Drawing process of phosphatized steel wire for optical cable reinforcement

A drawing process and phosphating steel wire technology, applied in metal processing equipment, metal material coating process, manufacturing tools and other directions, can solve the problems of reduced lubrication effect, insufficient and comprehensive lubrication of phosphating steel wire, etc., to achieve enhanced lubrication effect, Improve resource utilization and facilitate cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] A drawing process for phosphating steel wire for optical cable reinforcement, comprising the following steps:

[0043] S1. First, take the high-carbon high-quality wire of Shagang as the raw material of phosphating steel wire, and carry out pickling and phosphating treatment on the high-carbon high-quality wire of Shagang;

[0044] S2, then wash the Shagang high-carbon high-quality wire in S1 with industrial soap water to remove the residual impurities after the pickling and phosphating treatment of the Shagang high-carbon high-quality wire;

[0045] S3. Then, the high-carbon high-carbon wire of Shagang in S2 is lubricated by the lubricating device with wire drawing powder, and then lubricated and drawn by the water tank wire drawing machine, so that it is physically drawn to various diameters through the wire drawing die, and the drawn phosphated steel wire.

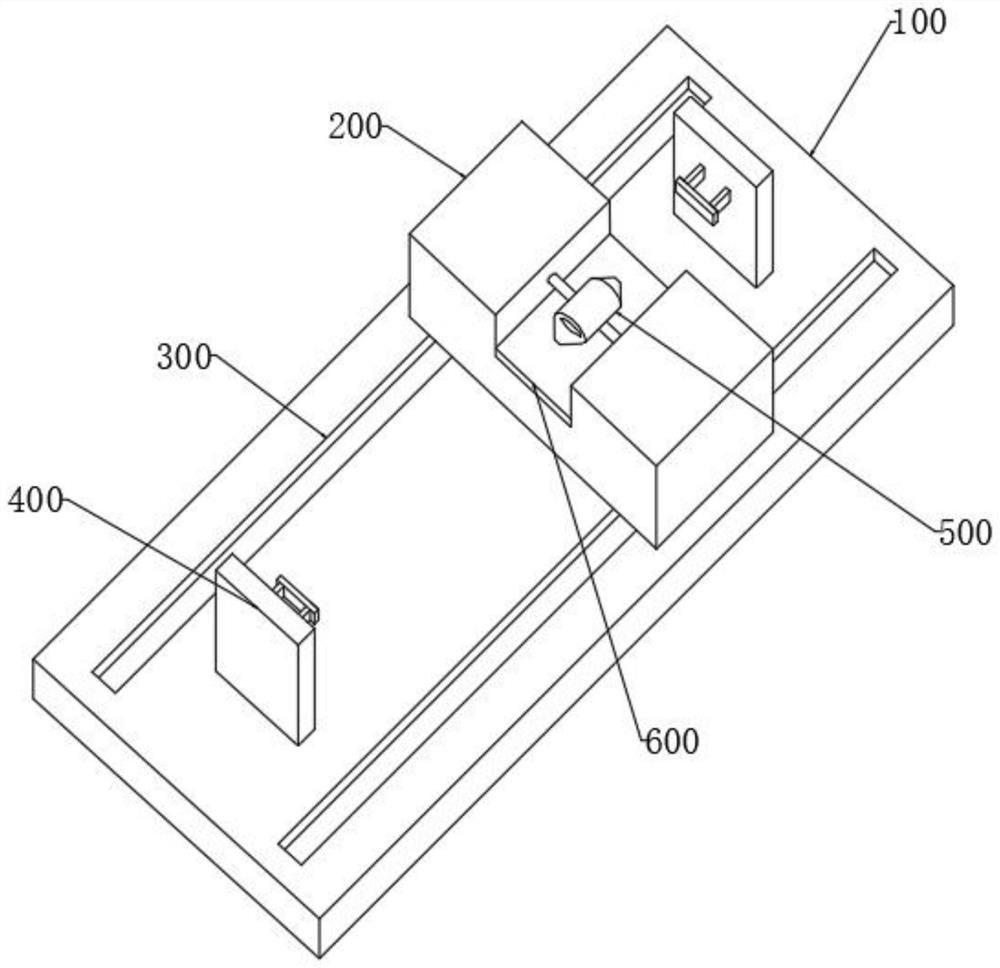

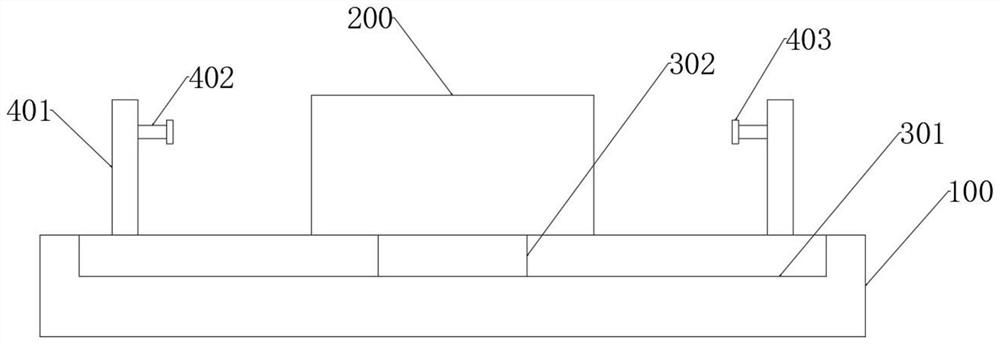

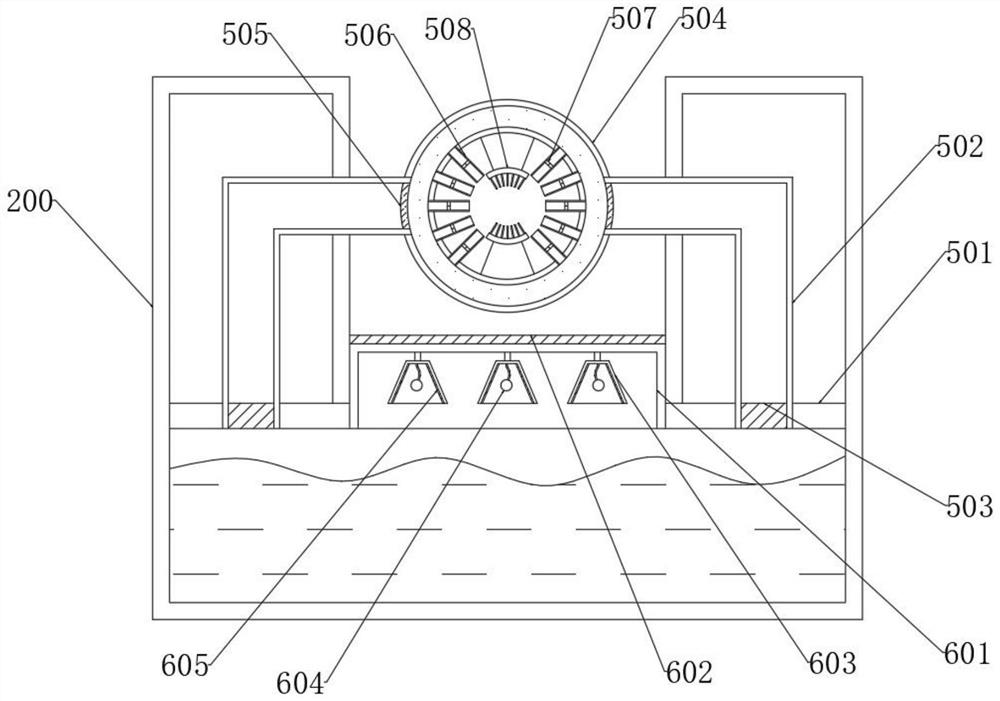

[0046] see Figure 1-6 , the lubricating device in S2 includes an installation base 100, the upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com