Nickel-iron-based catalyst as well as preparation and application thereof

A nickel-iron-based catalyst technology, applied in the field of electrochemistry, can solve problems such as high price, low reserves, and restricted development, and achieve excellent results, simple synthesis methods, and low overpotential effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

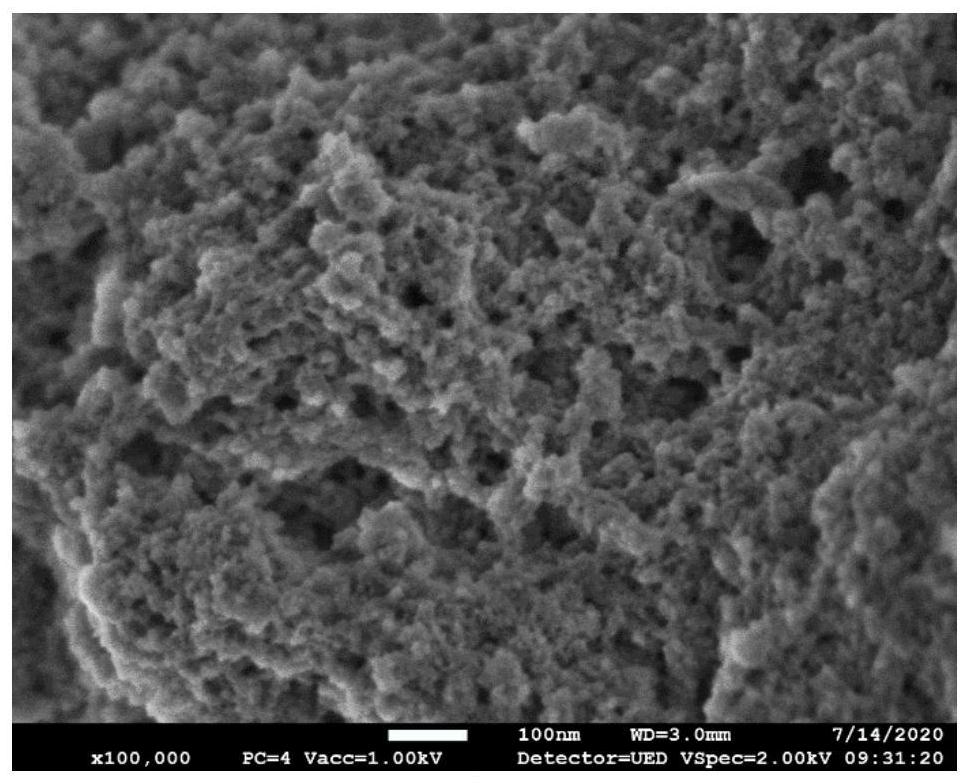

Image

Examples

Embodiment 1

[0049] Example 1, High Performance NIFE Base Power Catalytic Oxygen Catalyst NIFE 0.2 (OOH) 1.2 Preparation and electrical catalytic epoxy test

[0050] 1) Precarrier NIFE 0.2 -FE PBA preparation

[0051] First take 987.8mg K 3 [Fe (CN) 3 ] Soluble in a beaker with 300 ml ultrapure water volume of 500 ml (10moll -1 ), Ultrasound makes it fully dissolved; followed by Ni 3+ (Moor) of nickel ions in metal nickel salt): Fe 3+ (Metal iron salt in iron ion): [FE (CN) 6 ] 3+ (Mole) of Cryanate in Cyanate) = 1: M: (M + 2 / 3) ratio, value m = 0.2, configure NICL 2 · 6h 2 O and FECL 3 · 6h 2 O. Mixed solution, ie 822.8 mg NiCl, respectively 2 · 6h 2 O and 300mg 197.1mg fecl 3 · 6h 2 O Soluble in a 1L beaker in 300ml, while adding the reactant (K 3 [Fe (CN)3 ], NICL 2 · 6h 2 O and FECL 3 · 6h 2 O) 8% of total mass (accounted for NICL 2 · 6h 2 O and FECL 3 · 6h 2 O metal salt mass 15.7%) of the conductive material 161mg (a carbon nanotube having an outer diameter of 10-20 μm, length of 5-15 μm...

Embodiment 2

[0067] Example 2, High Performance NIFE Base Power Catalytic Oxygen Catalyst NIFE 0.25 (OOH) 1.25 Preparation and electrical catalytic epoxy test

[0068] 1) Precarrier NIFE 0.25 -FE PBAS preparation

[0069] First take 987.8mg K 3 [Fe (CN) 3 ] Soluble in a beaker with 300 ml ultrapure water volume of 500 ml (10moll -1 ), Ultrasound makes it fully dissolved; followed by Ni 3+ (Moor) of nickel ions in metal nickel salt): Fe 3+ (Metal iron salt in iron ion): [FE (CN) 6 ] 3+ (Mole) of Cryanate in Cyanate) = 1: M: (M + 2 / 3) ratio, value m = 0.2, configure NICL 2 · 6h 2 O and FECL 3 · 6h 2 O The mixed solution, ie 777.9mg NiCl, respectively. 2 · 6h 2 O and 300mg 221.2mg fecl 3 · 6h 2 O Soluble in a 1L beaker in 300ml, while adding the reactant (K 3 [Fe (CN) 3 ], NICL 2 · 6h 2 O and FECL 3 · 6h 2 O) 8% of total mass (accounted for NICL 2 · 6h 2 O and FECL 3 · 6h 2 The total mass of the total mass of the metal is 159.0mg (the outer diameter of 10-20 μm, the length of 5-15 μm is 5-15 μm) ...

Embodiment 3

[0085] Example 3, High Performance NIFE Base Power Catalytic Oxygen Catalyst NIFE 0.11 (OOH) 1.11 Preparation and electrical catalytic epoxy test

[0086] Example 3 Exploring the precursor NIFE 0.11 -FE PBA synthetic reactant Ni 3+ (Moor) of nickel ions in metal nickel salt): Fe 3+ (Metal iron salt in iron ion): [FE (CN) 6 ] 3+ (Mole) = 1: M: (M + 2 / 3) ratio of C C cyssate is the same as in Example 1, and the remaining steps are the same as in Example 1 (K 3 [Fe (CN) 3 ] The amount is unchanged). The value M = 0.11 is taken in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com