Novel zinc alloy wire for electric arc spraying and preparation method of coating

A technology of arc spraying and zinc alloy, which is applied in metal material coating process, coating, molten spraying, etc., can solve the problems of difficult alloy thermal spraying process and easy wire breakage, and achieve the effect of solving thermal spraying process problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

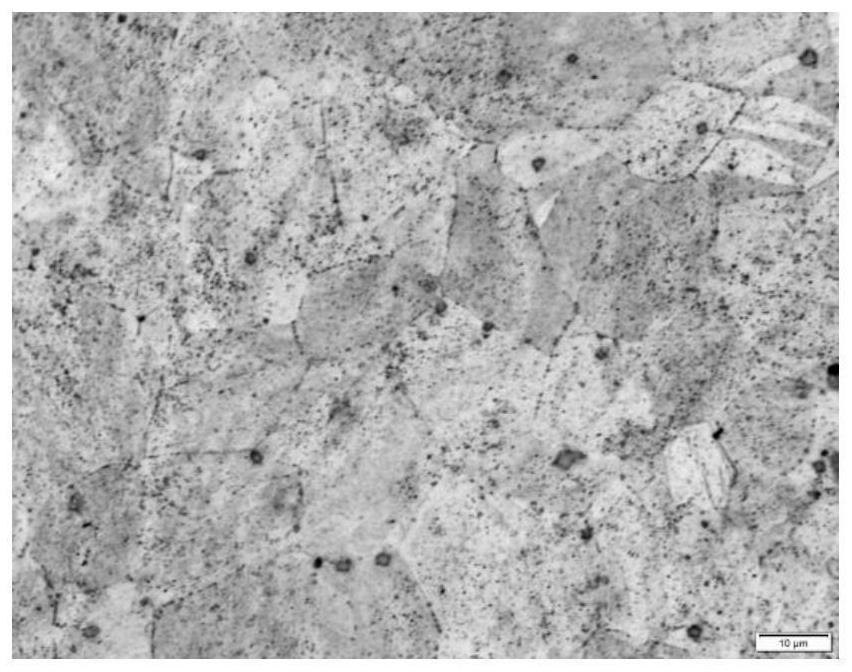

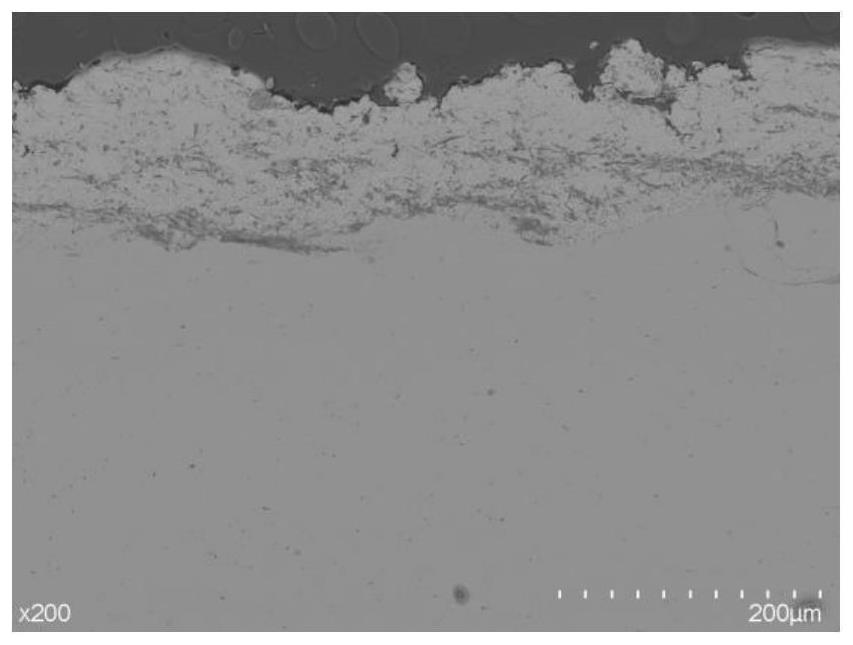

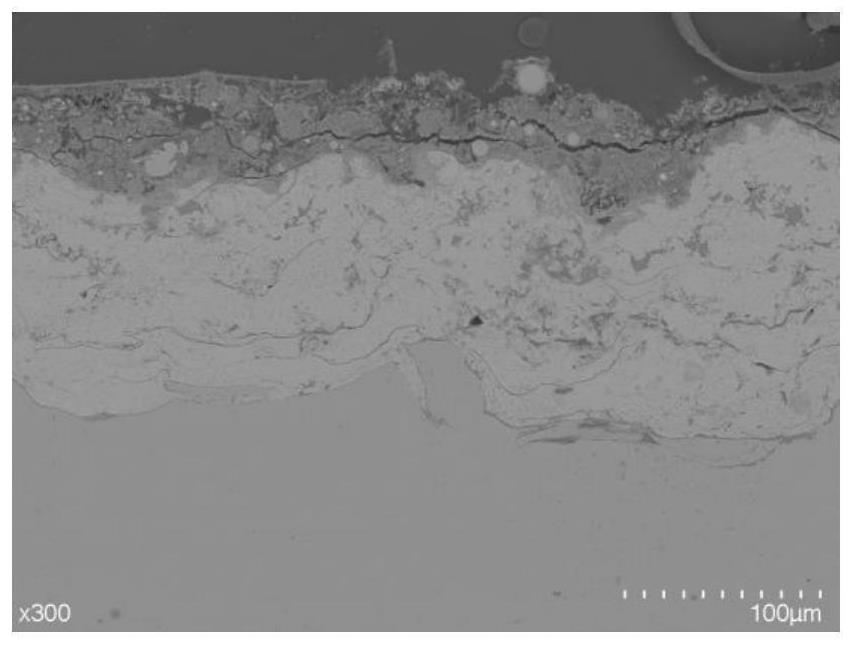

Image

Examples

Embodiment 1

[0026] A preparation method for a novel zinc alloy wire material and coating for electric arc spraying, comprising the following steps:

[0027] (1) Put the custom-made zinc-copper-titanium alloy ingot into a 1.5t induction melting furnace for melting. The mass percentages of Cu and Ti in the alloy ingot are 0.6% and 0.3% respectively, and the impurity content does not exceed 0.05%. When the alloy is melted The temperature of the melt exceeds 620°C, and it is kept for 20 minutes. During the heat preservation process, the melt temperature is controlled below 650°C, and then the zinc-copper-titanium alloy melt is transferred into the ladle.

[0028] (2) Move the alloy melt in the ladle into the arc-shaped continuous casting machine. The mold is a tubular copper mold with an inner diameter of 80mm. The pouring temperature is controlled at 570°C-580°C. The vibration frequency of the mold vibration mechanism is 25-28kHz, the casting speed of the casting slab at the lower mouth of t...

Embodiment 2

[0033] A preparation method for a novel zinc alloy wire material and coating for electric arc spraying, comprising the following steps:

[0034] (1) Put the custom-made zinc-copper-titanium alloy ingot into a 1.5t induction melting furnace for melting. The mass percentages of Cu and Ti in the alloy ingot are 0.6% and 0.3% respectively, and the impurity content does not exceed 0.05%. When the alloy is melted The temperature of the melt exceeds 620°C, and it is kept for 20 minutes. During the heat preservation process, the melt temperature is controlled below 650°C, and then the zinc-copper-titanium alloy melt is transferred into the ladle.

[0035] (2) Move the alloy melt in the ladle into the arc-shaped continuous casting machine. The mold is a tubular copper mold with an inner diameter of 80mm. The pouring temperature is controlled at 570°C-580°C. The vibration frequency of the mold vibration mechanism is 25-28kHz, the casting speed of the casting slab at the lower mouth of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com