A foamed mud and permeable reactive wall using it as filler

A technology for reacting walls and mud, applied in the field of soil remediation, can solve the problems of waste, pollution, and the inability to reuse supporting materials, and achieve the effect of simplifying the foaming steps and simplifying the overall engineering operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

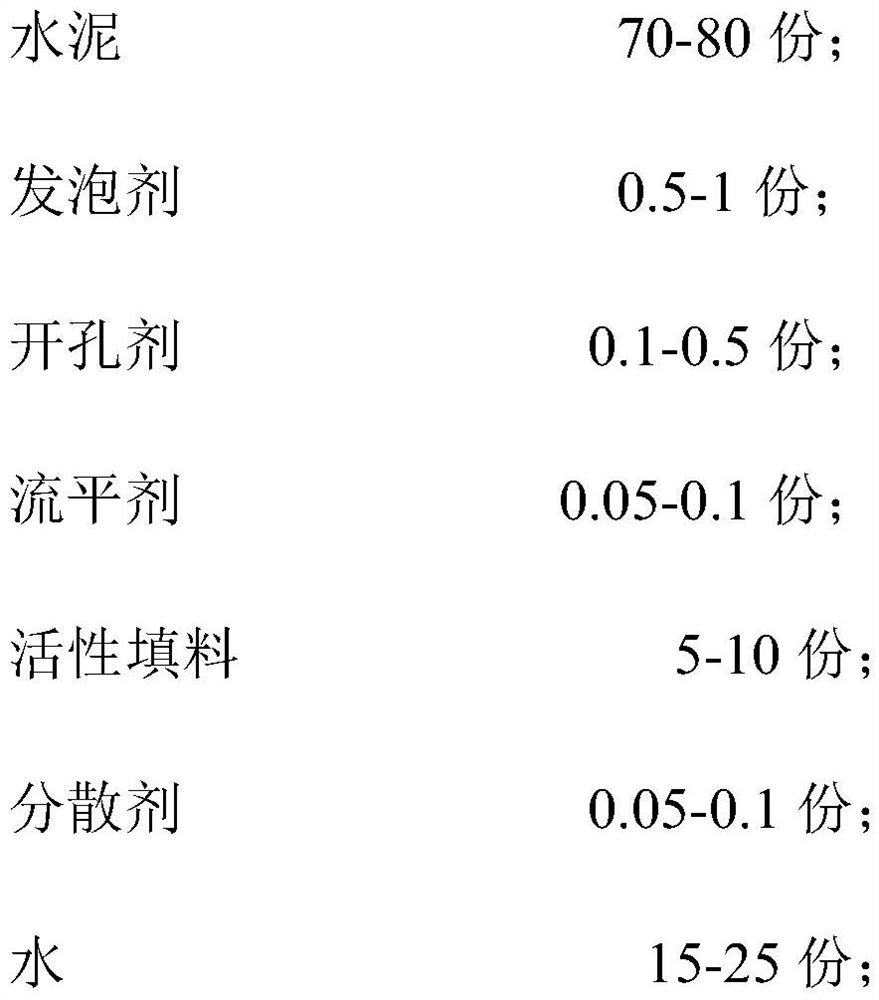

[0050] This embodiment provides a foaming mud, the raw materials of which are 70 kg of Portland cement, 1 kg of azobisisobutyronitrile as a foaming agent, 0.5 kg of polyoxypropylene-ethylene oxide copolyether as a cell opener, and 0.05 kg of an acrylic acid leveling agent. , Active filler 300 mesh zero-valent iron powder 5 kg, dispersant sodium metasilicate 0.05 kg, water 23.4 kg.

[0051] The preparation method is as follows: mix cement and leveling agent powder first, and stir for 10 minutes; add water, add active filler and dispersant at the same time, and mix thoroughly for 30 minutes; add foaming agent and pore-opening agent, and quickly mix for 5 minutes ; Use a foaming machine to whip and foam, and continue to stir for 5 minutes after foaming to obtain foaming mud.

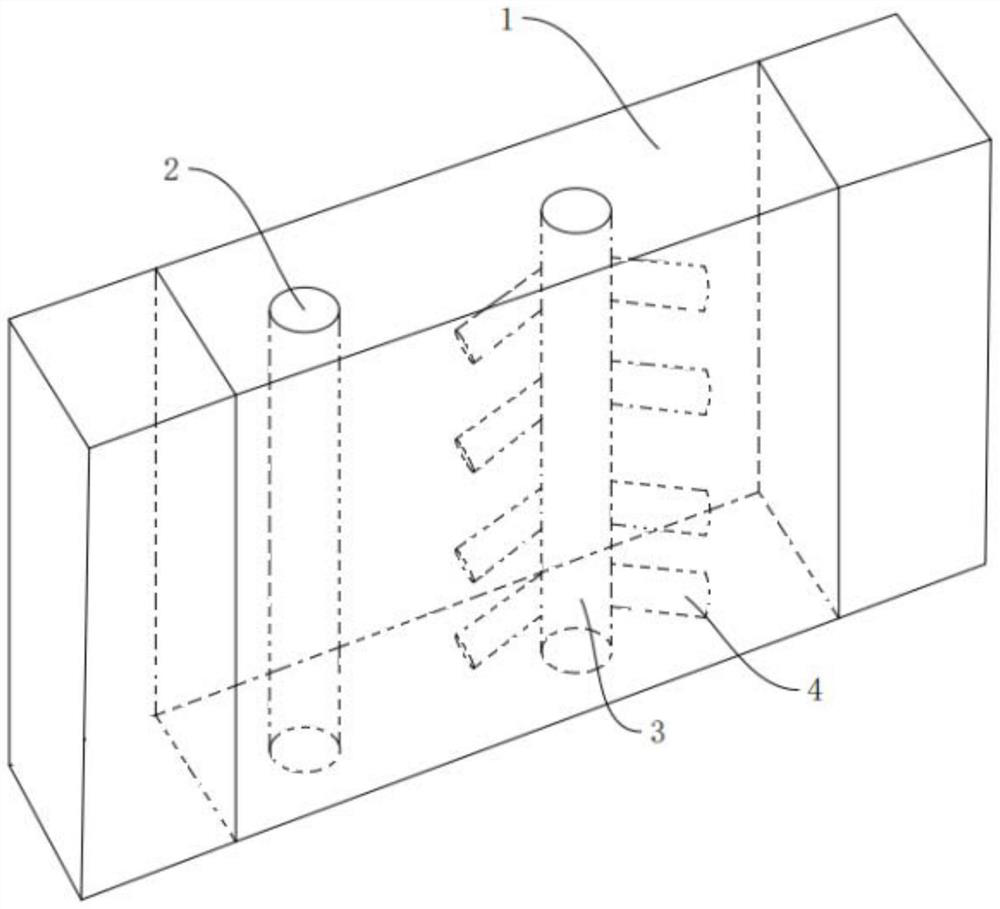

[0052] The present embodiment also provides a permeable reaction wall, using the above-mentioned foamed mud as a raw material, and its specific construction method is as follows:

[0053] (1) Determine the...

Embodiment 2

[0064] This embodiment provides a foaming mud, the raw materials of which are 75 kg of Portland cement, 0.5 kg of dinitrosopentamethylenetetramine as a foaming agent, 0.3 kg of polybutadiene as a cell opener, and a silicone leveling agent. 0.1 kg, active filler 300 mesh iron-carbon mixture 7 kg, dispersant sodium lauryl sulfate 0.05 kg, water 17.05 kg.

[0065] The preparation method is as follows: mix cement and leveling agent powder first, and stir for 5 minutes; add water, add active filler and dispersant at the same time, and mix thoroughly for 25 minutes; add foaming agent and pore-opening agent, and quickly mix for 3 minutes ; Use a foaming machine to whip and foam, and continue to stir for 4 minutes after foaming to obtain foaming mud.

[0066] The present embodiment also provides a permeable reaction wall, using the above-mentioned foamed mud as a raw material, and its specific construction method is as follows:

[0067] (1) Determine the construction of a 40-meter-lo...

Embodiment 3

[0077] This embodiment provides a foamed mud, the raw materials of which are Portland cement 78 kg, foaming agent 4,4-oxobisbenzyl hydrazide 0.5 kg, pore opener polyethylene oxide 0.1 kg, fluorocarbon fluid Leveling agent alkanolamine salt type anionic fluorocarbon leveling agent 0.06 kg, active filler 300 mesh biochar powder 5 kg, dispersant polyacrylamide 0.1 kg, water 16.24 kg.

[0078] The preparation method is as follows: mix cement and leveling agent powder first, and stir for 8 minutes; add water, add active filler and dispersant at the same time, and mix thoroughly for 20 minutes; add foaming agent and pore-opening agent, and quickly mix for 4 minutes ; Use a foaming machine to whip and foam, and continue to stir for 3 minutes after foaming to obtain foaming mud.

[0079] The present embodiment also provides a permeable reaction wall, using the above-mentioned foamed mud as a raw material, and its specific construction method is as follows:

[0080] (1) Determine the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| osmotic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com