Welding equipment and welding method

A technology of welding equipment and welding parts, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of poor welding consistency, unstable welding quality, increased equipment and labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0042] As a kind of metal layered composite material, titanium-steel composite plate has broad application prospects. Titanium-steel composite panels combine the advantages of titanium and steel and have been widely used. Among them, titanium alloy has excellent corrosion resistance to various oxidizing acids, various salts and alkalis, especially the pitting corrosion resistance of chloride ions and good mechanical properties. Titanium and its alloys are ideal structures in petrochemical, aerospace and other fields. Material. However, titanium alloys are expensive and difficult to process and shape, which limits their wide application. Low-carbon steel and low-alloy steel have the characteristics of high strength, good welding performance, good processing technology, and low price; but their corrosion resistance is poor, including stainless steel's poor resistance to chloride ion corrosion, which cannot meet certain special requirements. Industry requirements for corrosion ...

Embodiment 3

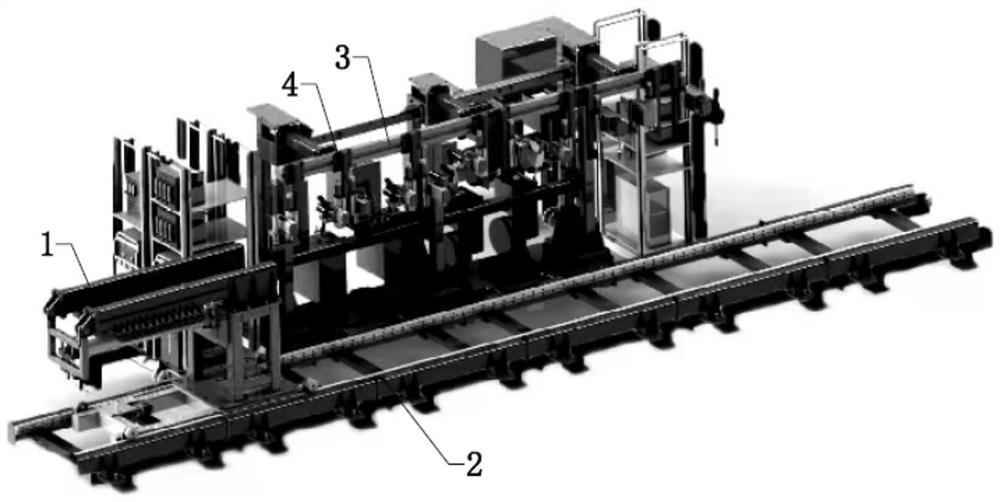

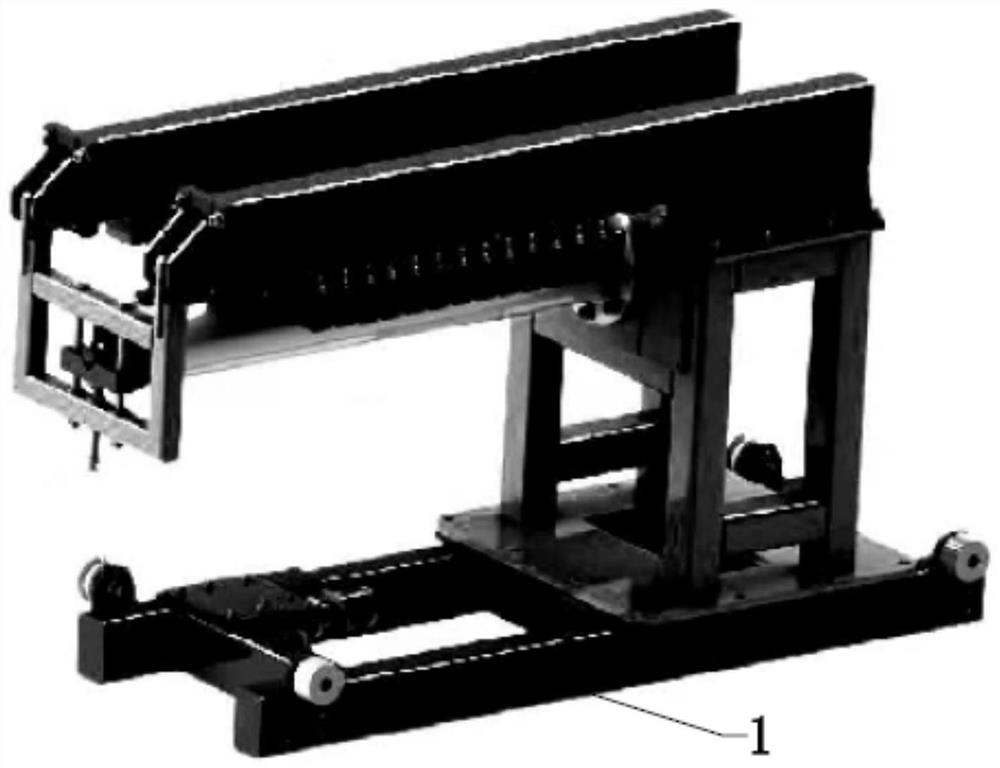

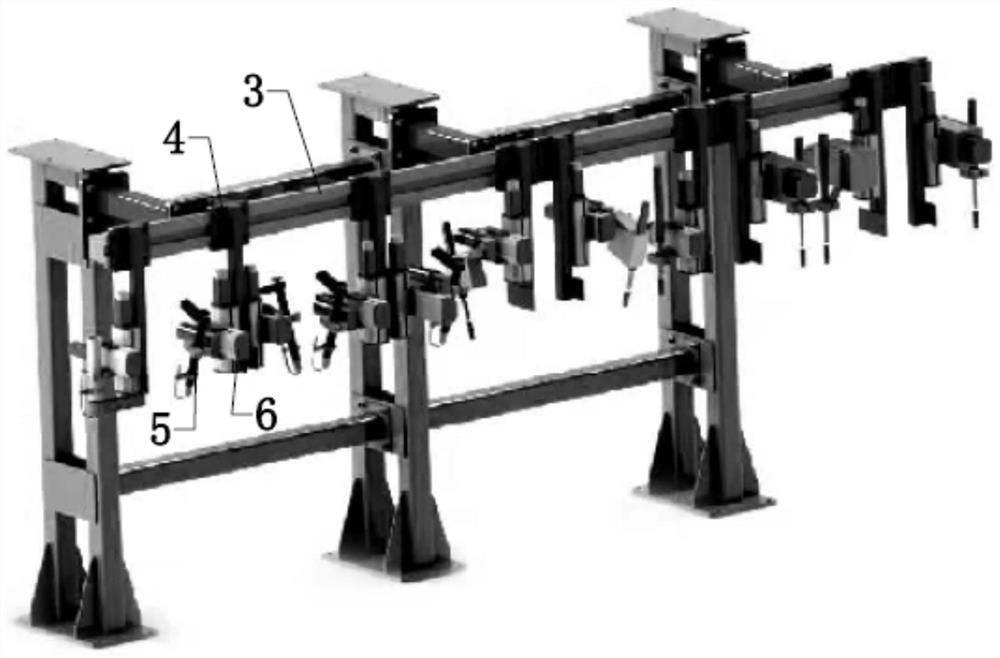

[0063] see figure 1 Shown:

[0064] A welding device includes a tooling trolley 1, a guide part 2, a main frame 3 and a welding suspension 4. Wherein the welding suspension 4 is arranged on the main frame 3, and the welding suspension 4 is provided with at least 3 groups, and the welding suspension 4 is provided with a mounting part 5 for installing and fixing the welding torch, and the welding suspension 4 is arranged in a linear distribution; the tooling trolley 1 It is used to place the parts to be welded, and it is arranged under the welding suspension 4;

[0065] In this embodiment, this equipment is suitable for welding titanium-steel clad plates, and the following will be described based on this application.

[0066] It should be noted that the mounting part 5 is used to install the welding torch of the welding system, and, in this embodiment, this equipment is suitable for the workpiece to be processed whose welding groove is linearly arranged, so the guide part 2 gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com