Device and method for recovering and reusing sulfur dioxide in flue gas

A sulfur dioxide and reuse technology, applied in the field of flue gas desulfurization, can solve problems such as equipment corrosion and secondary pollution of flue gas desulfurization technology, and achieve the effect of low cost, high industrial practical value, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

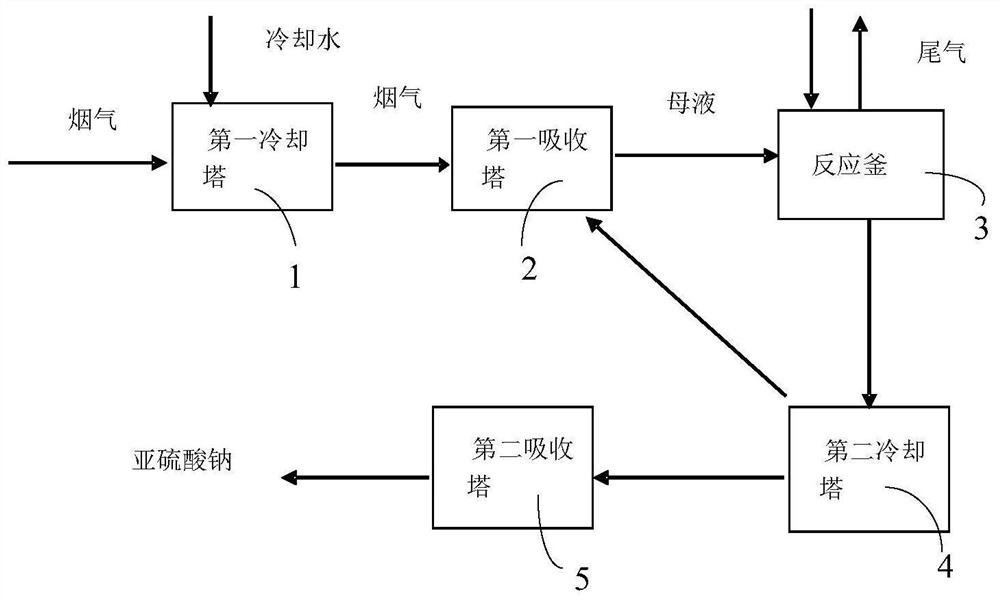

Image

Examples

Embodiment 1

[0056] S1, cooling the flue gas to 60°C;

[0057] S2, passing the cooled flue gas into a supersaturated sodium dihydrogen phosphate solution with a concentration of 110g / L for full absorption to obtain mother liquor and residual gas;

[0058] S3, adding 0.5mol / L ethylenediaminetetraacetic acid to the obtained mother liquor and the remaining gas to react to obtain a reaction solution;

[0059] S4, cooling the reaction solution to 25°C, depositing ethylenediaminetetraacetic acid solids and producing gas;

[0060] S5, passing the precipitated ethylenediaminetetraacetic acid solid into the supersaturated sodium dihydrogen phosphate solution in the step S120, and passing the SO produced in the step S140 2 The gas is passed into solid sodium carbonate to obtain sodium sulfite product.

Embodiment 2

[0062] S1, cooling the flue gas to 80°C;

[0063] S2, passing the cooled flue gas into a supersaturated sodium dihydrogen phosphate solution with a concentration of 180g / L for full absorption to obtain mother liquor and residual gas;

[0064] S3, adding 0.5mol / L ethylenediaminetetraacetic acid to the obtained mother liquor and the remaining gas to react to obtain a reaction solution;

[0065] S4, cooling the reaction solution to 25°C, depositing ethylenediaminetetraacetic acid solids and producing gas;

[0066] S5, passing the precipitated ethylenediaminetetraacetic acid solid into the supersaturated sodium dihydrogen phosphate solution in the step S120, and passing the SO produced in the step S140 2 The gas is passed into solid sodium carbonate to obtain sodium sulfite product.

Embodiment 3

[0068] S1, cooling the flue gas to 100°C;

[0069] S2, passing the cooled flue gas into a supersaturated sodium dihydrogen phosphate solution with a concentration of 240g / L for full absorption to obtain mother liquor and residual gas;

[0070] S3, adding 0.5mol / L ethylenediaminetetraacetic acid to the obtained mother liquor and the remaining gas to react to obtain a reaction solution;

[0071] S4, cooling the reaction solution to 25°C, depositing ethylenediaminetetraacetic acid solids and producing gas;

[0072] S5, passing the precipitated ethylenediaminetetraacetic acid solid into the supersaturated sodium dihydrogen phosphate solution in the step S120, and passing the SO produced in the step S140 2 The gas is passed into solid sodium carbonate to obtain sodium sulfite product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com