Preparation method of silicon/nickel-cobalt-iron photo-anode

A nickel-cobalt-iron and photoanode technology, which is applied in the direction of electrodes, electrolytic components, energy input, etc., can solve the problems of difficult to prepare large-area films, affect film formation, and slow deposition rate, and achieve rapid large-scale preparation and accelerate hydrogen production. The generation, protective corrosion passivation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] A method for preparing a silicon / nickel-cobalt-iron photoanode, comprising the following steps:

[0048] S1. Dissolve nickel sulfate, cobalt sulfate, ferrous sulfate, boric acid and surfactant in deionized water, purging and stirring, and wait until completely dissolved to obtain an electrodeposition solution;

[0049] S2. Immerse the packaged silicon photoanode in the electrodeposition solution configured in step S1, and conduct electrodeposition under the constant current mode of the electrochemical workstation (and the deposition voltage does not reach the reduction potential of each metal ion), to obtain the target product silicon / Nickel-cobalt-iron photoanode.

[0050] Specifically, the specific process of the step S1 is: A mol NiSO 4 , B mol CoSO 4 , C mol FeSO 4 Dissolve in 100mL deionized water to get NiSO 4 、CoSO 4 , FeSO 4 A mixed solution of deionized water, A+B+C=0.01mol (A: 0.002~0.009mol; B: 0.0005~0.004mol; C: 0.0005~0.004mol), was purged and stirr...

Embodiment 1

[0065] 1) 0.002mol NiSO 4 , 0.004mol CoSO 4 , 0.004mol FeSO 4 Dissolve in 100mL deionized water to get NiSO 4 、CoSO 4 , FeSO 4 deionized water mixed solution, nitrogen or argon purging and stirring for 10 minutes;

[0066] 2) Put the sealed silicon photoanode (working electrode), silver / silver chloride electrode (reference electrode) and platinum electrode (counter electrode) into the deionized water mixed solution 3cm below the liquid surface;

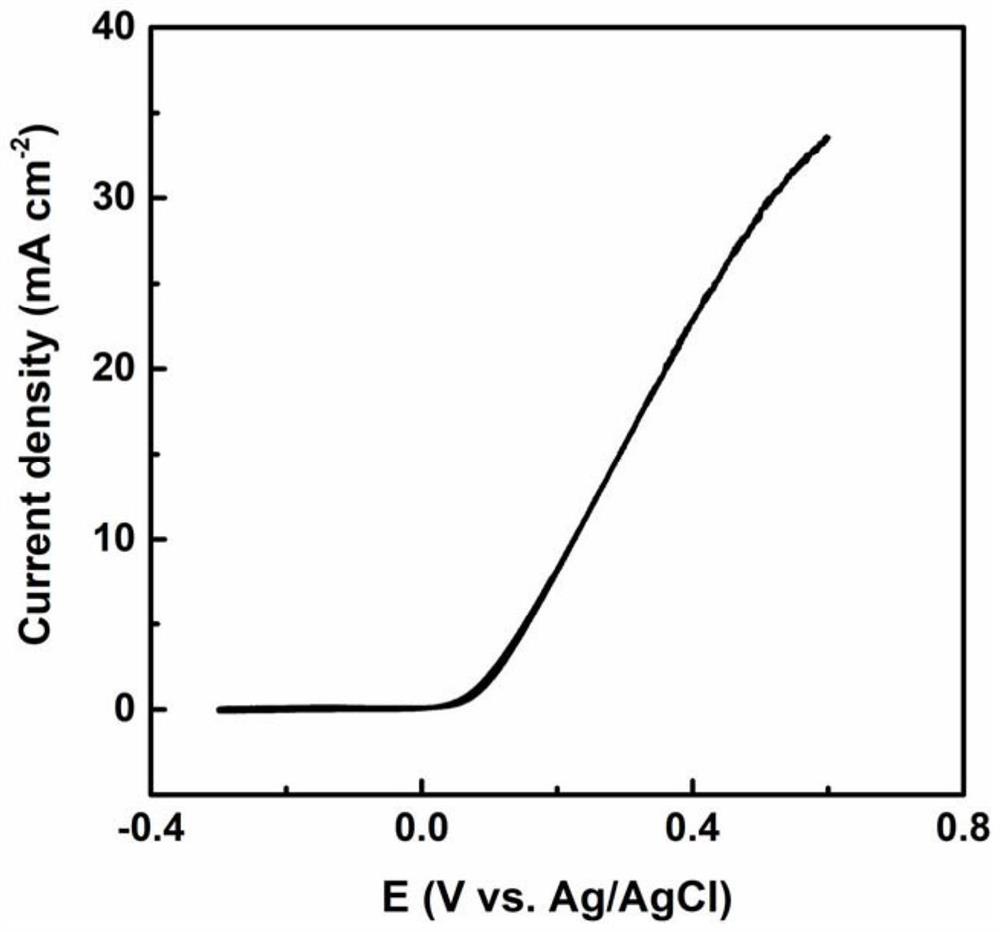

[0067] 3) When performing electrodeposition, set the electrochemical workstation to constant current mode, and the current density is 1mA cm -2 , the deposition time is 1000s, and the deposition temperature is 20°C. After electrodeposition, the silicon / nickel-cobalt-iron photoanode was rinsed with deionized water for 30 seconds to obtain the target product. Electrochemical deposition of silicon / nickel-cobalt-iron photoanodes figure 1 As shown, the cyclic voltammogram of the prepared silicon / nickel-cobalt-iron photoanode is as ...

Embodiment 2

[0069] 1) 0.005mol NiSO 4 , 0.0025mol CoSO 4 , 0.0025mol FeSO 4 Dissolve in 100mL deionized water to get NiSO 4 、CoSO 4 , FeSO 4 deionized water mixed solution, nitrogen or argon purging and stirring for 10 minutes;

[0070] 2) Put the sealed silicon photoanode (working electrode), silver / silver chloride electrode (reference electrode) and platinum electrode (counter electrode) into the deionized water mixed solution 3cm below the liquid surface;

[0071] 3) When performing electrodeposition, set the electrochemical workstation to constant current mode, and the current density is 1mA cm -2 , the deposition time is 1000s, and the deposition temperature is 20°C. After electrodeposition, the silicon / nickel-cobalt-iron photoanode was rinsed with deionized water for 30 seconds to obtain the target product. Electrochemical deposition of silicon / nickel-cobalt-iron photoanodes image 3 As shown, the cyclic voltammogram of the prepared silicon / nickel-cobalt-iron photoanode is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com