Numerical control machining method for diamond blade with crown

A processing method and rhombus technology, applied in the field of CNC machining with its own crown rhombus blade, can solve the problems of low machining accuracy and low machining efficiency, and achieve the effects of improving machining efficiency and accuracy, saving tools, and improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

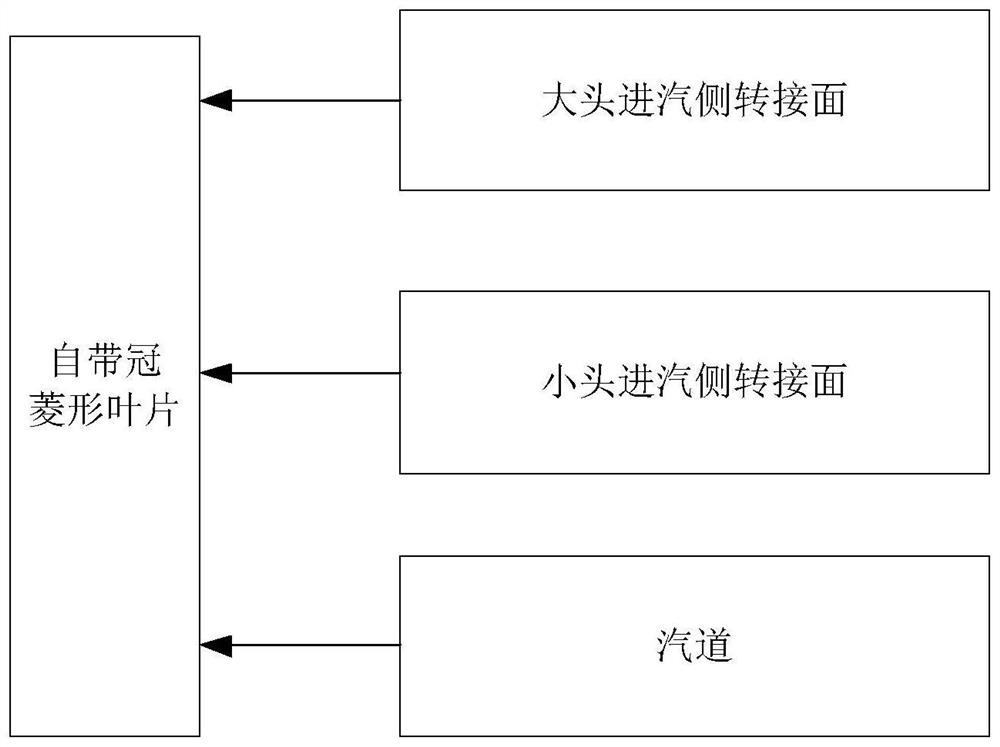

[0019] Combine below figure 1 Illustrate the present embodiment, a kind of numerical control processing method of own crown rhombus blade described in the present embodiment, it comprises:

[0020] Machining of the transfer surface on the steam inlet side of the bulk head: positioning with the steam outlet side and the back radial direction, with the steam inlet side facing upwards, and milling the transfer surface of the steam inlet side of the bulk head with a fixed profile;

[0021] Processing of the transfer surface on the steam inlet side of the small head: the inner radial face of the blade is positioned downwards, and a margin of 5mm height is removed at the back radial of the steam inlet side of the big head and the steam inlet side of the small head, and then the steam inlet side of the small head is rotated. Fixed profile milling at interface;

[0022] Machining of the steam channel: Use small ball-end cutters to partially mill the two ends of the steam channel, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com