Machining process and device of gear pump

A processing device and processing technology technology, which is applied in the direction of positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of cumbersome processing of pump cores and low processing efficiency, so as to speed up processing efficiency, improve processing efficiency, reduce The effect of retention times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

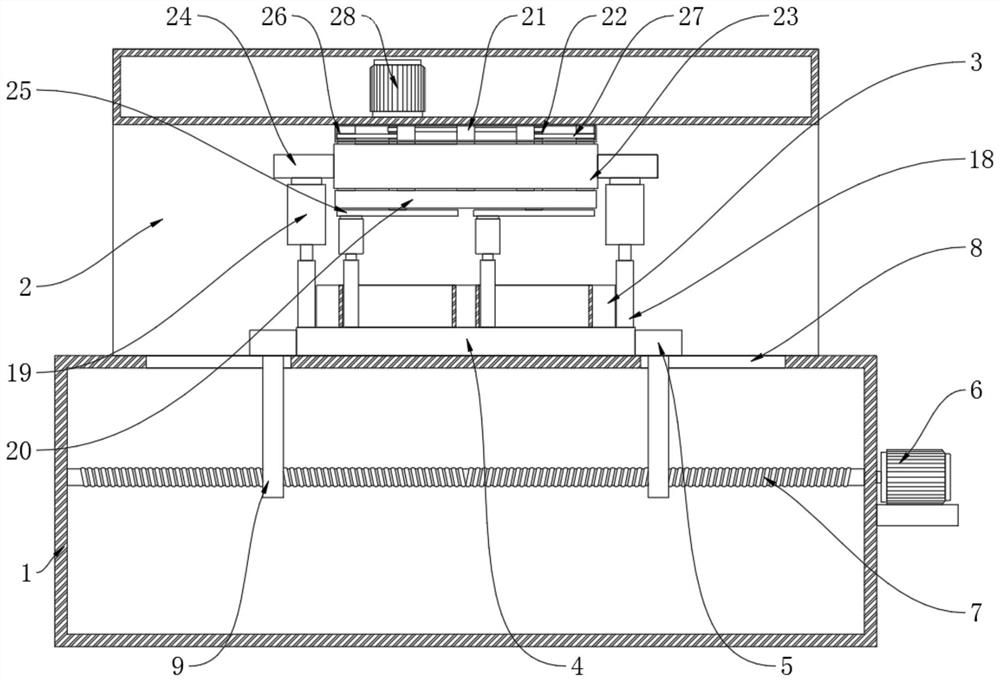

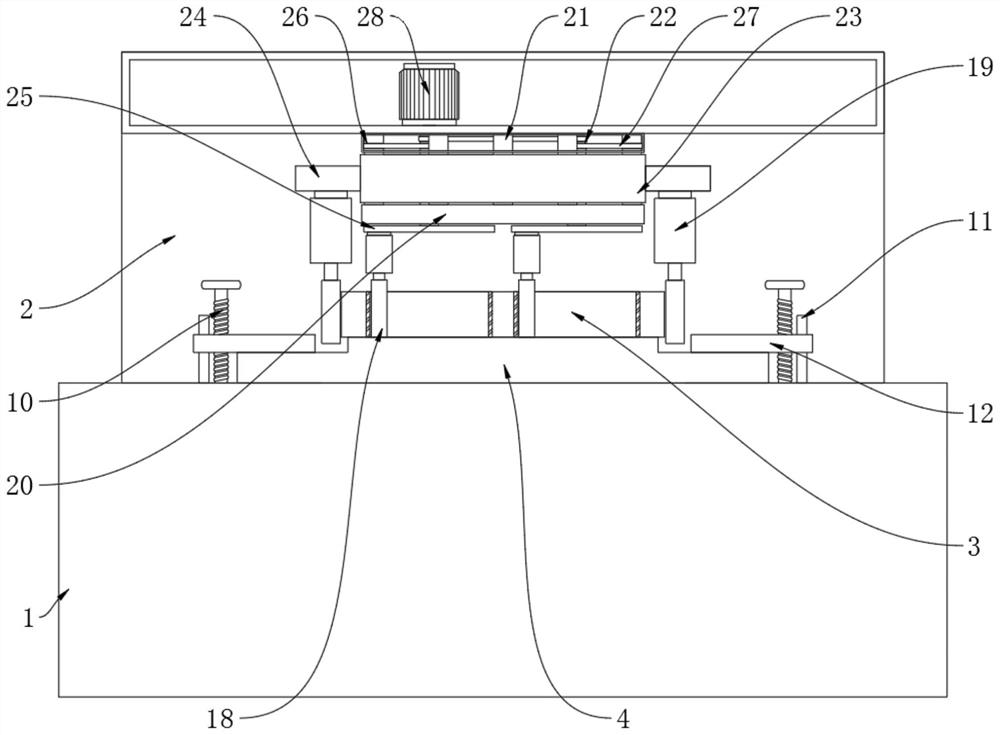

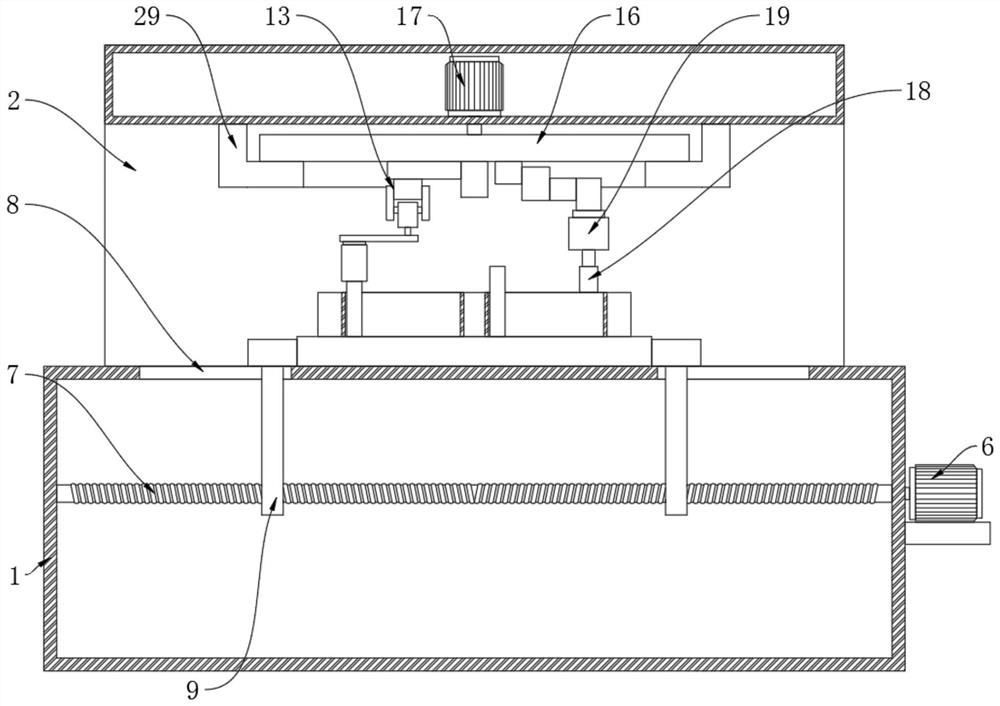

[0032] Please refer to Figure 1 to Figure 3 , a processing device for a gear pump, comprising a processing table 1, a frame 2 is fixedly installed on the top of the processing table 1, a transmission mechanism is provided on the frame 2, a cutting mechanism is provided on the transmission mechanism, and the transmission mechanism is used to drive the cutting mechanism to move , the workbench is also provided with a pump core 3, the bottom of the pump core 3 is glued to the retainer 4 by colloid, and the outside of the retainer 4 is provided with a positioning mechanism, which is used to fix the retainer 4; the cutting mechanism is at least provided with Two, two cutting mechanisms cut the inner hole and the outer wall of the pump core 3 respectively.

[0033] The positioning mechanism can clamp and fix both sides of the retainer 4:

[0034] Specifically, the positioning mechanism includes two clamping plates 5, the outside of the processing table 1 is provided with a positio...

Embodiment 2

[0048] Furthermore, the present invention provides another embodiment: since the retainer 4 is bonded to the bottom of the pump core 3 with colloid, and then the positioning mechanism is used to position the retainer 4, thereby ensuring that the positioning mechanism will not block the external cutting mechanism from The pump core 3 is processed, therefore, multiple cutting mechanisms can be set to process the pump core 3 synchronously,

[0049] Specifically, such as figure 1 and figure 2 , the cutting mechanism comprises a milling cutter 18 and a power motor 19, the output shaft of the power motor 19 is fixedly mounted with a milling cutter 18, and three cutting mechanisms are arranged, and the three cutting mechanisms move synchronously for processing;

[0050] It should be noted that, in the embodiment of the present invention, multiple milling cutters 18 operate synchronously, which can realize synchronous cutting and processing of the two inner holes and the outer wall ...

Embodiment 3

[0052] Further, the transmission mechanism includes two fixed blocks 20, a plurality of rotating shafts 21 and two power shafts 22 are arranged between the two fixed blocks 20, and a transmission belt 23 is installed between the outer sides of the plurality of rotating shafts 21, and the transmission belt 23 The transmission block 24 is fixedly installed, and the bottom ends of the two power shafts 22 extend downward through the fixed block 20, and the bottom ends of the power shafts 22 are fixedly installed with a circular rotating plate 25, and the centers of the two circular rotating plates 25 are respectively Corresponding to the center of the two inner holes of the pump core 3; the inner cavity of the upper fixed block 20 is provided with a deceleration motor 28, the output shaft of the deceleration motor 28 is fixedly connected to the end of one of the power shafts 22, and the two power shafts 22 The driving belt 27 is connected through the shaft disk 26, and the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com