Solvent-free self-cleaning UV resin environment-friendly coating and preparation method thereof

A self-cleaning, solvent-free technology, applied in coatings, anti-corrosion coatings, polyester coatings, etc., can solve the problems of poor coating stability, high cost of preparation methods, and no prospect of large-scale preparation, and achieve good hydrophobicity, The effect of excellent hydrophobicity, excellent acid and alkali resistance and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

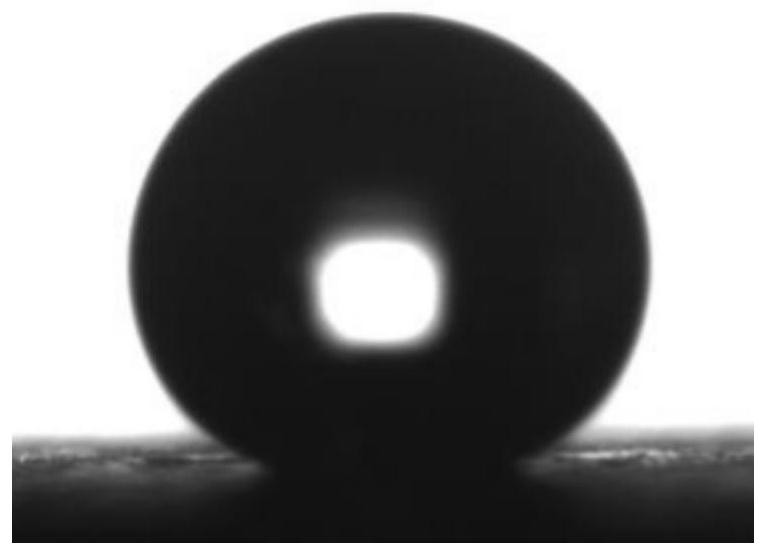

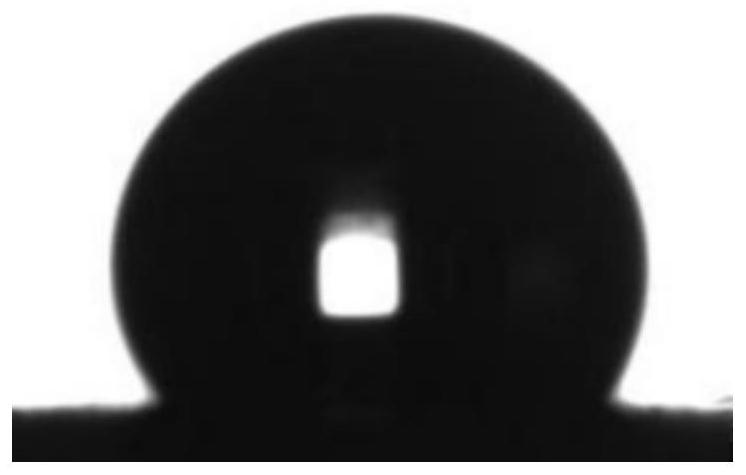

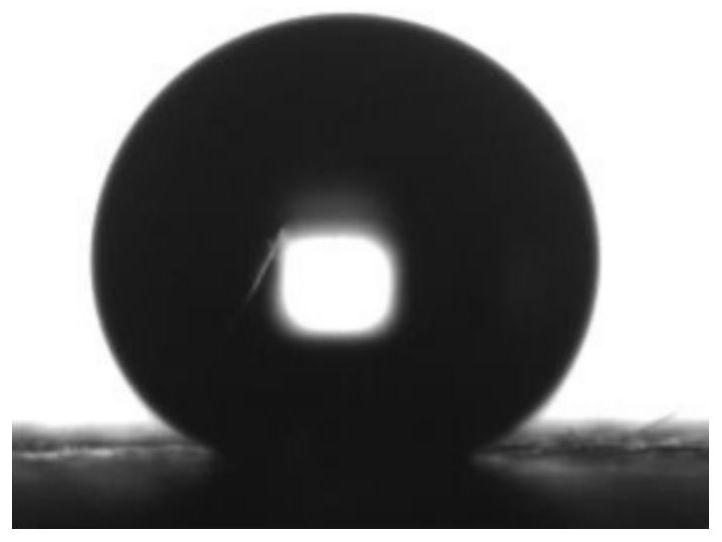

Image

Examples

preparation example Construction

[0026] The preparation method of described superhydrophobic self-cleaning coating comprises:

[0027] (1) Add γ-alumina powders with particle sizes of 200-300nm and 1.5-2μm to the modification solution, and the mass ratios are 1:45-50 and 1:55-60, respectively. Stirring at 40-60°C for 6 hours and then vacuum-drying with a vacuum degree of -0.1MPa to obtain modified γ-alumina powders with different particle sizes. Among them, the modified solution is 3-cyclohexylaminopropanesulfonic acid, octadecyldimethylbenzyl ammonium chloride, methyl Mixed aqueous solution of phenyldimethoxysilane and itaconic acid. Those skilled in the art should know that the modified γ-alumina powder obtained after the processing of 200-300 nm and 1.5-2 μm γ-alumina powders with different particle sizes still has different particle sizes.

[0028] (2) Mix hydroxyfluorosilicone oil, propylene glycol block polyether and dicobalt octacarbonyl in a weight ratio of 1:1.2~1.5:4~5, feed nitrogen gas, heat and...

Embodiment 1

[0034](1) Add γ-alumina powders with particle sizes of 200-300nm and 1.5-2μm to the modification solution, and the mass ratios are 1:45 and 1:55, respectively. After stirring at 40° C. for 6 h, vacuum drying was carried out at a vacuum degree of -0.1 MPa to obtain modified γ-alumina powder. Wherein, the modified solution is a mixed aqueous solution of 3-cyclohexylaminopropanesulfonic acid, octadecyldimethylbenzyl ammonium chloride, methylphenyldimethoxysilane and itaconic acid, and the weight ratio is 0.8 :1.2:10:18.

[0035] (2) Mix hydroxyfluorosilicone oil, propylene glycol block polyether and dicobalt octacarbonyl in a weight ratio of 1:1.2:4, pass nitrogen gas under airtight conditions, heat and stir at 40°C for 2 hours, and obtain polyether modified Non-toxic silicone as a leveling agent. Wherein, the nitrogen pressure is 0.5 psi.

[0036] (3) Mix the polyether modified silicone obtained in the above (2) with silane coupling agent KH-550, photoinitiator 1-hydroxy-cycl...

Embodiment 2

[0040] (1) Add γ-alumina powders with particle sizes of 200-300nm and 1.5-2μm to the modification solution, and the mass ratios are 1:48 and 1:58, respectively. After stirring at 50° C. for 6 h, vacuum drying was carried out at a vacuum degree of -0.1 MPa to obtain modified γ-alumina powder. Wherein, the modified solution is a mixed aqueous solution of 3-cyclohexylaminopropanesulfonic acid, octadecyldimethylbenzyl ammonium chloride, methylphenyldimethoxysilane and itaconic acid, and the weight ratio is 0.8 :1.3:12:19.

[0041] (2) Mix hydroxyfluorosilicone oil, propylene glycol block polyether and dicobalt octacarbonyl in a weight ratio of 1:1.3:4.5, pass nitrogen gas under airtight conditions, heat and stir at 45°C for 2 hours, and obtain polyether modified Non-toxic silicone as a leveling agent. Wherein, the nitrogen pressure is 0.5 psi.

[0042] (3) Mix the polyether modified silicone obtained in the above (2) with silane coupling agent KH-550, photoinitiator 1-hydroxy-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water droplet contact angle | aaaaa | aaaaa |

| Water droplet contact angle | aaaaa | aaaaa |

| Water droplet contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com