Automatic plane detection grinding device

A grinding process and plane technology, applied in the direction of grinding driving device, grinding automatic control device, grinding slide plate, etc., can solve the problems of reducing production efficiency, prolonging the time of grinding processing, and grinding of protrusions, etc., to achieve Effects of prolonging service life, preventing damage, and alleviating impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

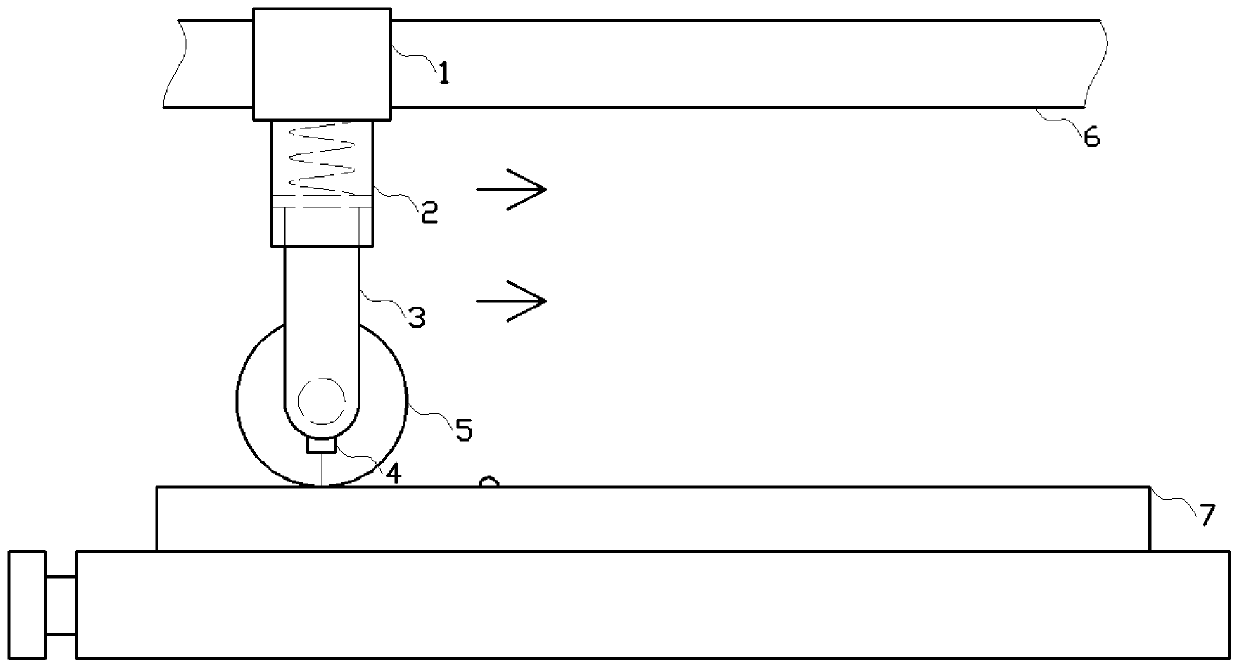

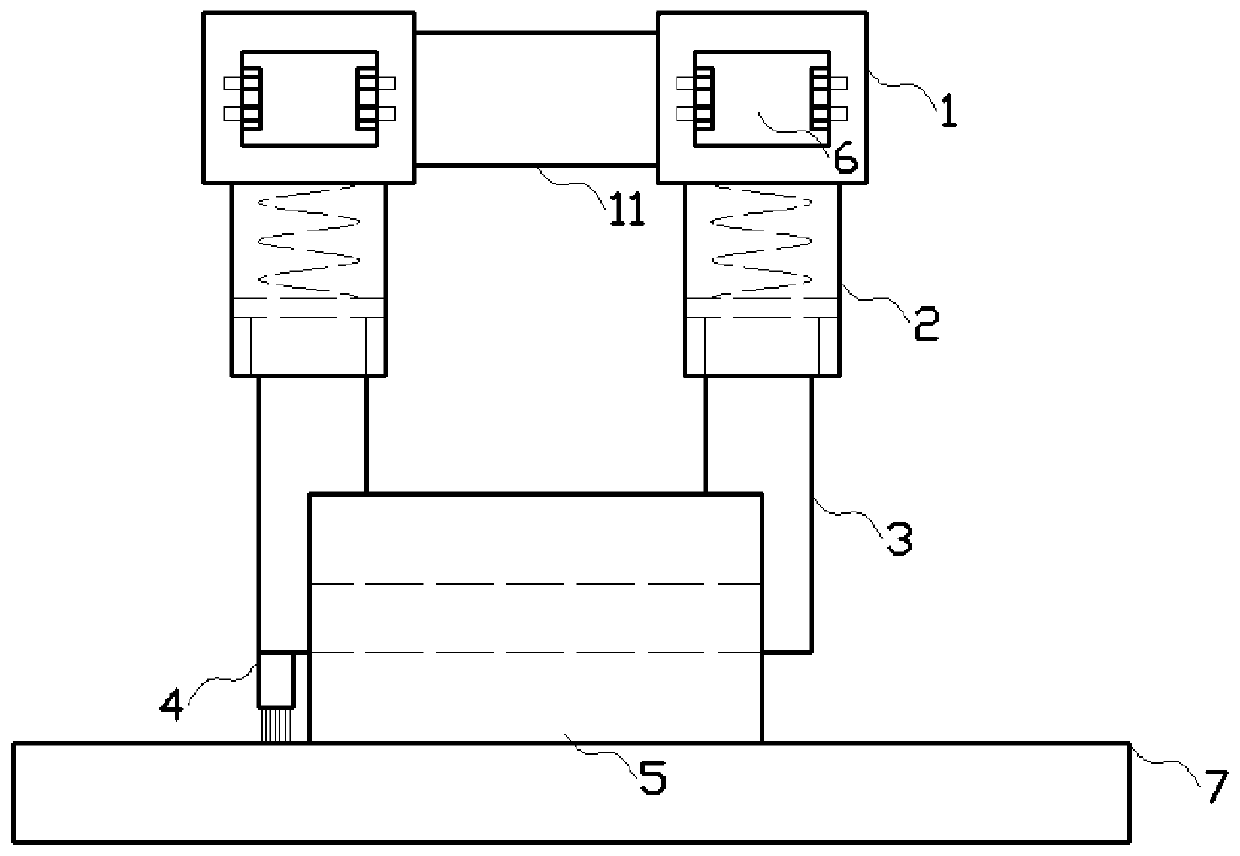

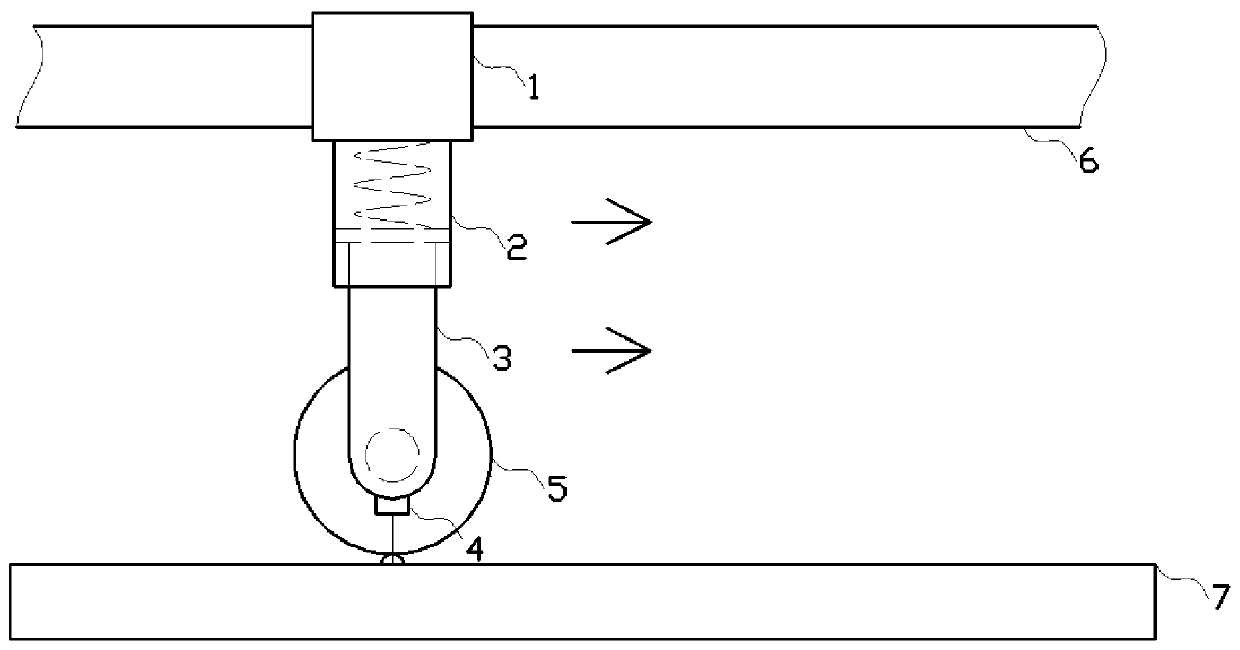

[0014] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown in the embodiment, the automatic plane detection grinding processing device is a kind of grinding tool that can automatically detect and position the plane flatness through the undulating state of the movement on the plane plate, and can automatically position when the uneven part is detected. , a device that triggers automatic reciprocating grinding motion and processes it until it is ground flat, it includes a drive module 1, a connecting rod 2, a telescopic rod 3, a detection module 4 and a grinding piece 5; the drive module 1 includes a shell, and the A sliding groove is provided inside the housing, and the driving module 1 is slidably assembled on the sliding rail 6 through the sliding groove; rollers are arranged in the sliding groove, and the rollers are driven by a driving motor, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com