Safe flame-retardant polyimide diaphragm and preparation method thereof

A polyimide and diaphragm technology, applied in the field of safe flame-retardant polyimide diaphragm and its preparation, can solve the problems of flammability, lithium-ion battery thermal runaway, smoke and fire, and achieve the effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

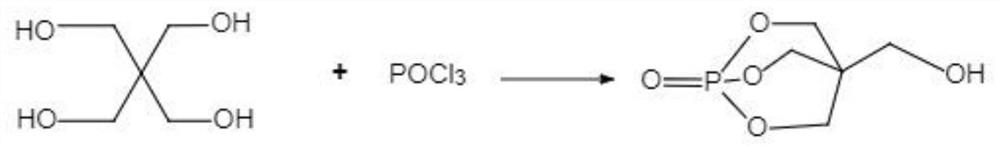

[0046] (1) Preparation of phosphorus-containing pentaerythritol flame retardant:

[0047] (1.1) Add 300mL of solvent dioxane and 65g of pentaerythritol to a 500mL three-necked flask successively, under the protection of nitrogen atmosphere, heat up and stir to 83°C, add 43mL of phosphorus oxychloride dropwise, heat up to 100°C, condense and reflux for 16h ; Filter, wash once with dioxane, wash twice with n-hexane, and dry to obtain intermediate product 1;

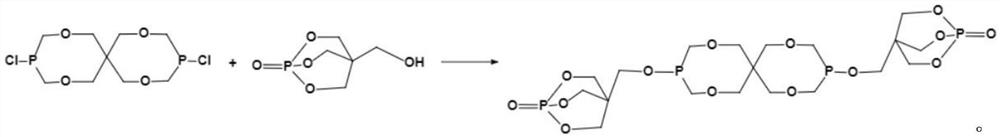

[0048] (1.2) Add 50mL o-dichlorobenzene, 25g pentaerythritol, 35mL phosphorus trichloride, and 0.15mL catalyst triethylamine successively in a 250mL three-necked flask. 100°C, kept at a constant temperature for 1 hour to obtain intermediate product 2;

[0049] Add 50g of intermediate product 1 directly, and then add 20g of sodium hydroxide to neutralize the HCl produced by the reaction to promote the positive direction of the reaction. Stop heating after 3 hours of reaction; filter, wash with dimethyl sulfoxide for 3 times...

Embodiment 2

[0057] (1) Preparation of phosphorus-containing pentaerythritol flame retardant:

[0058] (1.1) Add 300mL of solvent dioxane and 65g of pentaerythritol to a 500mL three-necked flask successively, under the protection of nitrogen atmosphere, heat up and stir to 80°C, add 57.5g of phosphorus oxychloride dropwise, heat up to 95°C, condense and reflux 15.5h; filter, wash once with dioxane, wash twice with n-hexane, and dry to obtain intermediate product 1;

[0059] (1.2) Add 50mL of o-dichlorobenzene, 25g of pentaerythritol, 57.5g of phosphorus trichloride, and 36.2g of catalyst triethylamine into a 250mL three-necked flask in sequence. Under the protection of nitrogen atmosphere, heat in an oil bath, and raise the temperature of the system within 3 hours to 95°C and kept at constant temperature for 1 hour to obtain intermediate product 2;

[0060] Directly add 50g of intermediate product 1, then add 20g of sodium hydroxide to neutralize the HCl produced by the reaction to promot...

Embodiment 3

[0068] (1) Preparation of phosphorus-containing pentaerythritol flame retardant:

[0069] (1.1) Add 300mL of solvent dioxane and 65g of pentaerythritol to a 500mL three-necked flask successively, under the protection of nitrogen atmosphere, heat up and stir to 85°C, add 70.8g of phosphorus oxychloride dropwise, heat up to 105°C, condense and reflux 16.5h; filter, wash once with dioxane, wash twice with n-hexane, and dry to obtain intermediate product 1;

[0070] (1.2) Add 50mL of o-dichlorobenzene, 25g of pentaerythritol, 57.7g of phosphorus trichloride, and 36.6g of catalyst triethylamine into a 250mL three-necked flask in sequence. Under the protection of nitrogen atmosphere, heat the oil bath, and raise the temperature of the system within 3 hours to 105°C, and kept at constant temperature for 1 hour to obtain intermediate product 2;

[0071] Directly add 50g of intermediate product 1, then add 20g of sodium hydroxide to neutralize the HCl produced by the reaction, promote...

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com