Efficient reaction kettle for chemical production

A technology for chemical production and reaction kettle, which is applied in the field of high-efficiency reaction kettles for chemical production, can solve the problems of affecting product quality, not taking into account solid raw materials, and insufficient material reaction, so as to facilitate flowability, shorten reaction time, and improve reaction. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

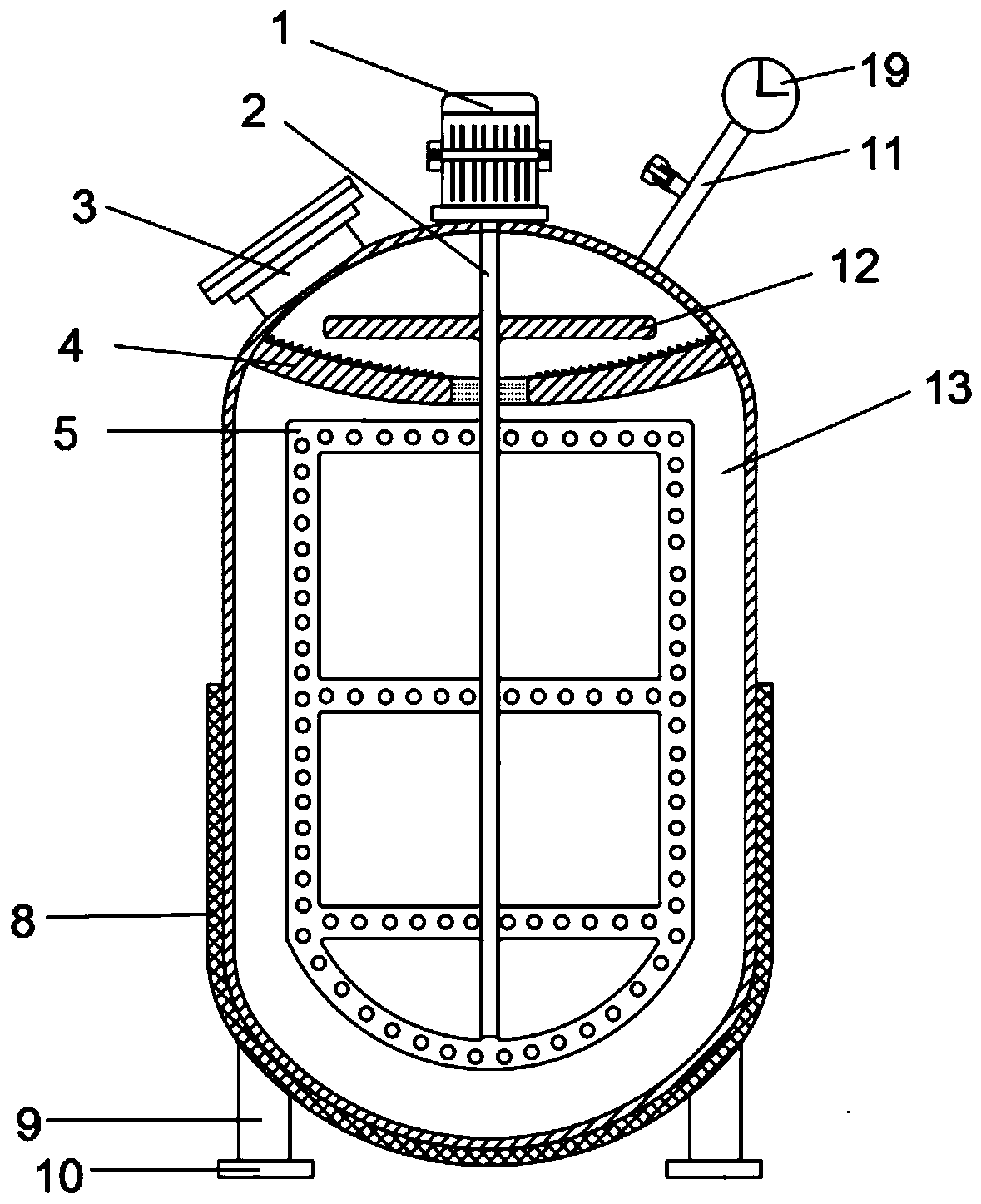

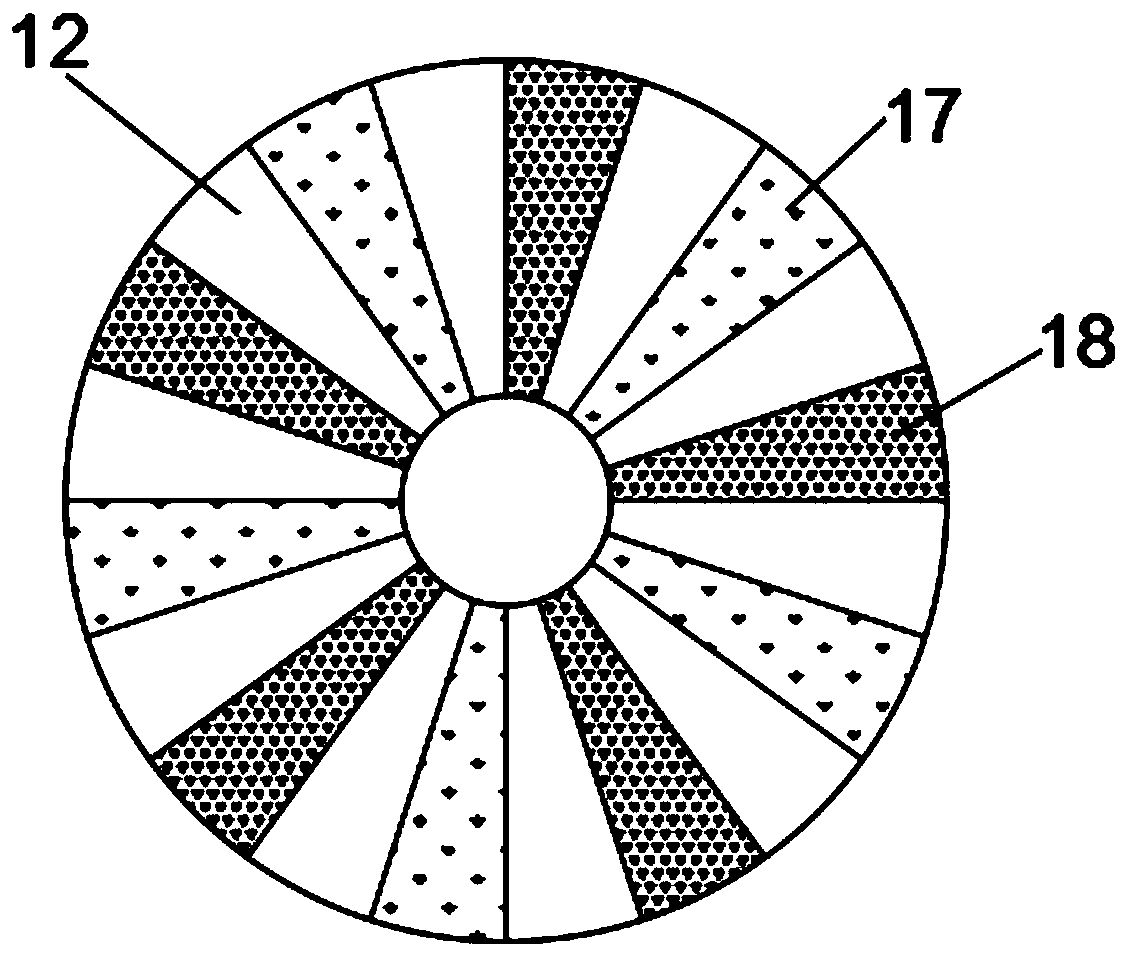

[0026] refer to Figure 1-3 , a high-efficiency reaction kettle for chemical production, including a tank body 13, the top outer wall of the tank body 13 is connected with a motor 1 through screws, the output shaft of the motor 1 is fixed with a rotating shaft 2 through a coupling, and the upper side of the outer wall of the rotating shaft 2 The turntable 12 is connected by a key, the bottom of the outer wall of the turntable 12 is welded with brushes 17 and spikes 18 alternately, the upper side of the inner wall of the tank body 13 is welded with a grinding disc 4, the upper part of the outer wall of the grinding disc 4 is welded with grinding thorns, and the lower side of the outer wall of the rotating shaft 2 The stirring paddle 5 is fixed by screws, and the outer wall of the stirring paddle 5 is evenly opened with flow holes.

[0027] In the present invention, the feed pipe 3 is fixed on the left side of the top outer wall of the tank body 13 by screws, and the inside of t...

Embodiment 2

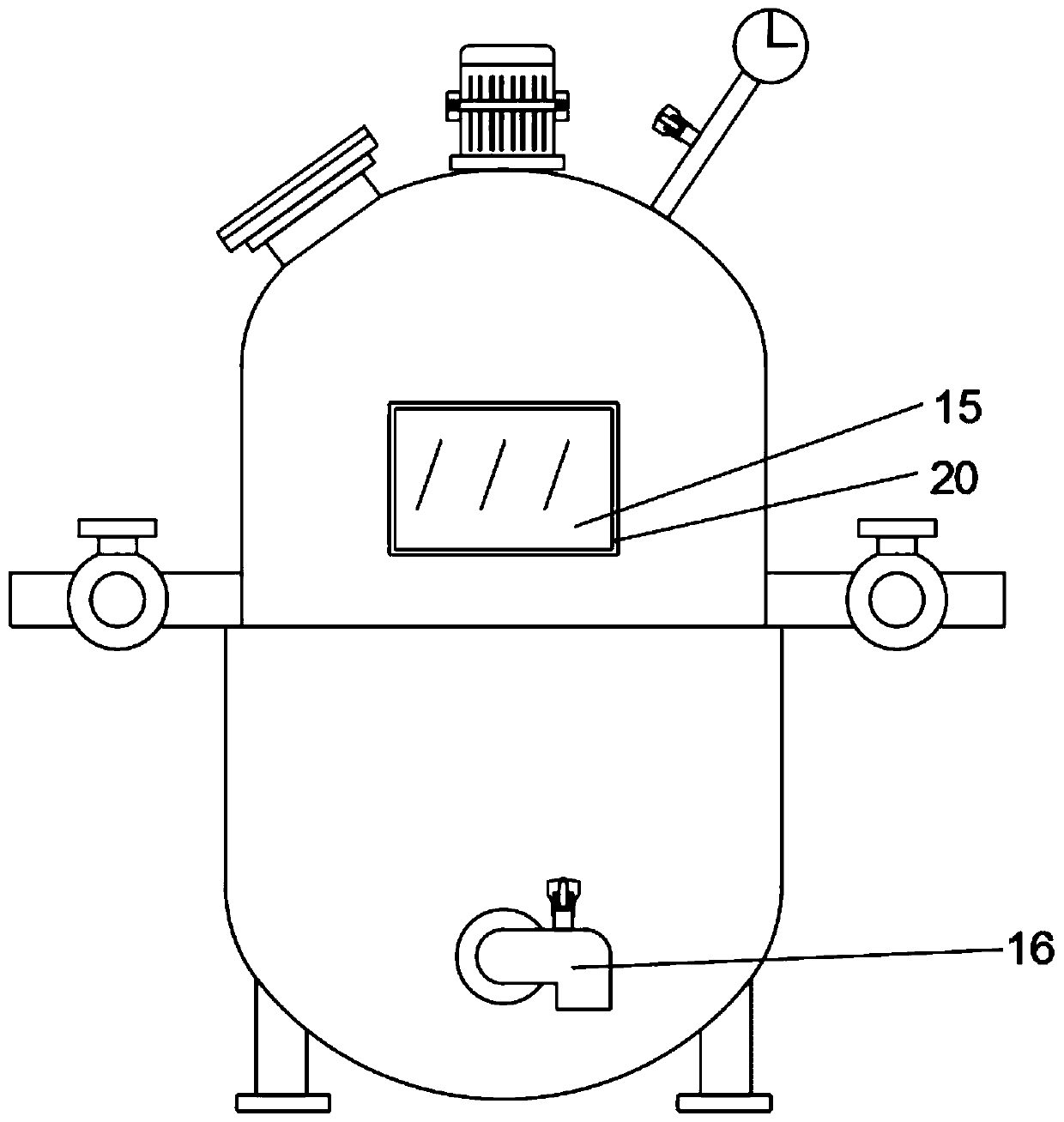

[0034] refer to figure 2 and Figure 4 , a high-efficiency reaction kettle for chemical production, the inner wall of the lower half of the tank body 13 is provided with a heating chamber, the inner wall of the heating chamber is welded with a heating layer 7, and the outer walls of both sides of the tank body 13 are respectively provided with a water inlet pipe 6 and an outlet pipe 14, Moreover, the outer walls of the water inlet pipe 6 and the water outlet pipe 14 are connected with electromagnetic valves through clamps.

[0035] Working principle: When the material enters the lower side of the tank body 13 through the feed hole of the turntable 4 and stirs, the water inlet pipe 6 and the water outlet pipe 14 are opened, and the hot water enters the inner heating layer 7 of the lower side of the tank body 13 from the water inlet pipe 6, and then flows from the Emit in the outlet pipe 14, make the hot water evenly flow in and out, keep the heating uniform when the material ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap