Composite material containing liquid crystal polymer as well as processing and forming method and application of composite material

A liquid crystal polymer, processing and molding technology, applied in the direction of metal pattern materials, chemical instruments and methods, synthetic resin layered products, etc., can solve the problems of large waste water discharge and adverse effects on performance, so as to eliminate the generation of waste water and avoid various Non-uniform mechanical properties and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

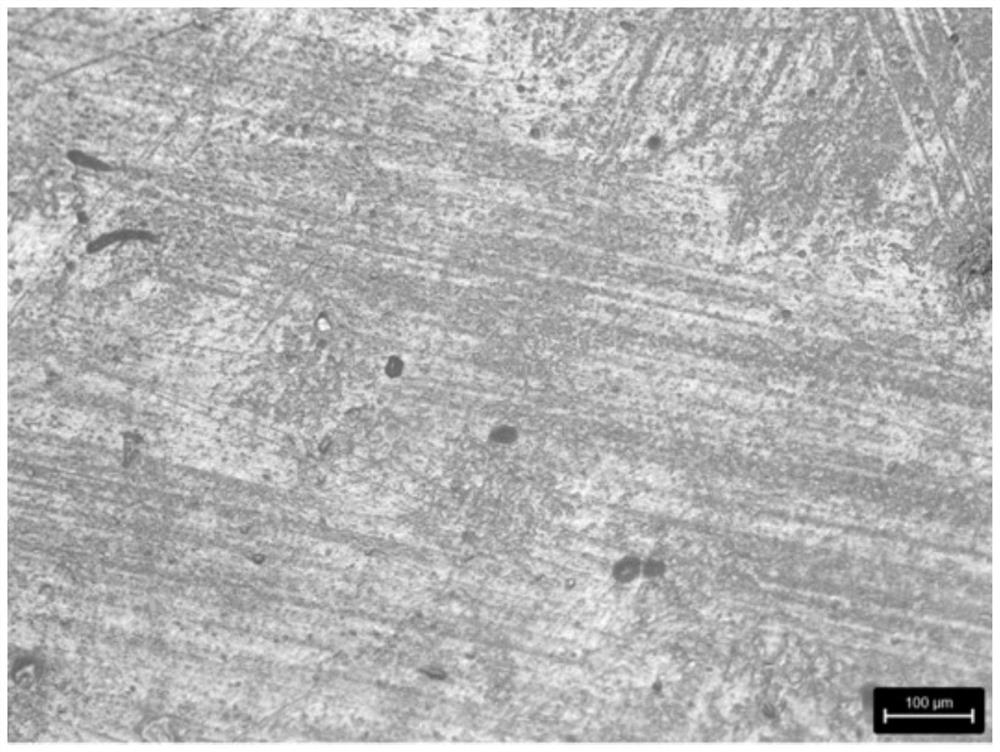

[0054] This embodiment discloses a method for processing and forming an aramid fiber-LCP sheet. On the mirror polished stainless steel plate, according to 0.05g / cm 2 Spread a layer of Vectra A950 LCP resin powder (self-made from pellets) with a density of 0.1 g / cm 2 Spread a layer of LCP powder with the same density as the first layer, cover it with a layer of aramid cloth in the same direction of warp and weft as the first layer, and then cover it with 0.05g / cm 2 Spread a layer of LCP powder at a density of . Finally, another layer of smooth stainless steel plate is covered on the top, and the relative position of the two plates is fixed with a clamp to prevent slippage.

[0055] Place the above-mentioned sandwich structure in an oven with a temperature control device, and adjust the pressure by increasing or decreasing the weight pressed above.

[0056] In the absence of external pressure, the sample was kept at 240°C for 2h and 250°C for 1h; then 0.2kg / cm 2 The pressure...

Embodiment 2

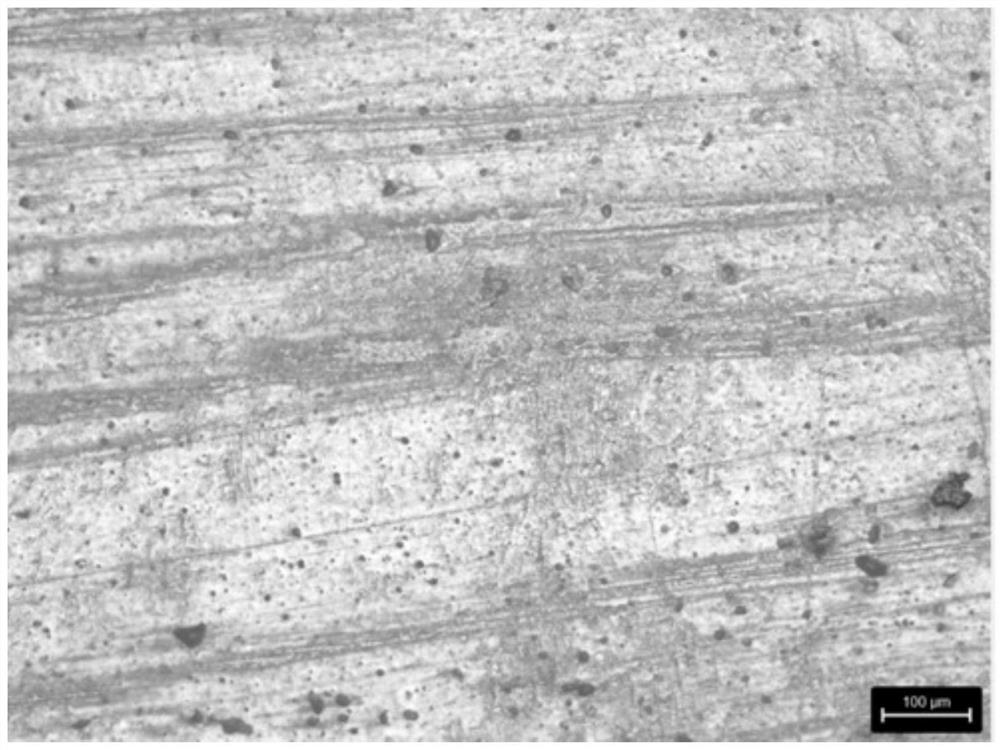

[0059] This embodiment discloses a processing and molding method of aramid fiber-liquid crystal polymer composite parts.

[0060] In the mold, aramid cloth (the aramid cloth is the same as in Example 1) and LCP powder (Vectra A950 resin is used in this embodiment) are laminated to form a sandwich structure. According to the total volume of the part, the density of aramid is 1.44g / cm 3 and the density of LCP resin is 1.4g / cm 3 Carry out the calculation of the filling quantity, which is 101% of the total volume of the part.

[0061] Place the above-mentioned sandwich structure in an oven with a temperature control device, and adjust the pressure by increasing or decreasing the weight pressed above.

[0062] In the absence of external pressure, the sample was kept at 240°C for 2h and 250°C for 1h; then 0.2kg / cm 2 The pressure is raised to 280°C with a temperature gradient of 1°C / min; then increase the load to 0.5kg / cm 2 , the temperature was raised to 310°C at a rate of 5°C / m...

Embodiment 3

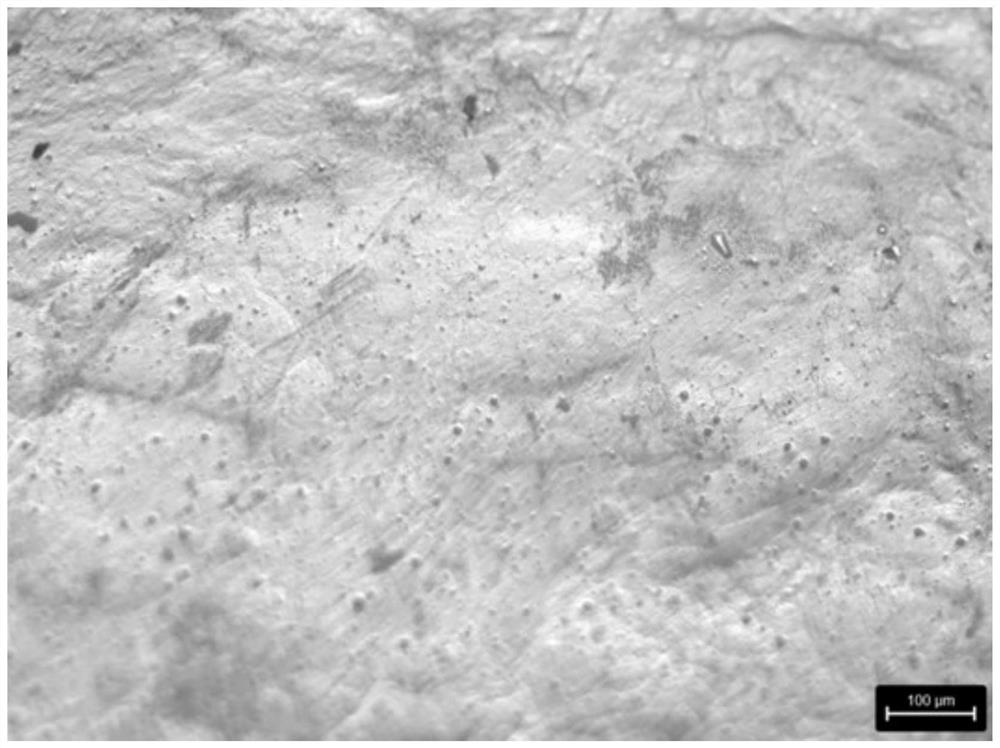

[0066] This embodiment discloses a method for processing and forming an aramid fiber-liquid crystal polymer composite film. The aramid fiber used is Teijin Twaron long fiber with a diameter of about 0.015mm (nominal denier 1.9-2.5 denier). The liquid crystal polymer fiber used is a self-made fiber by melt spinning using Vectra A 950 resin, and its diameter is about 0.2mm measured under a microscope at multiple points.

[0067] The yarn formed by blending the above two fibers is blended into a cloth by a weaving method. Two layers of this fabric are superimposed and clamped top and bottom with polished stainless steel plates.

[0068] Place the above-mentioned sandwich structure in an oven with a temperature control device, and adjust the pressure by increasing or decreasing the weight pressed above.

[0069] In the absence of external pressure, the sample was kept at 240°C for 2h and 250°C for 1h; then 0.2kg / cm 2 The pressure is raised to 280°C with a temperature gradient of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| breaking force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com