Device and method for synthesizing nano nitride powder by using thermal plasma

A technology of thermal plasma and nitride, which is applied in the field of plasma applications, can solve the problems of expensive alkyl substances, difficulty in controlling powder particle size, unfavorable batch production, etc., and achieve fast reaction speed, fast reaction speed and high production capacity efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

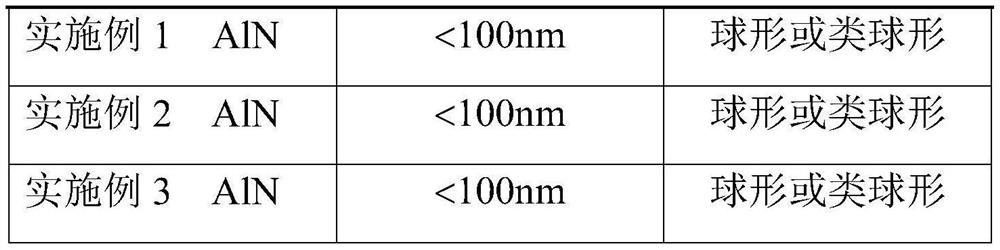

[0033] In this embodiment, nano-aluminum nitride AlN is used as nano-nitride to synthesize nano-aluminum nitride powder, which specifically includes the following steps:

[0034] Step 1. Place metal raw materials

[0035] Put aluminum powder with a particle size between 2-5 μm into the crucible made of aluminum nitride through the metal material inlet of the nitride crucible.

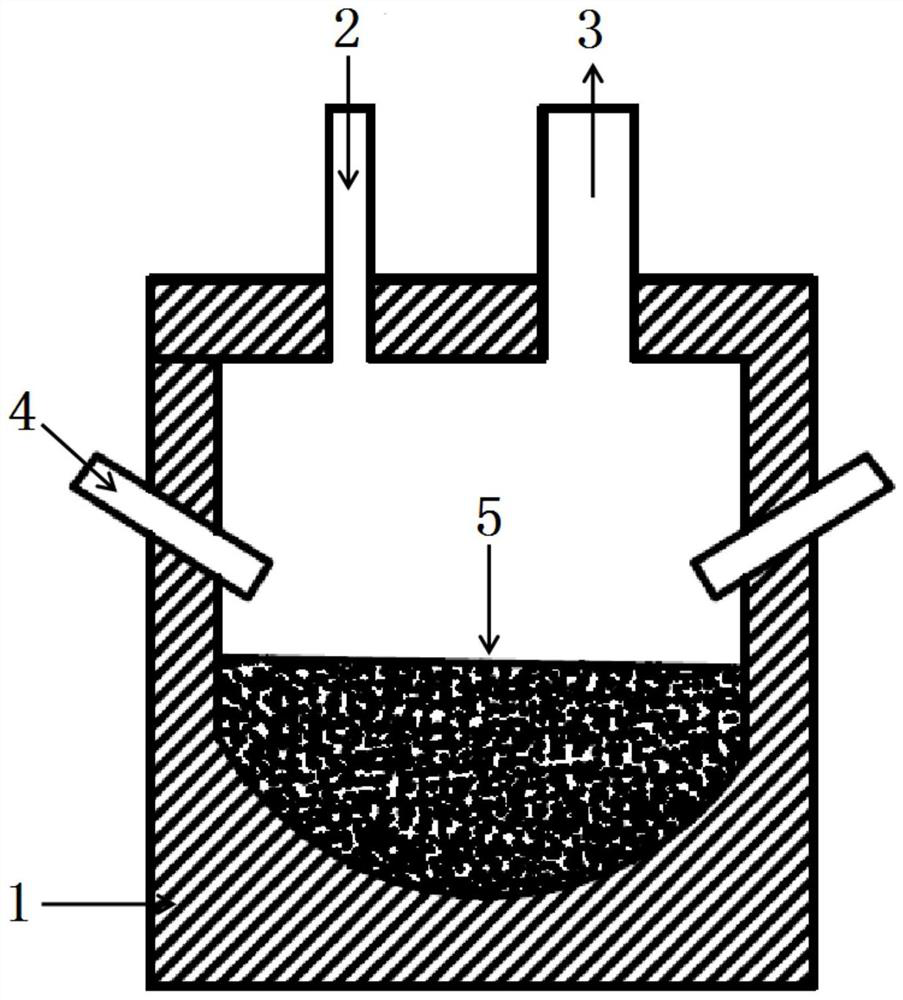

[0036] The structure of the plasma furnace for synthesizing aluminum nitride powder in this embodiment, such as figure 1 As shown, the plasma furnace crucible shown is made of aluminum nitride crucible, and three 100kW DC arc plasma torches are evenly distributed around it.

[0037] Step 2. Vacuumize the inner cavity of the nitride crucible for background replacement

[0038] After the aluminum powder material is put in, close all valves of the plasma synthesis nitriding system and turn on the vacuum pump group to pump the system vacuum to less than 3×10 -3 Pa, until it reaches 2~3×10 -3 Fill N into...

Embodiment 2

[0049] In this embodiment, nano-Si 3 N 4 As nano-nitrides, nano-Si 3 N 4 The synthesis of powder specifically comprises the following steps:

[0050] Step 1. Place metal raw materials

[0051] Silicon powder with a particle size between 2-5 μm is put into the crucible made of silicon nitride through the metal material inlet of the nitride crucible.

[0052] The structure of the plasma furnace for synthesizing silicon nitride powder in this embodiment, such as figure 1 As shown, the plasma furnace crucible shown is made of silicon nitride crucible, and three 100kW DC arc plasma torches are evenly distributed around it.

[0053] Step 2. Vacuumize the inner cavity of the nitride crucible for background replacement

[0054] After the silicon powder material is put in, close all valves of the plasma synthesis nitriding system and turn on the vacuum pump group to pump the system vacuum to less than 3×10 -3 Pa, until it reaches 2~3×10 -3 Fill N into the furnace after Pa 2 To...

Embodiment 3

[0065] In this embodiment, nano-GaN is used as nano-nitride to synthesize nano-GaN powder, which specifically includes the following steps:

[0066] Step 1. Place metal raw materials

[0067] Gallium powder with a particle size between 2-5 μm is put into the crucible made of gallium nitride through the metal material inlet of the nitride crucible.

[0068] The structure of the plasma furnace for synthesizing gallium nitride powder in this embodiment, such as figure 1 As shown, the plasma furnace crucible shown is made of gallium nitride crucible, and three 100kW DC arc plasma torches are evenly distributed around it.

[0069] Step 2. Vacuumize the inner cavity of the nitride crucible for background replacement

[0070] After the gallium powder material is put in, close all valves of the plasma synthesis nitriding system and turn on the vacuum pump group to pump the system vacuum to less than 3×10 -3 Pa, until it reaches 2~3×10 -3 Fill N into the furnace after Pa 2 To atmo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com