Styrene-acrylic emulsion grafted polypropylene composite material as well as preparation method and application thereof

A technology of styrene-acrylic emulsion and composite materials, which is applied in the field of polymer materials, can solve the problems of lack of polypropylene composite materials, etc., and achieve the effects of excellent reflective performance, enhanced reflective brightness, and improved use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the HDPE cross-linked masterbatch: HDPE is cross-linked under the action of the cross-linking initiator DCP (blended according to the ratio of 1000:1), and passed through a twin-screw extruder (process conditions: temperature 190-230°C , host speed 300-500rpm) extrusion, granulation, made of HDPE cross-linked masterbatch.

[0035] 2. Prepare barium sulfate masterbatch. The precipitated barium sulfate powder and the copolymerized polypropylene are extruded and granulated through an internal mixer. Among them, the precipitated barium sulfate powder is ZC-3000A and copolymerized polypropylene (melt index: 25-35g / 10min), both of which are added in a ratio of 4:1, and a certain amount of lubricant and antioxidant are added, passed through the internal mixer Mix and extrude to make barium sulfate masterbatch.

[0036] 3. Preparation of styrene-acrylic emulsion grafted polypropylene.

[0037] The styrene-acrylic emulsion is SD-588 nano-styrene-acry...

Embodiment 1

[0041] A polypropylene composite material grafted with styrene-acrylic emulsion, prepared by the following method:

[0042] Measure block copolymer PP K9930 35KG, HDPE cross-linking masterbatch 15KG, short glass fiber T435N 20KG, self-made barium sulfate masterbatch 25KG, self-made styrene-acrylic emulsion grafted PP compatibilizer 5KG, lubricant silicone masterbatch 0.5KG, Light Stabilizer Hindered Amine Light Stabilizer V703 0.2KG, Antioxidant 1010 0.3KG, Sorbitol Nucleating Agent 0.5KG, Masterbatch E1122 1KG.

[0043] Stir the raw materials for 10-15 minutes; then extrude, cool, dry and granulate in a twin-screw extruder (extrusion conditions: temperature 230°C, host speed 500rpm).

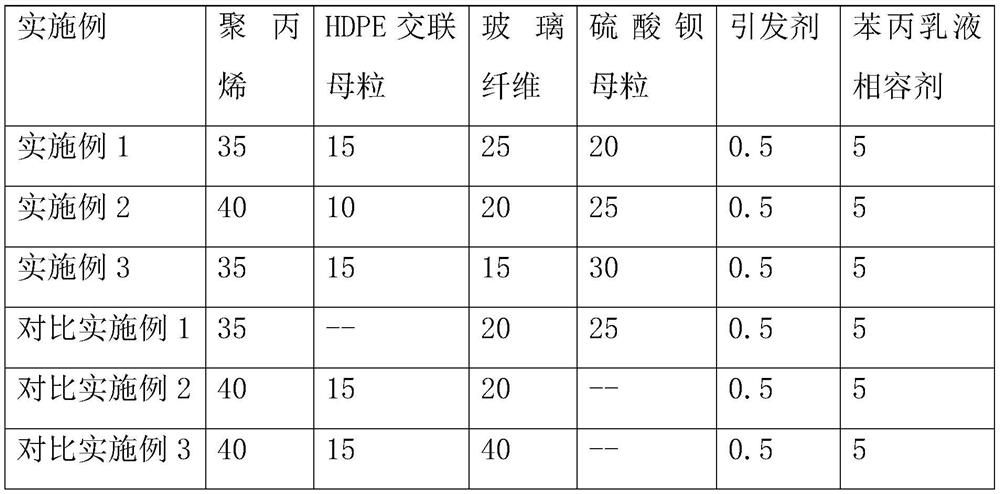

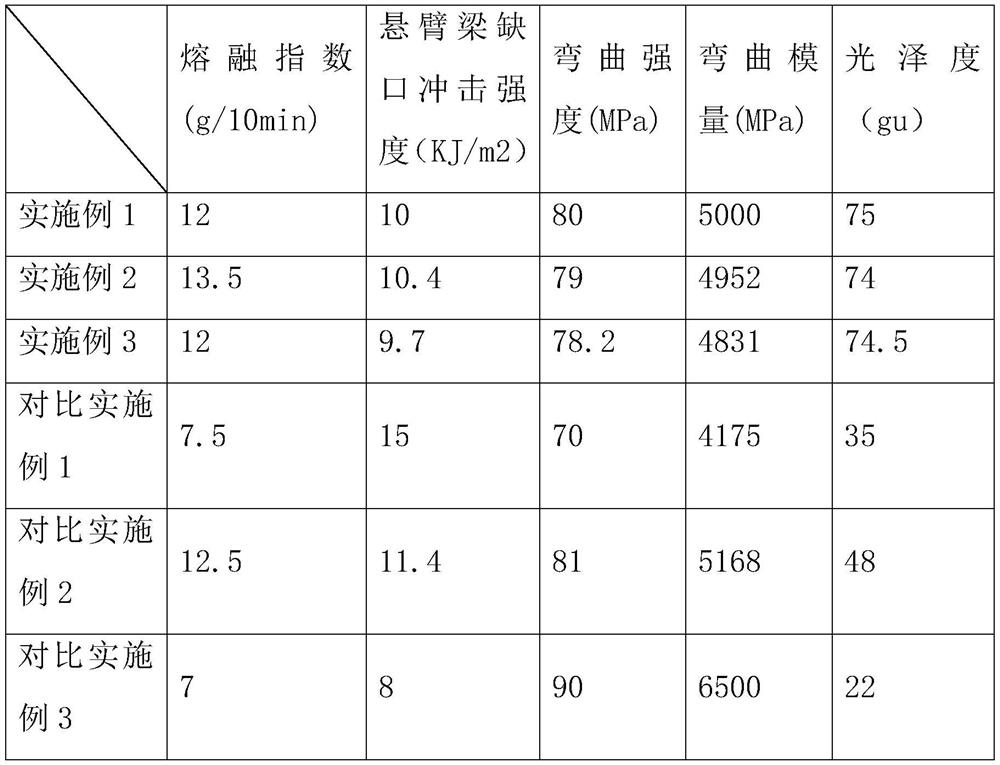

[0044] The difference between embodiment 2-3 and embodiment 1 is that the ratio of the mass of polypropylene, polyethylene cross-linked master batch, glass fiber, barium sulfate master batch, initiator, styrene-acrylic emulsion grafted polypropylene is different, The details are shown in Table...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com