Method for detecting acetaldehyde in liquor sample by using fluorescent probe

A technology for fluorescent probes and acetaldehyde, applied in fluorescence/phosphorescence, measurement devices, and material analysis through optical means, can solve problems such as complex operating procedures, long detection time, and high detection costs, and achieve a wide linear range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

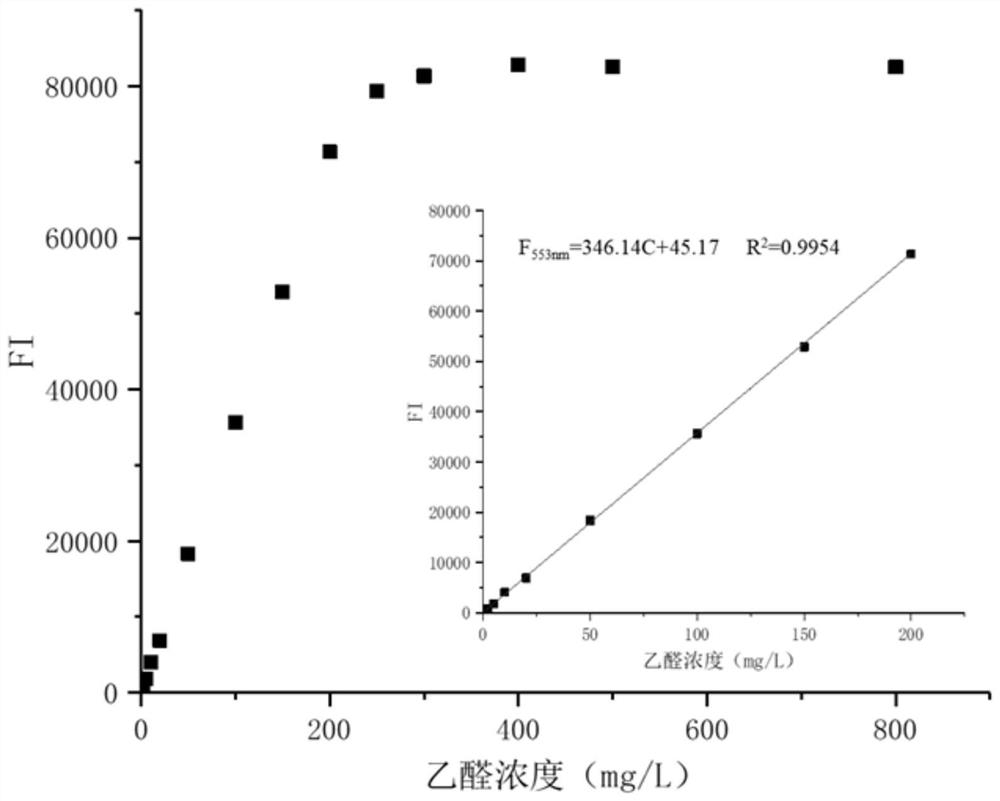

[0049] The construction of embodiment 1 quantitative detection model

[0050] (1) Using acetonitrile as a solvent to prepare a hydrochloric acid solution (pH=2) with a mass fraction of 2.96%; using acetonitrile as a solvent and DMSO as a co-solvent (10:1, v / v) to prepare a 600mg / L fluorescent probe solution;

[0051] (2) Prepare acetaldehyde standard solutions with a series of concentrations (0mg / L, 10mg / L, 20mg / L, 50mg / L, 100mg / L, 150mg / L, 200mg / L) with distilled water; Add 50 μL of hydrochloric acid solution, 50 μL of standard acetaldehyde solution, and 100 μL of fluorescent probe solution, and place it in a 5°C incubator for low-temperature reaction for 50 minutes to obtain a mixed system;

[0052] (3) Measure the fluorescence intensity F of the mixed system at 553nm on a fluorescence spectrometer 553nm , with the acetaldehyde concentration C as the abscissa, and the fluorescence intensity as the ordinate, the standard working curve (such as image 3 shown), the linear re...

Embodiment 2

[0053] The detection of acetaldehyde in embodiment 2 simulated wine samples

[0054] The content of acetaldehyde in the sample is determined by fluorescent probe, the specific operation process and experimental conditions are as follows:

[0055] 1. Sample treatment: Add 500 μL of acetaldehyde solution (1000 mg / L) to 50 ml of distilled water to prepare a 10 mg / L standard solution, distill the standard sample with a diacetyl distillation device, and the results of the concentration ratio and recovery rate are as follows: Figure 4 , it was found that the recovery effect is better when the concentration factor is not more than 5 times. Considering the distillation efficiency, the concentration factor should be selected as 5 times. The specific operation is as follows, take 50mL of wine sample, beer and other gas samples need to add a drop of defoamer, liquor, rice wine and wine samples need to be diluted 25 times with distilled water, use a diacetyl distillation device to disti...

Embodiment 3

[0070] The standard addition recovery verification of embodiment 3 detection method

[0071] The recovery rate of the method is investigated in the simulated solution system and the real wine sample system respectively. In the acetaldehyde simulated system: add 50 μ L / 100 μ L / 200 μ L of acetaldehyde stock solution ( 1g / L), prepare 3 parallel samples for each spiked amount; in the real wine system, add 50μL / 100μL / 200μL acetaldehyde stock solution (1g / L) to 50mL beer, add 500μL / 1000μL / 2000μL acetaldehyde stock solution (1g / L), add 250μL / 500μL / 1000μL acetaldehyde stock solution (1g / L) to 50mL rice wine and wine, prepare 3 parallel samples for each spiked amount. Then, the above-mentioned fluorescent probe detection method was used to detect the content of acetaldehyde, and the results are shown in Table 1.

[0072] Table 1 Standard addition recovery experimental results (n=3)

[0073]

[0074] Note: Samples 1-3 are acetaldehyde standard solutions, samples 4-6 are beer sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com