Grain refiner suitable for magnesium alloys with different aluminum contents and preparation method of grain refiner

A technology of grain refiner and refiner, which is applied in the field of grain refinement of magnesium alloys, can solve the problems of unstable refinement effect and limited magnesium alloys, achieve remarkable grain refinement effect and promote the process Longer, more easily controlled effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

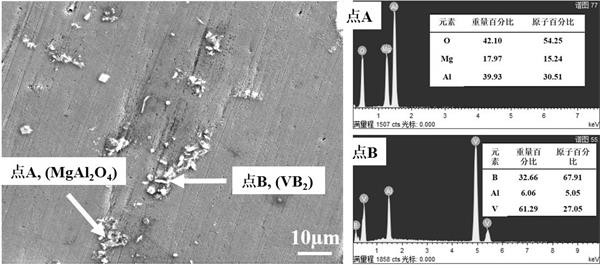

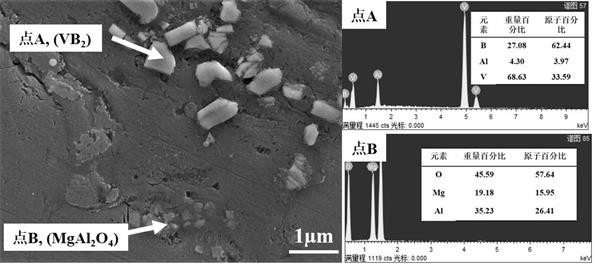

[0039] Example 1: Preparation of a grain refiner suitable for magnesium alloys with different aluminum contents

[0040] A preparation method for a grain refiner suitable for magnesium alloys with different aluminum contents, specifically comprising the following steps:

[0041] (1) Prepare 500 grams of refiner. Pure Al is used as the matrix; V powder is used as the V source; boric acid (H 3 BO 3 ) as B source and O source; pure Mg as Mg source. In order to compensate for element burning loss during the experiment, an additional 5 wt.% of V source, B source, and O source was weighed to supplement the design components. According to the mass percentage of the chemical composition of the alloy, weigh 450 grams of pure aluminum, 21 grams of V powder, and 57 grams of H 3 BO 3 powder and 15 grams of pure magnesium.

[0042] (2) Melting the Al in the step (1) at 750° C. to 850° C. to obtain an Al melt.

[0043] (3) Mix V powder and H in step (1) 3 BO 3 The powder is dried a...

Embodiment 2

[0045] Example 2: Preparation of a grain refiner suitable for magnesium alloys with different aluminum contents.

[0046] A preparation method for a grain refiner suitable for magnesium alloys with different aluminum contents, specifically comprising the following steps:

[0047] (1) Prepare 500 grams of refiner. Using pure Al and Al-V alloy as the matrix; boric acid (H 3 BO 3 ) as B source and O source; pure Mg as Mg source. In order to compensate for the element burning loss during the experiment, an additional 5wt.% B source and O source raw materials were weighed to supplement the design composition. According to the mass percentage of the chemical composition of the alloy, weigh 400 grams of Al-5V alloy, 50 grams of pure Al, and 57 grams of H 3 BO 3 powder and 15 grams of pure magnesium.

[0048] (2) Melting pure Al and Al-V alloy in step (1) at 750°C-850°C to obtain Al-V melt.

[0049] (3) According to the steps in Example 1, H 3 BO 3 Powder is added to the Al-V...

Embodiment 3

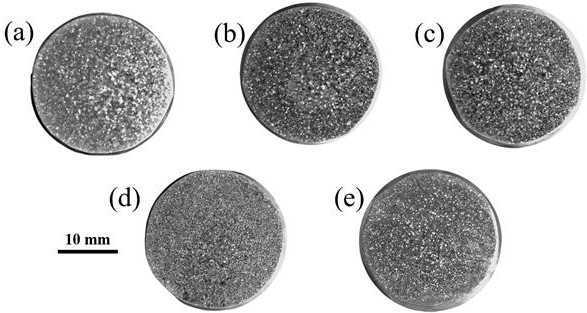

[0050] Example 3: Applying different contents of grain refiners to aluminum-containing magnesium alloys.

[0051] Evaluate the refinement effect of the refiner, the specific method includes the following steps:

[0052] (1) Put 300 grams of pure magnesium in a stainless steel crucible after removing the surface oil and scale, and melt it in a well-type resistance furnace at 730°C to obtain a magnesium melt. Then weigh pure aluminum to stabilize the alloy composition at Mg-3.0wt.%Al (because the subsequent added refiner contains Al, the Al in the refiner is also counted, and the aluminum content should be changed when weighing pure aluminum To stabilize the composition), added to the magnesium melt for 10 minutes, and then cleaned the surface of the melt oxide slag, Mg-3.0wt.%Al melt.

[0053] (2) Weigh 0.2wt.%, 0.5wt.%, 1.0wt.%, 1.5wt.% of the refining agent prepared in Example 2, and add it to the magnesium melt at 730 ° C, and keep it warm for 10 minutes Distribute the ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com