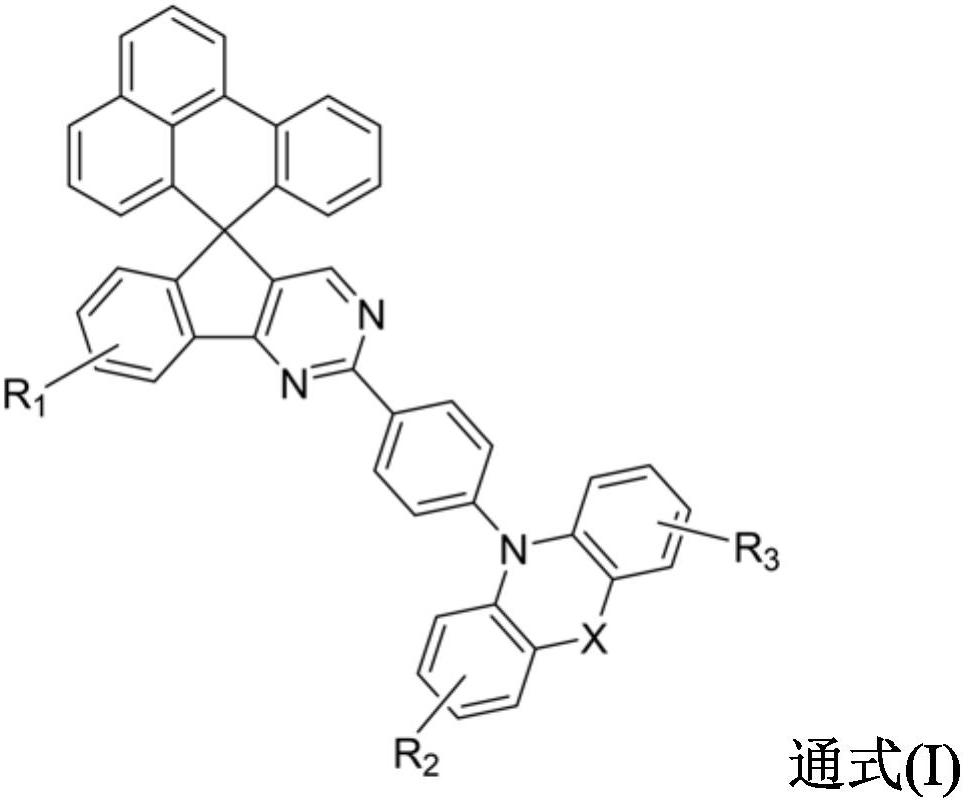

2, 4-diazaspirofluorene derivative and electronic device

A technology of fluorene derivatives and diazaspiro, which is applied in the field of organic optoelectronic materials to achieve the effects of excellent electron transport performance, reduced driving voltage, and low driving voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the synthesis of compound 1-1

[0039] The synthetic route of intermediate M1 is as follows:

[0040]

[0041]Under the protection of nitrogen, 1-bromo-8-phenylnaphthalene (2.5 g, 8.9 mmol) and 150 mL of anhydrous tetrahydrofuran were added to a dry and clean 250 mL three-necked flask, and stirred to dissolve at room temperature. The system was cooled to -78°C, and 3.9 mL (2.5 M, 9.8 mmol) of n-butyllithium was added dropwise at this temperature, and stirring was continued at this temperature for 1.5 h after the addition was completed. Then, 3-(4-bromophenyl)-2,4-diazafluorenone (2.7g, 8.1mmol) was added in one go. After the addition, the cooling bath was removed, and the reaction returned to room temperature by itself and continued to stir overnight. . After the reaction, it was washed with water, dried, and spin-dried to obtain a white solid.

[0042] Transfer the above white solid to a 250mL single-necked bottle equipped with a reflux condenser, a...

Embodiment 2

[0046] Embodiment 2: the synthesis of compound 2-3

[0047] The synthetic route of compound 2-3 is as follows:

[0048]

[0049] Under nitrogen protection, intermediate M1 (2.6g, 5mmol), 5,7-dihydro-7,7-dimethyl-indeno[2,1-B]carbazole (1.4 g, 5mmol), palladium acetate (11mg, 0.05mmol), tri-tert-butylphosphine tetrafluoroborate (29mg, 0.1mmol), sodium tert-butoxide (960mg, 10mmol) and 120mL toluene, refluxed and stirred for 12 hours. After the reaction was complete, the solvent was evaporated, the residue was dissolved with 200 mL of dichloromethane, washed with water, the organic layer was separated, the aqueous layer was extracted twice with 15 mL of dichloromethane, and the organic layers were combined. After distilling off the solvent, the residue was separated by column chromatography (petroleum ether:dichloromethane=3:1 (V / V)). The solvent was evaporated, and after drying, 2.5 g of a green solid was obtained with a yield of 68%. MS (EI): m / z: 725.28 [M + ]. Anal.c...

Embodiment 3

[0050] Embodiment 3: the synthesis of compound 3-3

[0051] The synthetic route of compound 3-3 is as follows:

[0052]

[0053] Under nitrogen protection, intermediates M1 (2.6g, 5mmol), M2 (3.2g, 5.2mmol), palladium acetate (11mg, 0.05mmol), tri-tert-butylphosphine tetrafluoroborate were successively added to a 250mL Schlenk bottle (29mg, 0.1mmol), sodium tert-butoxide (960mg, 10mmol) and 120mL toluene, reflux and stir for 12 hours. After the reaction was complete, the solvent was evaporated, the residue was dissolved with 200 mL of dichloromethane, washed with water, the organic layer was separated, the aqueous layer was extracted twice with 15 mL of dichloromethane, and the organic layers were combined. After distilling off the solvent, the residue was separated by column chromatography (petroleum ether:dichloromethane=4:1 (V / V)). The solvent was evaporated, and after drying, 3.5 g of a green solid was obtained with a yield of 65%. MS(EI): m / z: 1065.40[M + ]. Anal....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com