Sintered neodymium-iron-boron magnet with high toughness and manufacturing method thereof

A manufacturing method, NdFeB technology, applied in the direction of magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the attached drawings are only for reference and illustration, and are not intended to limit the present invention.

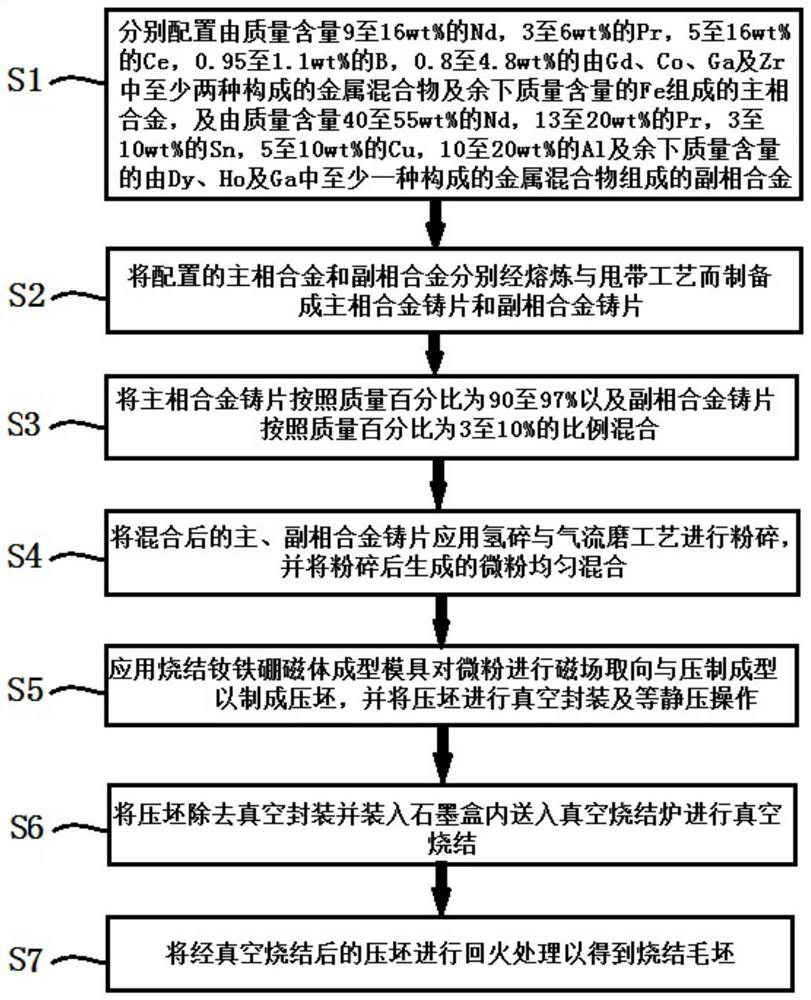

[0028] Such as figure 1 Shown is the flowchart of the manufacturing method of the sintered NdFeB magnet with high toughness of the present invention, and the steps of the manufacturing method include:

[0029]Configuring the main and secondary phase alloy step S1: configuring the main phase alloy, the main phase alloy includes: Nd with a mass content of 9 to 16 wt%, Pr with a mass content of 3 to 6 wt%, and Ce with a mass content of 5 to 16 wt%, B with a mass content of 0.95 to 1.1 wt%, a metal mixture composed of at least two of Gd, Co, Ga, and Zr with a mass content of 0.8 to 4.8 wt%, and the remaining mass content of Fe; a secondary phase alloy, a secondary phase The alloy contains: Nd with a mass content of 40 to 55 wt%, Pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com