Lithium ion battery positive electrode slurry and preparation method thereof

A lithium-ion battery and positive electrode slurry technology, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve problems such as gel, achieve simple process routes, good dispersibility, and alleviate supply shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

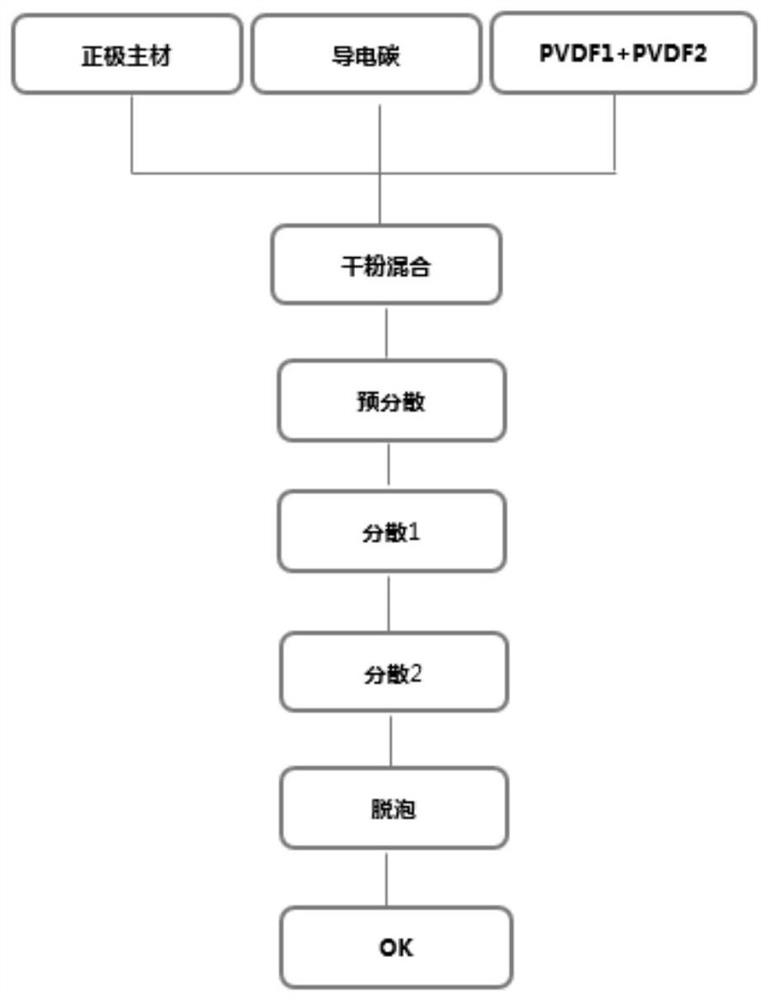

[0041] The preparation method of lithium ion battery cathode slurry, comprises the following steps:

[0042] 1) Weigh 97 parts by mass of positive active material lithium iron phosphate, 1 part of conductive carbon black powder, and 2 parts of binder. The binder is PVDF1 modified by mass ratio containing hexafluoropropylene group: PVDF2 of model HSV900 =5:5, add lithium iron phosphate, conductive carbon black powder and binder into a double planetary mixing tank for dry mixing, the dispersion revolution speed is 20rpm, the rotation speed is 500rpm, and the dispersion time is 30min;

[0043] 2) Add N-methylpyrrolidone NMP for pre-dispersion, the dispersion revolution speed is 10rpm, the rotation speed is 200rpm, and the dispersion time is 30min to form a semi-dry powder slurry with a solid content of 73% (mass percentage);

[0044] 3) Then add NMP to disperse, the dispersion revolution speed is 20rpm, the rotation speed is 500rpm, the dispersion time is 60min, and the solid con...

Embodiment 2

[0049] The preparation method of lithium ion battery cathode slurry, comprises the following steps:

[0050]1) Take by weight 97 parts of positive electrode active material lithium iron phosphate, 1 part of conductive carbon black powder, and 2 parts of binder; = 4:6 composition, adding lithium iron phosphate, conductive carbon black powder, and binder into a double planetary mixing tank for dry mixing, the dispersion revolution speed is 30rpm, the rotation speed is 800rpm, and the dispersion time is 45min;

[0051] 2) Add NMP for pre-dispersion, the dispersion revolution speed is 10rpm, the rotation speed is 200rpm, and the dispersion time is 30min to form a semi-dry powdery slurry with a solid content of 72% (mass percentage);

[0052] 3) Then add NMP to disperse, the dispersion revolution speed is 20rpm, the rotation speed is 500rpm, the dispersion time is 60min, the solid content is reduced to 67%, and a plasticine-like slurry is formed;

[0053] 4) Then add NMP for dispe...

Embodiment 3

[0057] The preparation method of lithium ion battery cathode slurry, comprises the following steps:

[0058] 1) Take by weight 97 parts of positive electrode active material lithium iron phosphate, 1 part of conductive carbon black powder, and 2 parts of binder, and the binder is composed of PVDF1 containing hexafluoropropylene group by mass ratio: PVDF2 of model HSV900 =3:7, add lithium iron phosphate, conductive carbon black powder, and binder into a double planetary mixing tank for dry mixing, the dispersion revolution speed is 30rpm, the rotation speed is 600rpm, and the dispersion time is 35min;

[0059] 2) After step 1), add NMP for pre-dispersion, the dispersion revolution speed is 10rpm, the rotation speed is 200rpm, and the dispersion time is 30min, forming a semi-dry powdery slurry with a solid content of 70% (mass percentage);

[0060] 3) Add NMP for dispersion, the dispersion revolution speed is 20rpm, the rotation speed is 500rpm, the dispersion time is 60min, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com