Novel process for purifying solanesol based on chemically modified diatomite

A technology of chemical modification and diatomite, applied in the field of separation and purification of solanesol, which can solve the problems of unsuitable treatment of waste, complex processing process, high production cost, etc., and achieve the effects of reduced use, easy separation process and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

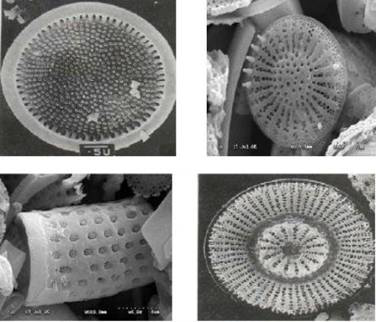

[0022] Such as Figure 1-3 Shown, a kind of new technology of purifying solanesol based on chemically modified diatomite comprises the steps:

[0023] (1) Use a grinding bottle to grind 3.0g of diatomite into a fine powder with a particle size of 500 mesh, add 12ml of sulfuric acid with a concentration of 3mol / L to the fine powder to form a solution, and then place the grinding bottle containing the solution in a constant temperature water bath In the oscillator, shake at room temperature for 45 minutes, wash the shaken solution to neutrality, then filter through a sieve with a pore size of 20-25 μm, and dry the obtained filtrate to constant weight to obtain modified diatomite;

[0024] (2) Add 0.3g of modified diatomite obtained in step (1) to 50ml of solanesol-containing extract to form a mixed solution, put the mixed solution in an airtight container 3, and place the airtight container 3 in a constant temperature water bath for oscillation In the container, shake at room t...

Embodiment 2

[0027] Such as Figure 1-3 Shown, a kind of new technology of purifying solanesol based on chemically modified diatomite comprises the steps:

[0028] (1) Use a grinding bottle to grind 3.0g of diatomite into a fine powder with a particle size of 800 mesh, add 8ml of nitric acid with a concentration of 3mol / L to the fine powder to form a solution, and then place the grinding bottle containing the solution in a constant temperature water bath In the oscillator, shake at room temperature for 55 minutes, wash the shaken solution to neutrality, then filter through a sieve with a pore size of 20-25 μm, and dry the obtained filtrate to constant weight to obtain modified diatomite;

[0029] (2) Add 0.8g of modified diatomite obtained in step (1) to 50ml of solanesol-containing extract to form a mixed solution, put the mixed solution in a closed container 3, and place the closed container 3 in a constant temperature water bath for oscillation In the container, shake at room temperatu...

Embodiment 3

[0032] Such as Figure 1-3 Shown, a kind of new technology of purifying solanesol based on chemically modified diatomite comprises the steps:

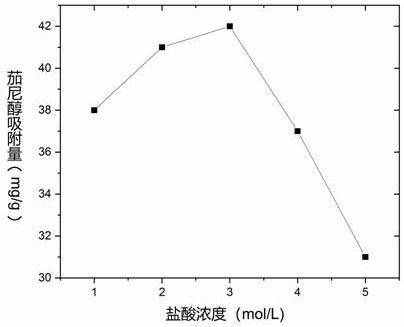

[0033] (1) Use a grinding bottle to grind 3.0g of diatomite into a fine powder with a particle size of 600 mesh, add 10ml of hydrochloric acid with a concentration of 3mol / L to the fine powder to form a solution, and then place the grinding bottle containing the solution in a constant temperature water bath In the oscillator, shake at room temperature for 50 minutes, wash the shaken solution to neutrality, then filter through a sieve with a pore size of 20-25 μm, and dry the obtained filtrate to constant weight to obtain modified diatomite;

[0034] (2) Add 0.5g of modified diatomite obtained in step (1) to 50ml of tobacco extract containing solanesol to form a mixed solution, put the mixed solution in a closed container 3, and place the closed container 3 in a constant temperature water bath In the oscillator, shake at room temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com