Colored reinforced polypropylene composite material as well as preparation method and application thereof

A technology of composite materials and polypropylene, applied in the field of polypropylene, can solve the problems of product mechanical performance decline, mechanical performance decline, strength decline, etc., and achieve the effect of reducing frictional strength, good mechanical performance, and weakening the destructive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

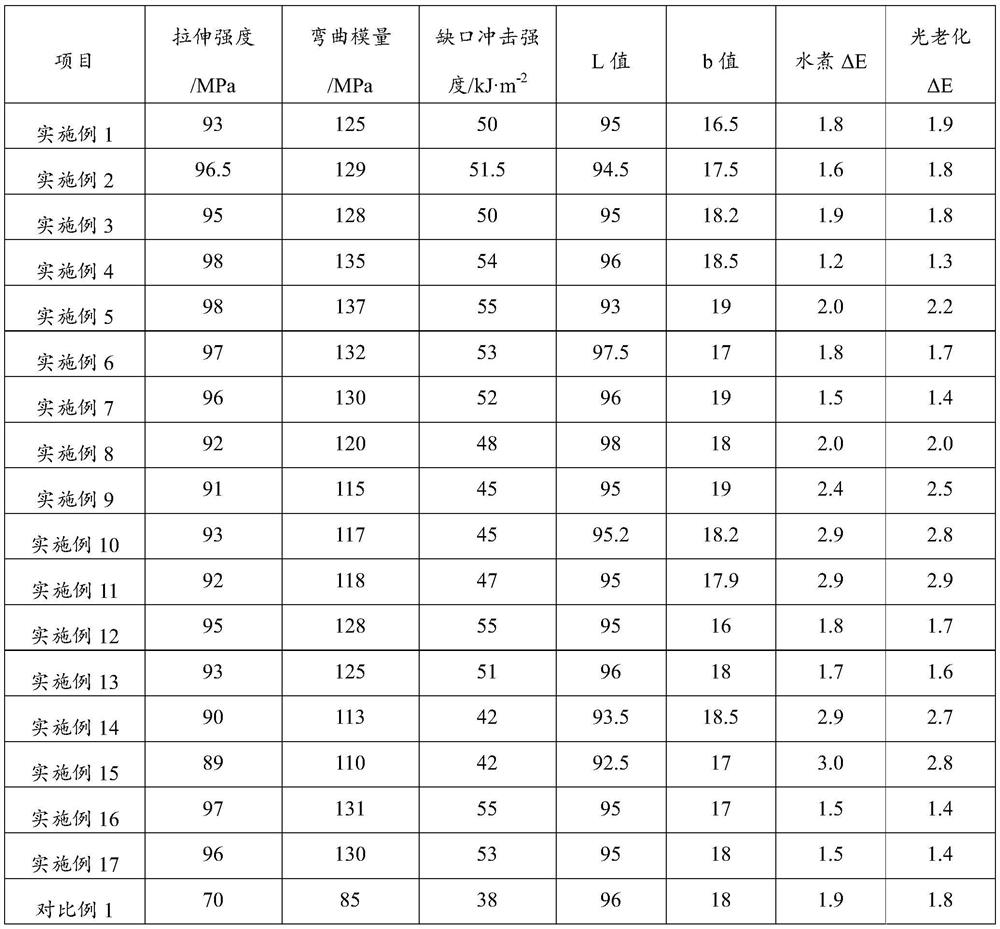

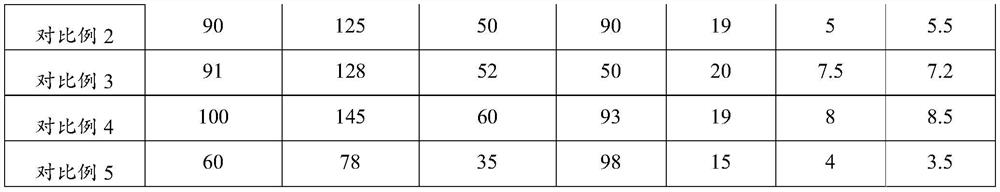

Examples

Embodiment 1~8

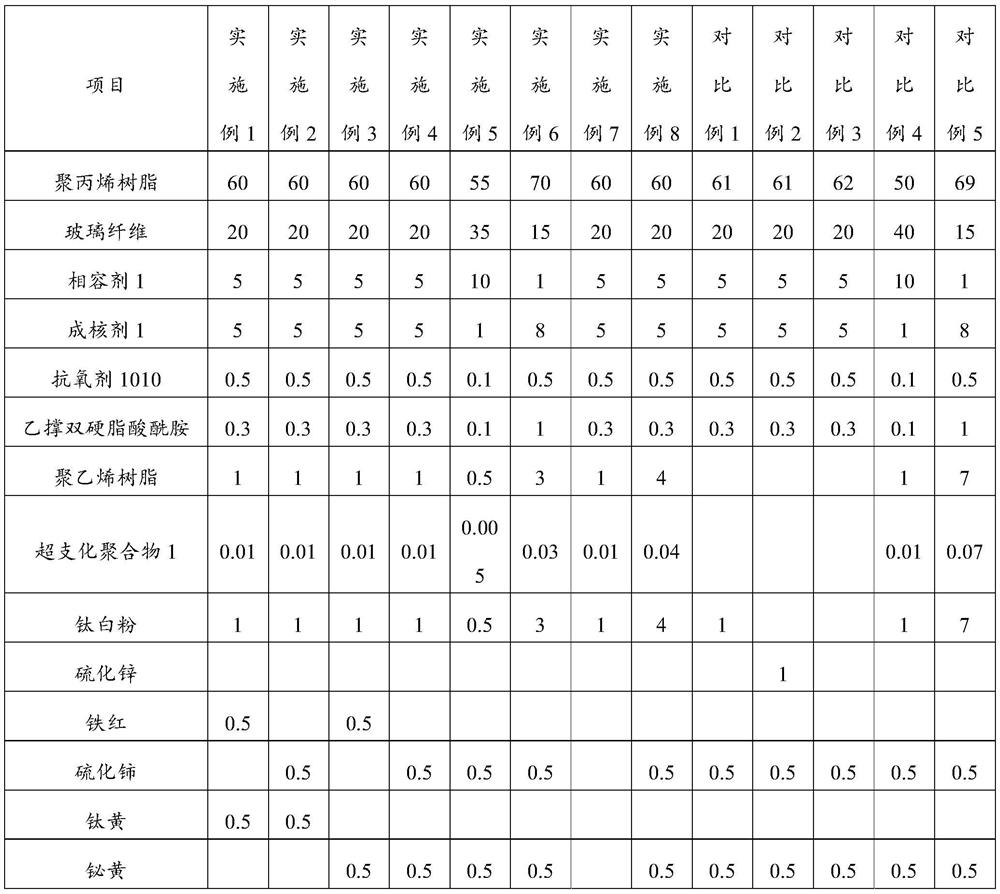

[0039]Examples 1-8 are examples of the colored reinforced polypropylene composite material of the present invention. The formulations of Examples 1-8 are shown in Table 1, and the preparation method is as follows:

[0040] (1) Mix titanium dioxide, hyperbranched polymer 1, and polyethylene resin evenly, and extrude and granulate through an internal mixer to obtain a premix;

[0041] (2) Mix the other components except glass fiber and premix evenly, add them to the main feeding port of the screw extruder, then add glass fiber and premixing materials from the side feeding port, melt blend and extrude Pelletizing and cooling to obtain the colored reinforced polypropylene composite material. The aspect ratio of the extruder is 48:1, the temperature of the extruder is set at 100°C in the T1 zone, 190°C in the T2-T5 zone, and 210°C in the T6-T12 zone, and the speed is 400r / min. The length of the middle tie bar through the water is 1m.

Embodiment 9

[0047] An embodiment of the colored reinforced polypropylene composite material of the present invention, the difference between the colored reinforced polypropylene composite material described in this embodiment and Example 4 is that the compatibilizers selected are different, and the compatible agent selected in this embodiment The agent is compatibilizer 2.

Embodiment 10

[0049] An embodiment of the colored reinforced polypropylene composite material of the present invention, the difference between the colored reinforced polypropylene composite material described in this embodiment and Example 4 is that the nucleating agent selected is different, and the nucleating agent selected in this embodiment The agent is nucleating agent 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com