Utilization method of 7-aminocephalosporanic acid production waste

A technology of amino cephalosporanic acid and waste, applied in the direction of fertilizer mixture, organic fertilizer, nitrogen fertilizer, etc., can solve the problems of limited application range, destruction of amino acid nutrition, large energy consumption, etc., to solve product cost and price upside down, bacteria The effect of reducing the physical volume of the body and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

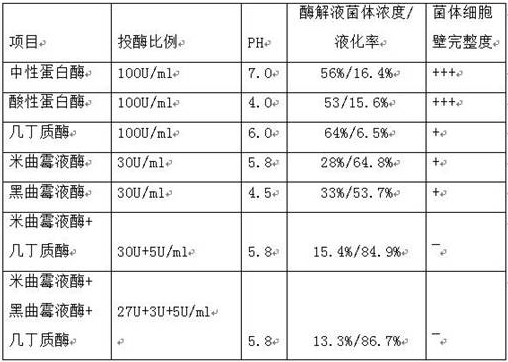

Method used

Image

Examples

Embodiment 1

[0036] The present embodiment provides a method for utilizing 7-aminocephalosporanic acid production waste, comprising the following steps:

[0037] (1) 500L of fresh fungus residue, the detected bacteria concentration is 86%, the solid content is 15.3%, adjust the pH to 5.8 with liquid caustic soda, add 45L of prepared Aspergillus oryzae lyase, add 40g of chitinase (100,000 U / g ), enzymatic hydrolysis at 58°C for 70h. The bacterial cell concentration of the enzymatic hydrolysis liquid was detected to be 14%, the liquefaction rate of organic matter was 83.6%, and the residue of cephalosporin C was not detected.

[0038] (2) 31.2 kg of substances such as calcium oxalate and some fibers were removed from the enzymatic hydrolysis solution by a decanter centrifuge.

[0039] (3) 50nm ceramic membrane ultrafiltration, during which water was added twice, 100L each time, and 625.5L of filtrate and 88.5L of filter residue were collected respectively.

[0040] (4) Concentrate the ultr...

Embodiment 2

[0043] The present embodiment provides a method for utilizing 7-aminocephalosporanic acid production waste, comprising the following steps:

[0044] (1) 920L of fresh bacterial residue, add 80L of ultrafiltration residue collected in step (3) of Example 1, mix, detect bacterial cell concentration 84.8%, solid content 15.1%, adjust PH5.8 with liquid caustic soda, add prepared rice Aspergillus lyase 88L, Aspergillus niger lyase 10L, add chitinase 60g (100,000 U / g), enzymolysis at 57°C for 70h. The concentration of bacteria in the enzymatic hydrolysis solution was 13.4%, the liquefaction rate of organic matter was 85.9%, and the residue of cephalosporin C was not detected.

[0045] (2) 72.3 kg of substances such as calcium oxalate and fiber were removed from the enzymatic hydrolysis solution by a continuous sedimentation centrifuge

[0046] (3) The centrifugate was ultrafiltered with a 20nm ceramic membrane, during which water was added twice, 150L each time, and the filtrate 11...

Embodiment 3

[0065] Add 15kg of plant stalks or the last batch of dry organic fertilizer raw materials to 72.3kg of centrifuged slag in Example 2, adjust the moisture content, insert Aspergillus oryzae ¸ Aspergillus niger or organic fertilizer composite strains for accumulation and fermentation, and turn the pile in the middle for 3-5 Lower the temperature for the second time. After the temperature drops, the moisture content is detected to be 21.6%. Spread it out to dry or dry until the moisture content is ≤15%, which is the basic raw material of organic fertilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com