Multifunctional metal ore fine ore powder production equipment for metallurgy

A technology for production equipment and metal ore, applied in the field of metallurgical multifunctional metal ore fine ore powder production equipment, can solve problems such as easily damaged equipment, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

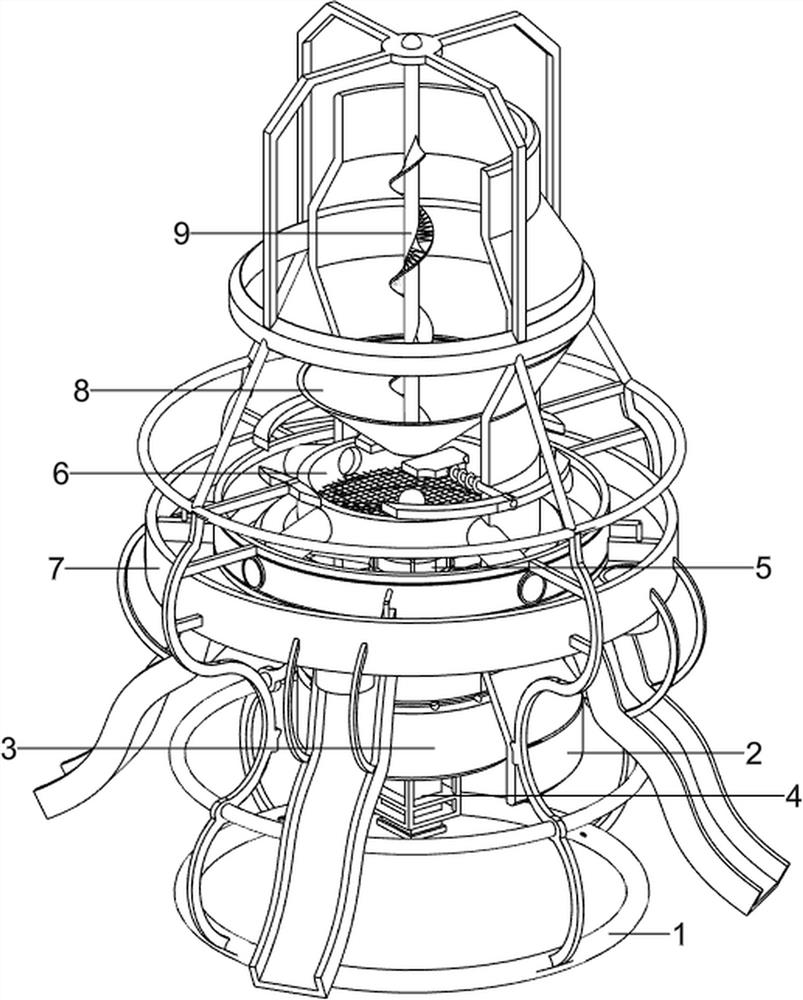

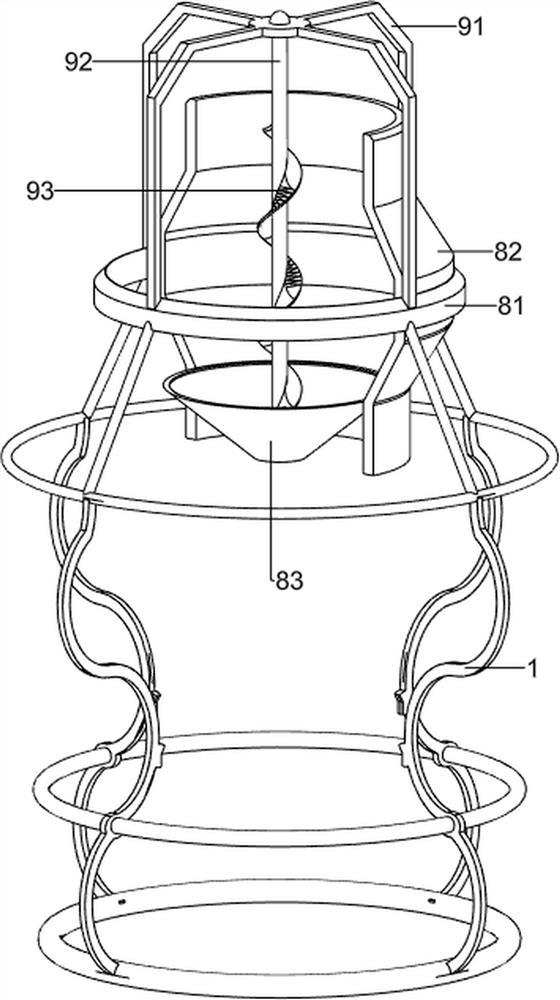

[0069] A metallurgical multifunctional metal ore fine powder production equipment, such as Figure 1-4 As shown, it includes a bracket 1, an installation shell 2, a grinding wheel 3, a grinding mechanism 4 and a pushing mechanism 5. The middle part of the bracket 1 is provided with an installation shell 2, and the upper and lower sides of the installation shell 2 are provided with a grinding wheel 3. The grinding wheel 3 is rotatably connected with the installation shell 2, the bottom of the grinding wheel 3 is provided with a grinding mechanism 4, and the inner side of the top of the installation shell 2 is provided with a pushing mechanism 5.

[0070] When people need to grind metal ore, people can use this metallurgical multifunctional metal ore fine ore production equipment. First, people pour the metal ore into the grinding wheel 3, and then people start the grinding mechanism 4, and the grinding mechanism 4 The operation will drive the pushing mechanism 5 to operate, and...

Embodiment 2

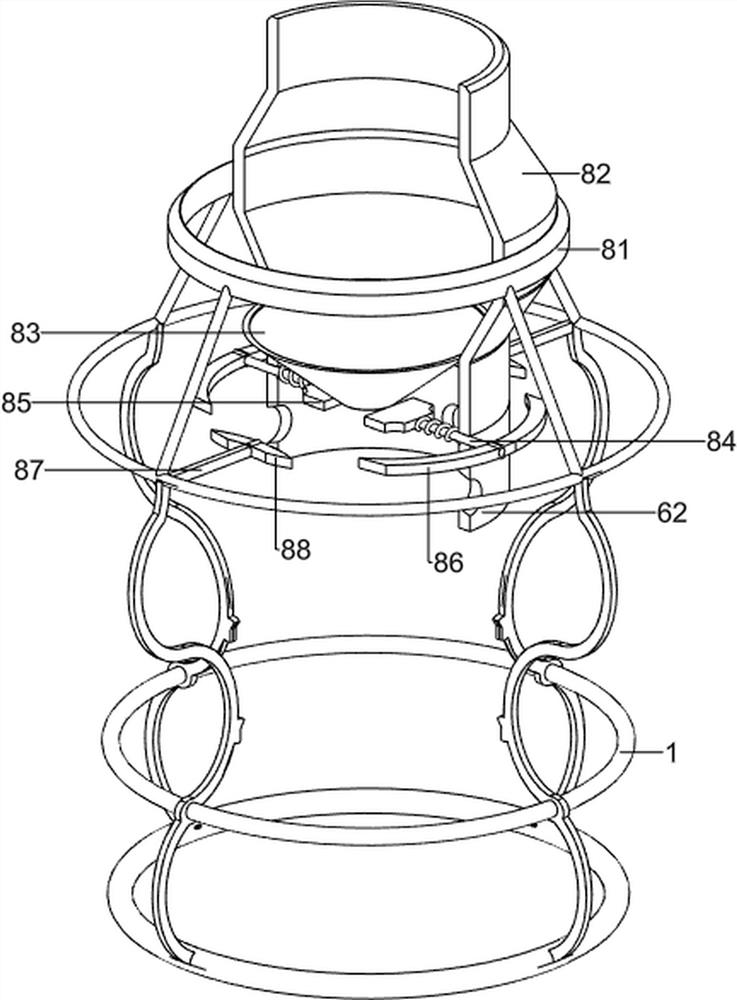

[0076] On the basis of Example 1, such as Figure 5-8 As shown, it also includes a distribution mechanism 6, the distribution mechanism 6 includes a guide sleeve 61, a mounting plate 62, a screen 63 and a material guide pipe 64, the top of the installation shell 2 is provided with a guide sleeve 61, and the top of the second rotating shaft 56 is provided with There is a screen 63, the outside of the screen 63 is provided with a mounting plate 62, the mounting plate 62 is rotationally connected with the guide sleeve 61, and a feed pipe 64 is evenly arranged between the mounting plate 62 and the outer wall of the screen 63, the number of feed pipes 64 For four.

[0077] People can pour metal ore on the screen 63, at this time, the small metal ore falls down for grinding, and the large metal ore stays on the screen 63. When the second rotating shaft 56 rotates, the rotation of the second rotating shaft 56 will drive The screen 63 rotates, thereby driving the mounting plate 62 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com