P-type doping method of oxide semiconductor

A technology of oxide semiconductors and semiconductors, which is applied in the manufacture of semiconductors/solid-state devices, electrical components, circuits, etc., can solve problems such as doping, achieve uniform doping distribution, prevent sublimation, and increase the activation rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the examples, the following examples are explanations of the present invention and the present invention is not limited to the following examples.

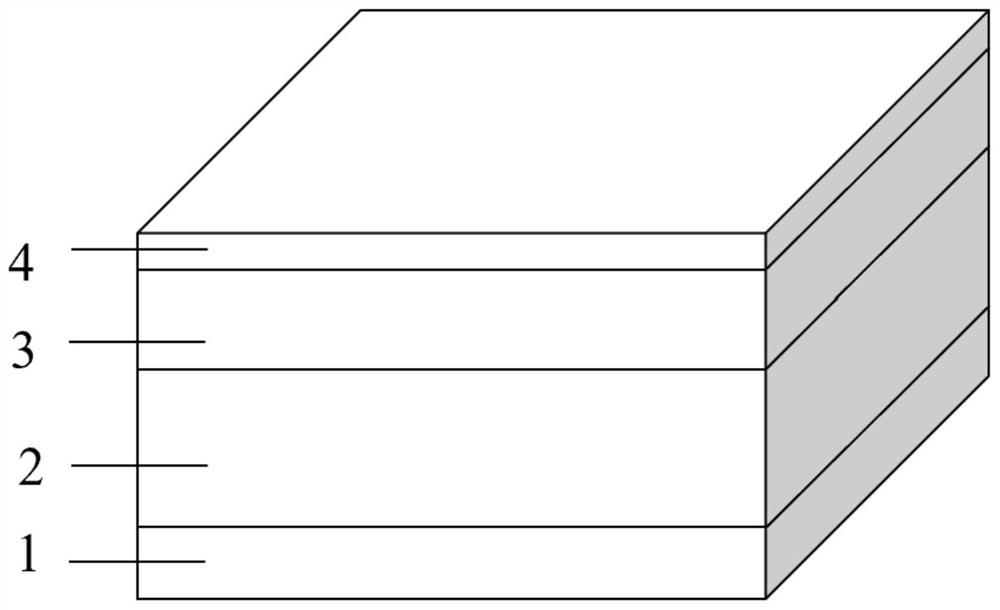

[0024] Such as figure 1 As shown, a P-doped structure includes a substrate layer 1, an epitaxial layer 2, an injection layer 3 and an annealing protection layer 4. The substrate layer 1 and the epitaxial layer 2 can be replaced with different oxide semiconductor substrates and grown epitaxially. The implanted layer 3 is implanted with N element, and its implant dose should be two orders of magnitude or more of the doping concentration of the epitaxial layer. In one embodiment of the present invention, the concentration of the epitaxial layer for the used substrate is 1×10 16 cm -3 , the concentration of the injected N element should be at least two orders of magnitude greater, namely 1×10 18 cm -3 above. And its depth can also be changed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com