Water-based graphene zinc powder anticorrosive paint and preparation method thereof

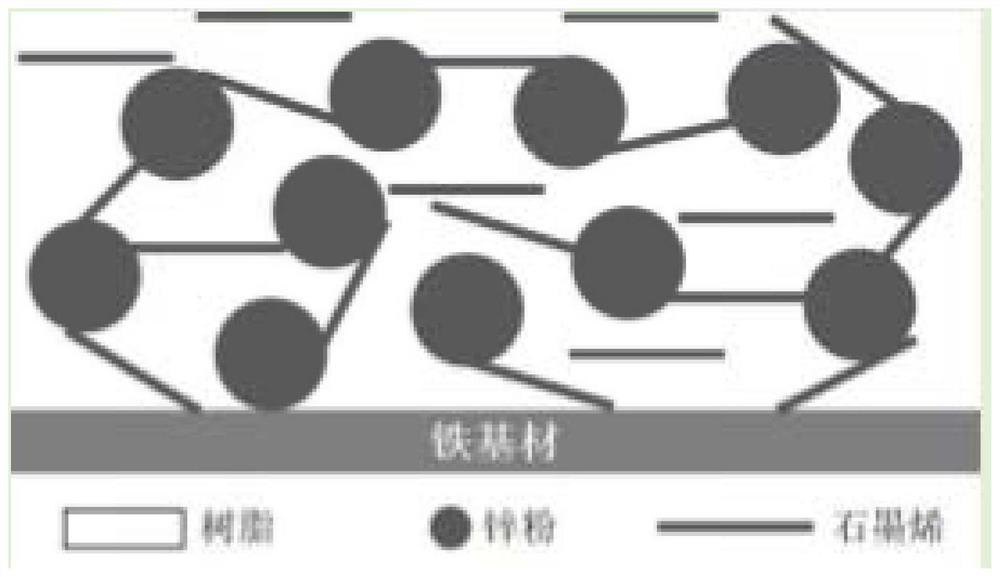

A water-based graphene and anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of water resistance, salt spray resistance time gap, easy to form defects, corrosion resistance performance gap and other problems, and achieve low Outstanding effects of VOC emission, delayed penetration, and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] According to the ratio, weigh 76.7g of resin emulsion, 0.3g of defoamer, 0.3g of wetting agent, 0.2g of anti-flash rust agent, and stir for 10 minutes; weigh 0.5g of thickener, add it to 12g of water, and stir to form a uniform paste After the mixture was formed, it was added to the above slurry and continued to stir for 20 minutes; 10 g of graphene dispersion liquid was weighed, added to the above slurry and stirred for 20 minutes, filtered to obtain component A.

[0070] Above-mentioned, resin emulsion is the epoxy resin emulsion of E20 system, and solid content is 52%, and epoxy equivalent is 500 (commercially available product, from Guangdong Tongde); Defoamer is organosilicon defoamer (commercially available product, from AFCONA), the wetting agent is polyether modified siloxane (commercially available product, from AFCONA), the anti-flash rust agent is effectively divided into 5% sodium nitrite aqueous solution, the thickener is 49% to 53% non-volatile % of associ...

Embodiment 2

[0076] According to the ratio, weigh 76.7g of resin emulsion, 0.3g of defoamer, 0.3g of wetting agent, 0.2g of anti-flash rust agent, and stir for 10 minutes; weigh 0.5g of thickener, add it to 2g of water, and stir to form a uniform paste After the mixture was formed, it was added to the above slurry and continued to stir for 20 minutes; 20 g of graphene dispersion liquid was weighed, added to the above slurry and stirred for 20 minutes, filtered to obtain component A.

[0077] Above-mentioned, resin emulsion is the epoxy resin emulsion of E20 system, and solid content is 52%, and epoxy equivalent is 500 (commercially available product, from Guangdong Tongde); Defoamer is organosilicon defoamer (commercially available product, from AFCONA), the wetting agent is polyether modified siloxane (commercially available product, from AFCONA), the anti-flash rust agent is effectively divided into 5% sodium nitrite aqueous solution, the thickener is 49% to 53% non-volatile % of associa...

Embodiment 3

[0082] According to the ratio, weigh 76.7g of resin emulsion, 0.3g of defoamer, 0.3g of wetting agent, 0.2g of anti-flash rust agent, and stir for 10 minutes; weigh 0.5g of thickener, add it to 2g of water, and stir to form a uniform paste After the mixture was formed, it was added to the above slurry and continued to stir for 20 minutes; 20 g of graphene dispersion liquid was weighed, added to the above slurry and stirred for 20 minutes, filtered to obtain component A.

[0083] Above-mentioned, resin emulsion is the epoxy resin emulsion of E20 system, and solid content is 52%, and epoxy equivalent is 500 (commercially available product, from Guangdong Tongde); Defoamer is organosilicon defoamer (commercially available product, from AFCONA), the wetting agent is polyether modified siloxane (commercially available product, from AFCONA), the anti-flash rust agent is effectively divided into 5% sodium nitrite aqueous solution, the thickener is 49% to 53% non-volatile % of associa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com