Butt joint process of φ1.2mm magnesium welding wire

A welding wire and process technology, which is applied in the field of butt joint process of Φ1.2mm magnesium welding wire, can solve the problems of reducing hard brittleness and easy wire breakage, and achieve the effects of reducing hard brittleness, easy operation and simple welding method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

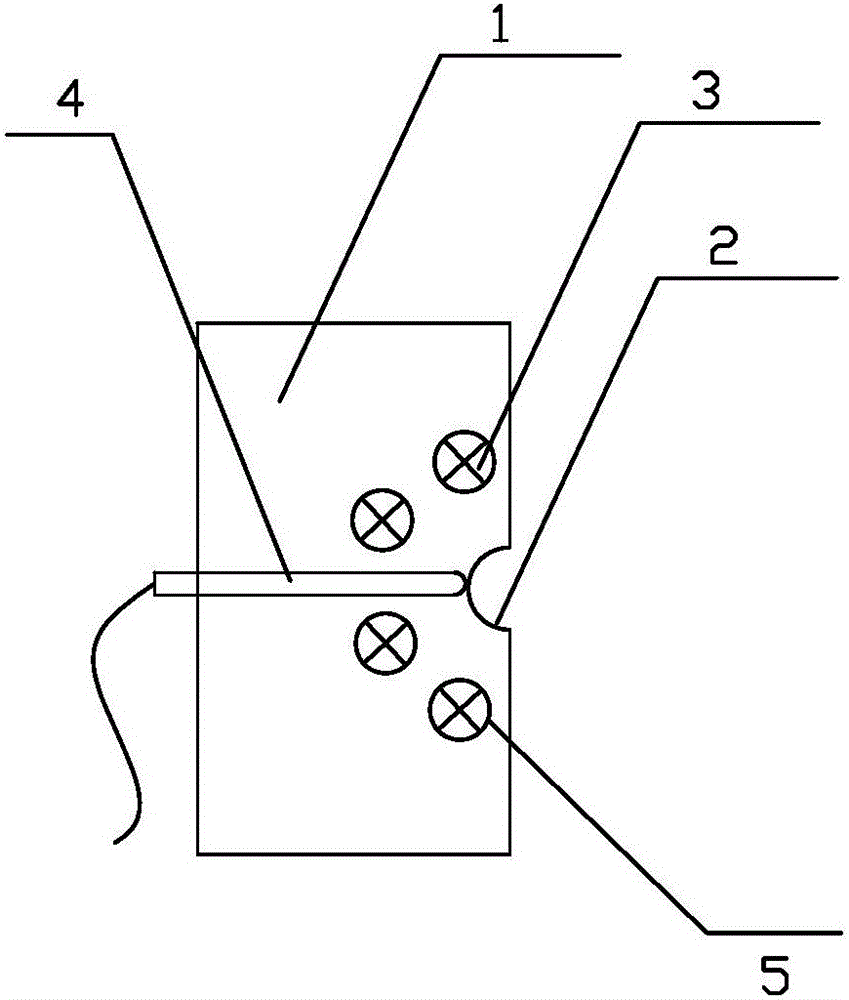

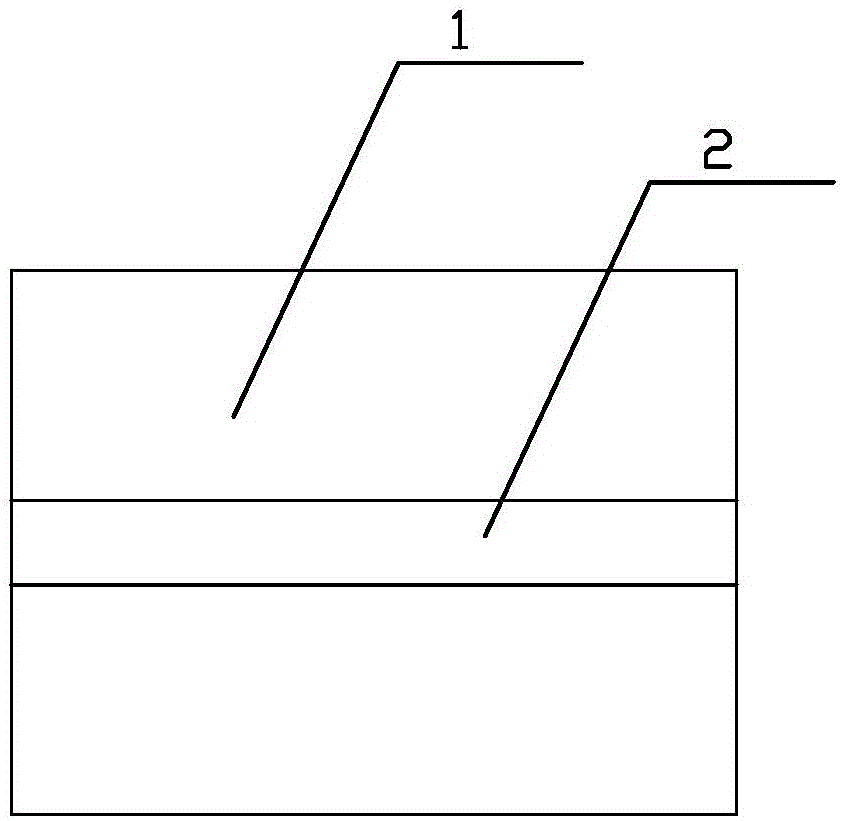

[0022] Such as figure 1 , the butt mold of the present embodiment Φ1.2mm magnesium welding wire includes 4 sets, including 4 sets, the structure of 4 sets of molds is the same, each set is divided into an upper mold and a lower mold, the upper mold includes a mold body 1, and the upper mold and the lower mold A vertical semicircular groove 2 is set on one side of the mold body 1 that is fastened by the mold, and four evenly distributed through holes 5 are arranged around the groove 2, and a heating wire 3 is installed on the through hole 5, and the heating wire 3 is connected to the power supply, and the middle of the mold body 1 The thermocouple 4 is arranged horizontally, and the thermocouple 4 is connected to the temperature controller; the structure of the lower mold is the same as that of the upper mold.

[0023] The mold is ordinary steel plate.

[0024] The thickness of the mold is not less than 30mm, the length is 50mm, and the width is 60mm.

[0025] The grooves 2 h...

Embodiment 2

[0030] The mold that this embodiment uses is identical with embodiment 1. The difference is that the thickness of the mold is not less than 30mm, the length is 20mm, and the width is 40mm.

[0031] Butt joint process of Φ1.2mm magnesium welding wire:

[0032] First, install the 2.0mm mold on the punching machine, connect the power supply, heat the mold, and adjust the temperature controller to 430°C. When the temperature rises to 430°C, start the butt joint of Φ1.2mm magnesium welding wire, and place the joint to be butted on the groove of the mold , the two joints are overlapped by 10mm, and the stamping is repeated 10 times; the molds of Φ1.6mm, Φ1.4mm, and Φ1.2mm are installed in sequence, and the operation process of the Φ2.0mm mold is repeated. , each 10 times. Use sandpaper to grind the joints of the joints to make the joints smooth and weld the wires to complete the butt joint.

Embodiment 3

[0034] The mold that this embodiment uses is identical with embodiment 1. The difference is that the thickness of the mold is not less than 30mm, the length is 40mm, and the width is 50mm.

[0035] Butt joint process of Φ1.2mm magnesium welding wire:

[0036] First, install the 2.0mm mold on the punching machine, connect the power supply, heat the mold, and adjust the temperature controller to 410°C. When the temperature rises to 410°C, start the butt joint of Φ1.2mm magnesium welding wire, and place the joint that needs to be butt in the mold groove 2 On the top, the two joints overlap by 20mm, and the stamping is repeated 12 times; the molds of Φ1.6mm, Φ1.4mm, and Φ1.2mm are installed in sequence, and the operation process of the Φ2.0mm mold is repeated. Stamping, 12 times each. Use sandpaper to grind the joints of the joints to make the joints smooth and weld the wires to complete the butt joint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com