Hearth outlet NOx prediction method and system based on numerical simulation

A furnace outlet and numerical simulation technology, applied in CAD numerical modeling, measuring devices, instruments, etc., can solve the problems of NOx concentration measurement lag and inaccuracy, and achieve the effect of improving economy and denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

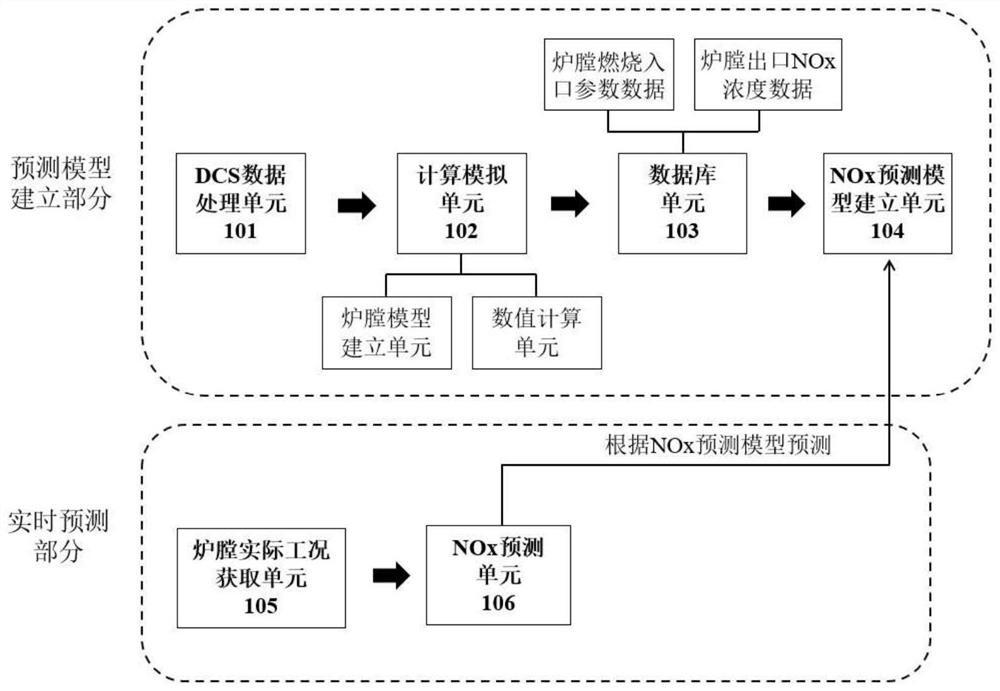

[0057] Such as figure 1 As shown, a numerical simulation-based furnace outlet NOx prediction system in this embodiment includes a prediction model part and a real-time prediction part, and the prediction model part includes a DCS data processing unit 101, a calculation simulation unit 102, a database unit 103 and a NOx prediction model The establishment unit 104, the real-time prediction part includes the furnace actual working condition acquisition unit 105 and the NOx prediction unit 106;

[0058] The DCS data processing unit 101 is used to extract the furnace combustion boundary conditions required for the numerical simulation calculation from the DCS system (Distributed Control System, DCS) of the coal-fired power station distributed control system;

[0059] The calculation and simulation unit 102 is used to perform numerical simulation calcula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com