Tail gas purification treatment system of cremation machine

A tail gas purification and treatment system technology, which is applied in the direction of combustion product treatment, fire rescue, exhaust gas exhaust device, etc., can solve the problems of harming human health and polluting the environment, and achieve the effect of ensuring physical and mental health, environmental friendliness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

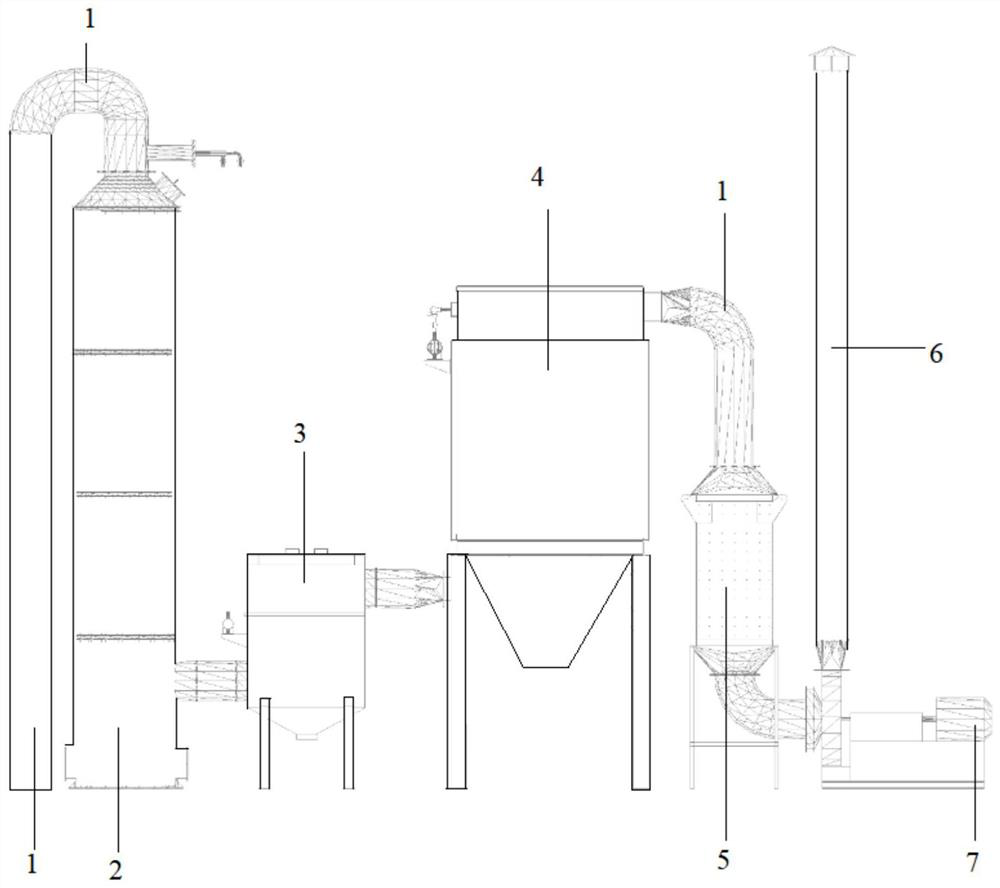

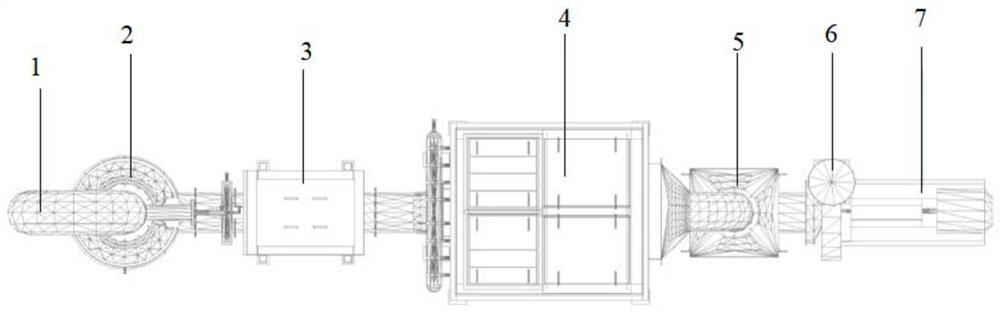

[0028] combine figure 1 , figure 2 Shown is a cremation machine tail gas purification treatment system provided according to a preferred embodiment of the present invention, including: a smoke exhaust pipe 1, a dual-fluid high-efficiency cooling reactor 2 connected in sequence through the smoke exhaust pipe 1, and a spark interception device 3 , pulse bag filter 4, dioxin treatment device 5, chimney 6, and induced draft fan 7. The functions and effects of each component are detailed in the following description:

[0029] First, the high-temperature flue gas generated after the body is cremated by the cremation machine enters the dual-fluid high-efficiency cooling reactor 2 through the exhaust pipe 1, and the sodium hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com