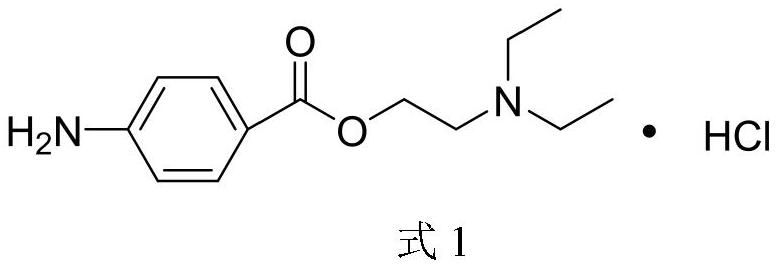

Preparation method of procaine

A technology of procaine and nitrocaine, which is applied in the field of preparation of procaine by aqueous phase hydrogenation of nitrocaine, can solve complex operation procedures, low yield, low procaine yield, etc. problem, to achieve the effect of improving catalytic activity, high product yield and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh H 2 PdCl 4 Solution 5ml (which contains the quality of Pd 0.05g), RuCl 3 Solution 2ml (the quality of which contains Ru 0.005g). Add 1g of activated carbon and 10ml of deionized water into the beaker, mix well, add dropwise 2g of 5wt% ammonium oxalate solution, and stir for 5h at 60°C (stirring rate 200 rpm); then add the above two metal ion-containing solutions dropwise at the same time, Stir at 60°C for 12h (stirring rate 200 rpm). Weigh 1.8gNa 2 CO 3 and 0.1 g of sodium borohydride were dissolved in 10 ml of water, and slowly added dropwise to the catalyst solution to make the pH reach 10, then stirred for 1 h (stirring rate 200 rpm), and ultrasonicated for 1 h (ultrasonic power 100 w). Heated in a water bath at 60°C to evaporate the moisture of the catalyst to dryness. After the water was evaporated to dryness, the catalyst was transferred to a vacuum drying oven and dried in vacuum at 60°C for 8 hours to obtain a 5%Pd-0.5%Ru / C catalyst.

[0031] Add 250...

Embodiment 2

[0035] Weigh H 2 PdCl 4 Solution 2ml (the mass containing Pd 0.01g), RuCl 3 Solution 2ml (containing 0.01g of Ru mass). Add 1g of activated carbon and 10ml of deionized water in a beaker, mix well, add dropwise 1g of 10wt% ammonium oxalate solution, and stir for 2h at 80°C (stirring rate 200 rpm); then add the above two metal ion-containing solutions dropwise at the same time, Stir at 80°C for 12h (stirring rate 200 rpm). Weigh 1.8gNa 2 CO 3 , 0.1g of sodium borohydride was dissolved in 10ml of water, and slowly added dropwise to the catalyst solution to make the pH reach 10, then stirred for 1h (stirring rate 200 rpm), and ultrasonicated for 1h (ultrasonic power 100w). Heated in a water bath at 80°C to evaporate the water in the catalyst to dryness. After the water was evaporated to dryness, the catalyst was transferred to a vacuum drying oven and dried in vacuum at 110°C for 4 hours to obtain a 1%Pd-1%Ru / C catalyst.

[0036]Add 250ml of xylene, 44g of p-nitrobenzoic ac...

Embodiment 3

[0038] Weigh H 2 PdCl 4 Solution 5ml (which contains the quality of Pd 0.05g), RuCl 3 Solution 4ml (the mass containing Ru is 0.02g), add 1g activated carbon and 10ml deionized water to the beaker, mix well, add dropwise 0.5g 10wt% ammonium oxalate solution, stir at 60°C for 2h (stirring speed 200 rpm) ; Then add the above two metal ion-containing solutions dropwise at the same time, and stir at 60°C for 12h (stirring rate 200 rpm). Weigh 1.8gNa 2 CO 3 , 0.1g of sodium borohydride was dissolved in 10mL of water, and slowly added dropwise to the catalyst solution to make the pH reach 10, then stirred for 1h (stirring rate 200 rpm), and ultrasonicated for 1h (ultrasonic power 100w). Heated in a water bath at 60°C to evaporate the moisture of the catalyst to dryness. After the moisture was evaporated to dryness, the catalyst was transferred to a vacuum drying oven and dried in vacuum at 80°C for 10 hours to obtain a 5%Pd-2%Ru / C catalyst.

[0039] Add 250ml of xylene, 44g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com