Flat membrane handpiece for producing PET tape yarn

A flat film and die technology, applied in spinneret assemblies, textiles and papermaking, etc., can solve the problems of low melt viscosity, easy to break during drafting, easy to break filaments, etc., to meet the requirements of industrial production, avoid damage, Reasonable effect of mold structure design

Active Publication Date: 2013-09-11

ZHENGZHOU UNIV

View PDF9 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The use of waste PET to produce flat yarn still faces the problems of low melt viscosity and easy breakage of draft

In order to avoid damage to the side of the flat wire by the cutter in the post-slitting process, it

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Login to View More

Abstract

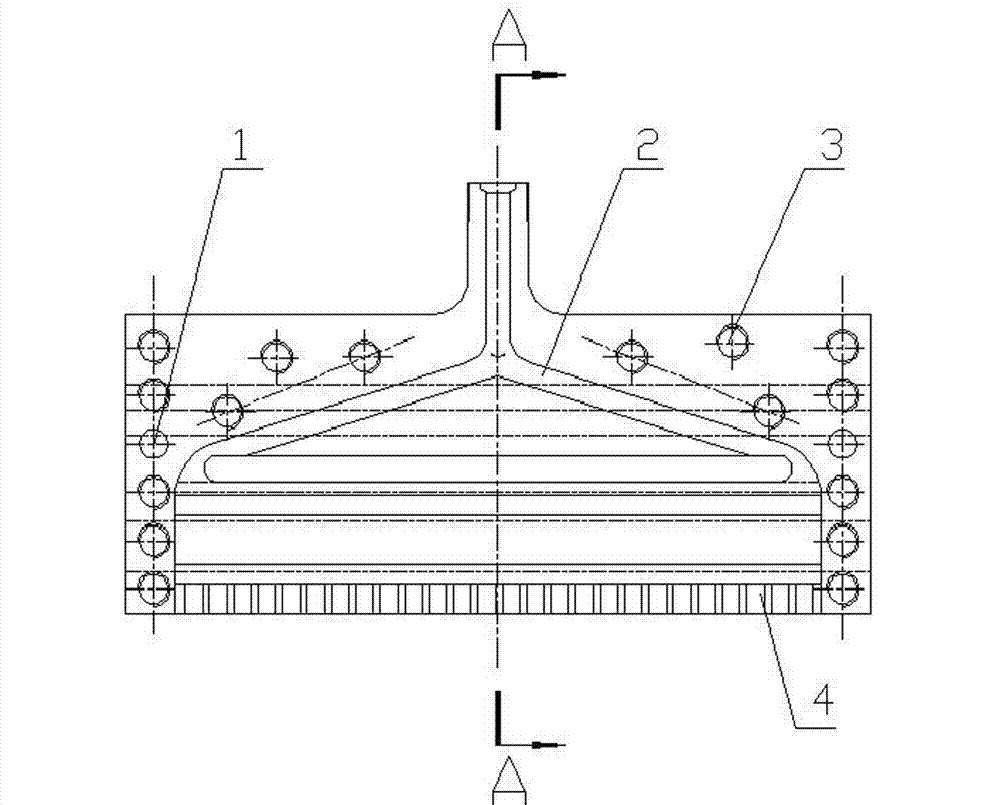

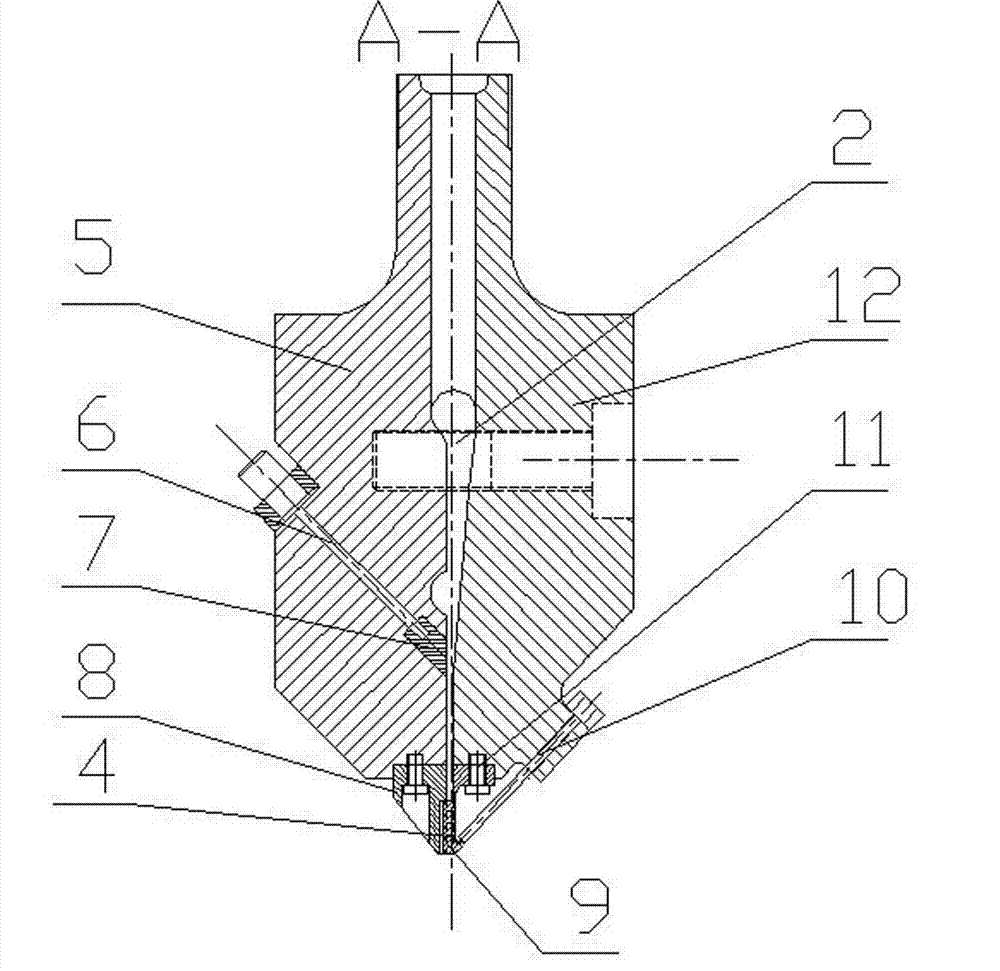

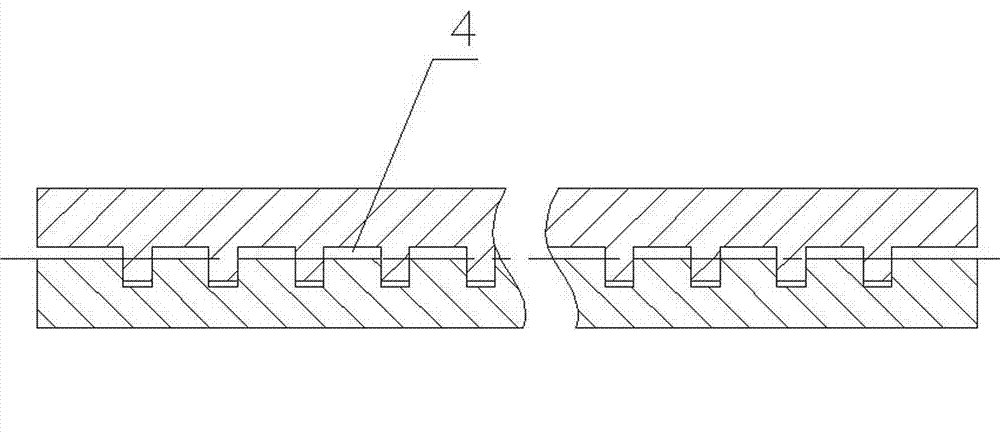

The invention discloses a flat membrane handpiece for producing PET tape yarn and belongs to the mechanical field of high polymer material machining. The flat membrane handpiece for producing the PET tape yarn is one of core devices of a tape yarn production line. The flat membrane handpiece comprises a yarn spraying hole and a flow channel and is characterized in that a flow retaining block is arranged in the flow channel. The yarn spraying hole is composed by meshing an upper die lip and a lower die lip. The upper die lip and the lower die lip are respectively provided with an adjustable bolt. The adjustable bolts and the flow retaining block are used for regulating flow of PET fondant. PET primary tape yarn with a rectangular cross section is directly extruded out of a meshed yarn spraying micro hole. The adjustable bolts extrude the lower die lip and adjust the size of the rectangular hole by means of elasticity of the lower die lip so as to achieve the aim of controlling the thickness of the PET tape yarn. The tape yarn is formed after cooling and traction forming techniques. The flat membrane handpiece for producing the PET tape yarn can effectively solve the problem that yarn is prone to fracture in the process of traction and weaving, dies are reasonable in structural design and industrial production can be met.

Description

technical field [0001] The invention relates to a flat film machine head for producing PET flat yarns for woven bags, belonging to the field of polymer material processing machinery. Background technique [0002] The biggest use of polypropylene (PP) is to produce woven bags. Because polypropylene woven bags are easy to separate from the packaging, light in weight and low in cost, they have been widely used in the packaging of large-scale products such as chemicals, mineral powders, building materials and grains. . However, due to poor weather resistance and easy oxidative degradation of PP, the mechanical strength of woven bags is greatly reduced during storage, which affects the packaging effect. [0003] Polyethylene terephthalate (PET) has good mechanical properties and weather resistance, and my country has become the largest producer and consumer of PET. However, under natural conditions, PET is not easy to degrade, and discarded PET will cause environmental pollutio...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): D01D4/00

Inventor 牛明军郭凯陈金周张丽毕婷婷宋小辉李林

Owner ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com