Process for producing 3,5-xylenol under reduced pressure by using organic heat carrier heating technology

A technology of xylenol and industrial xylenol, which is applied in the field of coking, can solve the problems of difficult control of gas heating temperature, insensitive temperature adjustment, and poor fraction separation effect, etc., to achieve convenient operation and maintenance, sensitive and accurate temperature adjustment, and reduce production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

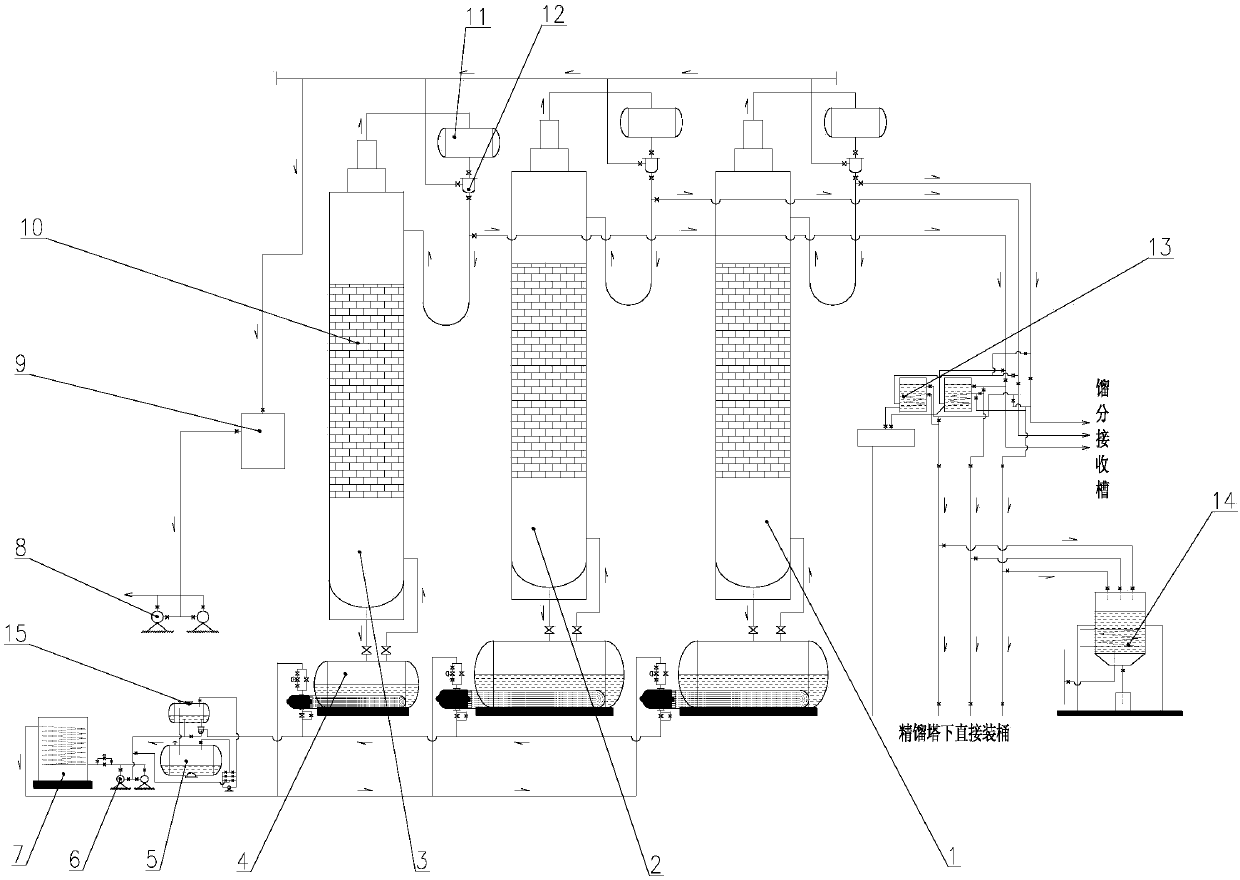

[0041] See figure 1 , a process for producing 3,5-xylenol under reduced pressure with organic heat carrier heating technology. Heat carrier heating technology adopts the production process of negative pressure batch rectification to industrially produce 3,5-xylenol in a single tank, the details are as follows:

[0042] 1) The heat-conducting oil heated by the burner 7 is used as a heat carrier to circulate heat for the distillation kettle 4 .

[0043] Start the burner 7, and the heat transfer oil continues to heat up in the circulation pipeline (the outlet of the thermal oil pump 6 → the burner 7 → the instant heat unit of the still 4 → the oil return main pipe → the inlet of the thermal oil pump 6). The temperature at the top of the tower controls the heating rate.

[0044] 2) Start the vacuum pump 8, adjust the opening of the outlet valve of the vacuum pump 8 to keep the vacuum degree in the rectification tower between 60-90KPa, and the pressure difference between the bott...

Embodiment 2

[0052] See figure 1 , a process for producing 3,5-xylenol under reduced pressure using organic heat carrier heating technology. The industrial production of 3,5-xylenol in kettles is as follows:

[0053] 1) The heat-conducting oil heated by the burner 7 is used as a heat carrier to circulate heat for the distillation kettle 4 .

[0054] 2) Start the vacuum pump 8, adjust the opening of the outlet valve of the vacuum pump 8 to keep the vacuum degree in the rectification tower between 60-90KPa, and the pressure difference between the bottom and the top of the tower is 6-10KPa.

[0055] 3) Negative pressure rectification of two kettles to process industrial xylenol at the same time. After the raw materials in the still 4 are heated, the mixed vaporized fraction enters the rectification tower from the still 4 through the riser, and a part of the top gas phase fraction is liquefied and combined with the tower The bottom gas phase fraction conducts heat and mass transfer on the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com