Sewage treatment system and method for nitrogen removal and phosphorus recovery

A sewage treatment system and sewage technology, applied in the direction of flotation water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of high TP content in the effluent of the secondary sedimentation tank, waste of phosphorus, Increase the burden of biological phosphorus removal and other problems, achieve the effect of population advantage and activity enhancement, reasonable design, excellent ammonia nitrogen and total nitrogen effluent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

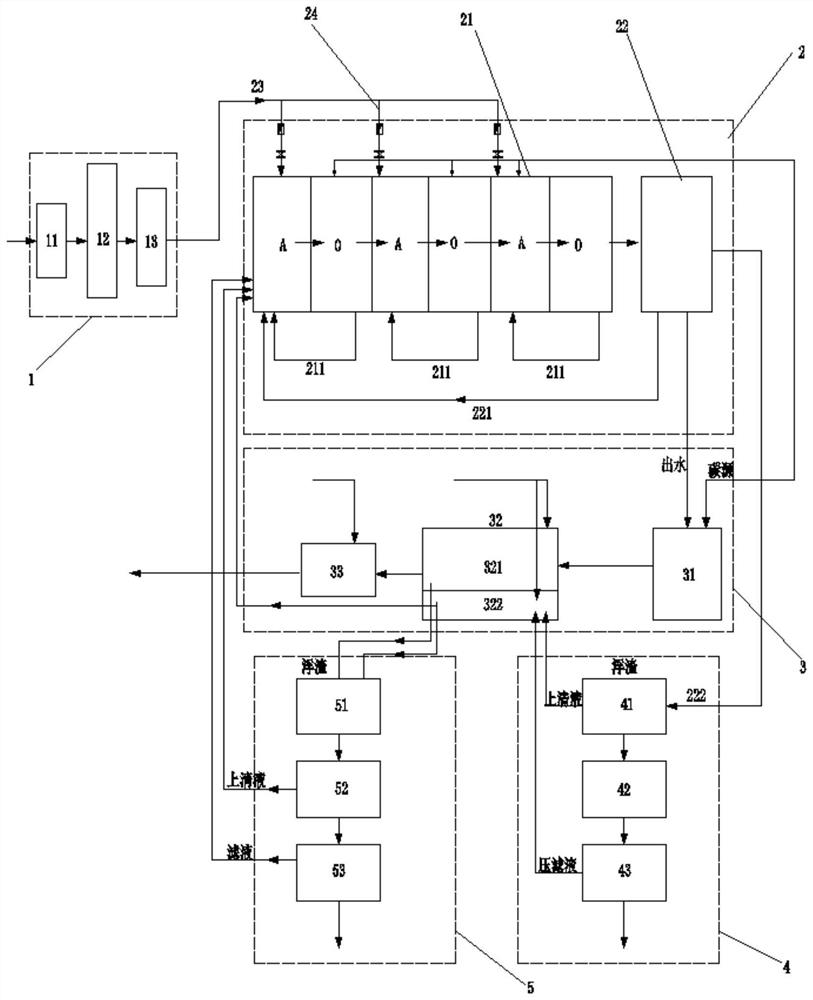

[0032] Such as figure 1 , the present embodiment provides a sewage treatment system for denitrification and phosphorus recovery, including a pretreatment system 1, a biological treatment system 2, an advanced treatment system 3, a sludge treatment system 4 and a phosphorus recovery system 5 connected in sequence, the pretreatment System 1 comprises coarse grid 11, fine grid and aerated grit chamber 12 and fine grid tank 13 connected in sequence, and described biological treatment system 2 comprises AO processing unit 21 and secondary sedimentation tank unit 22 connected in sequence, so The advanced treatment system 3 includes a denitrification filter 31, an air flotation tank 32 and a contact disinfection tank 33 connected in sequence; the sludge treatment system 4 includes a sludge thickening tank unit 41, a sludge conditioning tank 42 and sludge Dehydration machine room 43; the phosphorus recovery system 5 includes a phosphorus slag stirring tank 51, a phosphorus slag concen...

Embodiment 2

[0044] Such as figure 1 , the present embodiment provides a sewage treatment method for denitrification and recovery of phosphorus, which includes the following steps:

[0045] S1. The sewage enters the coarse grid 11, the fine grid and the aeration grit chamber 12 and the fine grid tank 13 in order to remove garbage, fine suspended matter and sludge sand particles in the sewage;

[0046] S2. The sewage treated by the fine grid pool 13 is transferred to the water intake channel of the AO treatment unit 21 through the biological pool water inlet main pipe 23, and the sewage is distributed in proportion to the anoxic pools at all levels through the water inlet branch pipe 24, and the sewage Ammonia nitrogen, total nitrogen, and organic matter are removed in the AO treatment unit, and each level of AO unit is equipped with a nitrifying liquid internal reflux system to strengthen the removal of total nitrogen; the muddy water mixture treated by the AO treatment unit 21 enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com