Preparation process of high-toughness zinc-based copper-titanium alloy wire

A titanium alloy wire and a preparation process technology are applied in the field of preparation technology of high-toughness zinc-based copper-titanium alloy wire, which can solve problems such as difficulty in forming zinc-based copper-titanium alloy wire, and achieve industrialization, good toughness, and solution The effect of easy wire breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation process of high-toughness zinc-based copper-titanium alloy wire, comprising the following steps:

[0023] (1) Design the composition of the zinc-based copper-titanium alloy, in which the contents of Cu and Ti are 0.6% and 0.05%, respectively.

[0024] (2) Use a 2t resistance furnace to smelt zinc-based copper-titanium alloys. In the smelting process, firstly melt zinc ingots with a purity of 99.9%, and the smelting temperature is between 630°C and 650°C, and then the purchased Zn-5Cu and Zn- Add the 2Ti master alloy into the pure zinc melt, and keep it warm for 1h after the master alloy is completely melted. Next, rod-shaped ingots of the zinc-based copper-titanium alloy with a diameter of 100 mm were prepared on a continuous casting machine, and cut into short rods of 1200 mm.

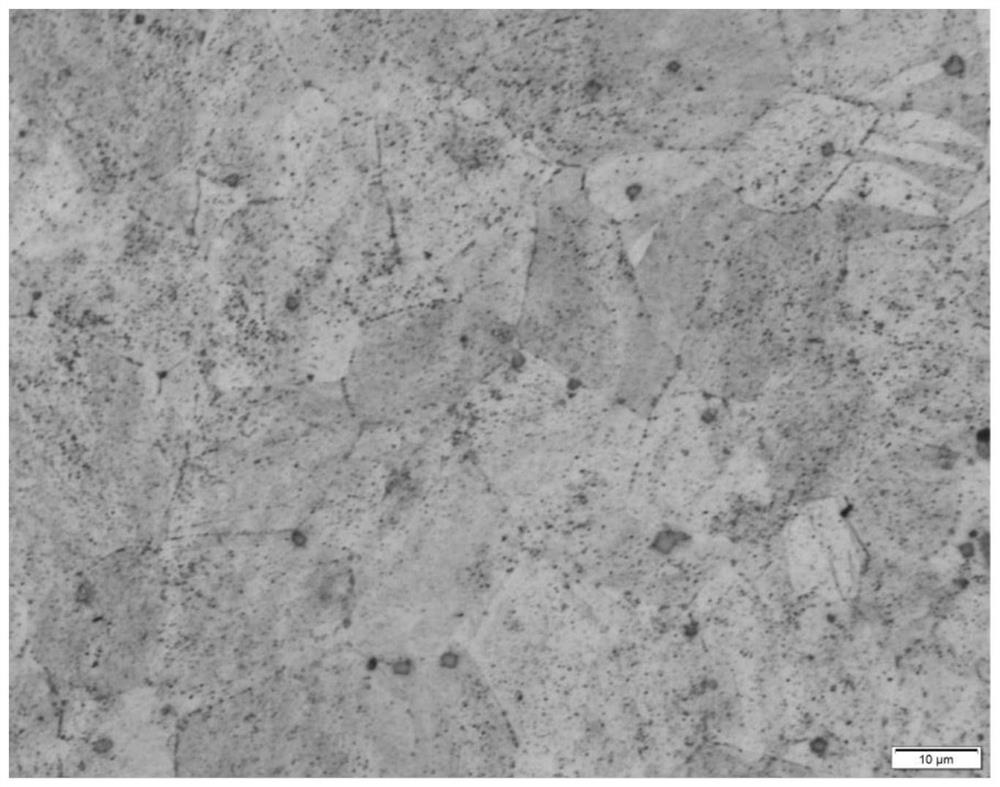

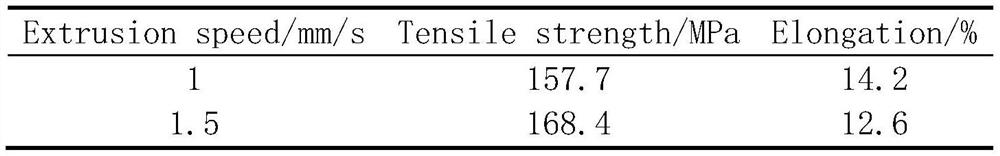

[0025] (3) Inductively heat a 1200mm zinc-based copper-titanium alloy rod to 370°C-380°C, and quickly move the rod into an extruder for hot extrusion, extruding it into a rod wit...

Embodiment 2

[0028] A preparation process of high-toughness zinc-based copper-titanium alloy wire, comprising the following steps:

[0029] (1) Design the composition of the zinc-based copper-titanium alloy, in which the contents of Cu and Ti are 0.6% and 0.05%, respectively.

[0030] (2) Use a 2t resistance furnace to smelt zinc-based copper-titanium alloys. In the smelting process, firstly melt zinc ingots with a purity of 99.9%, and the smelting temperature is between 630°C and 650°C, and then the purchased Zn-5Cu and Zn- Add the 2Ti master alloy into the pure zinc melt, and keep it warm for 1h after the master alloy is completely melted. Next, rod-shaped ingots of the zinc-based copper-titanium alloy with a diameter of 100 mm were prepared on a continuous casting machine, and cut into short rods of 1200 mm.

[0031] (3) Inductively heat a 1200mm zinc-based copper-titanium alloy rod to 370°C-380°C, and quickly move the rod into an extruder for hot extrusion, extruding it into a rod wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com