A kind of ordered basic anion exchange membrane and its preparation method and application

An alkaline anion and anion technology, applied in electrochemical generators, fuel cells, electrical components, etc., can solve the problems of disorder, hindering water and ion transmission, and high tortuousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

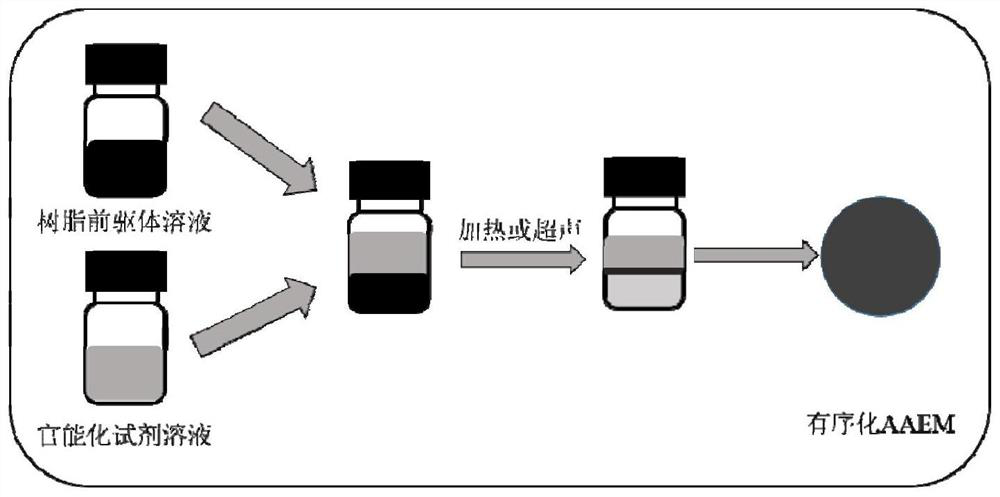

Method used

Image

Examples

Embodiment 1

[0032] Dissolve polystyrene-ethylene-butylene-styrene (SEBS) with a styrene block content of 30wt.% in organic reagent chloroform, stir mechanically, protect with nitrogen, raise the temperature to 55°C, and then add SnCl 4 and BCMB, where SEBS with chloroform, BCMB and SnCl 4 The mass volume ratios are 1g:30mL, 1g:4.6mL and 1g:2.0mL respectively, react for 12h, pour the reacted solution into anhydrous methanol, after the polymer is precipitated, suction filter, wash with deionized water to medium properties, and then dried in a vacuum oven at 60°C to obtain chloromethylated polystyrene-ethylene-butylene-styrene (CMSEBS).

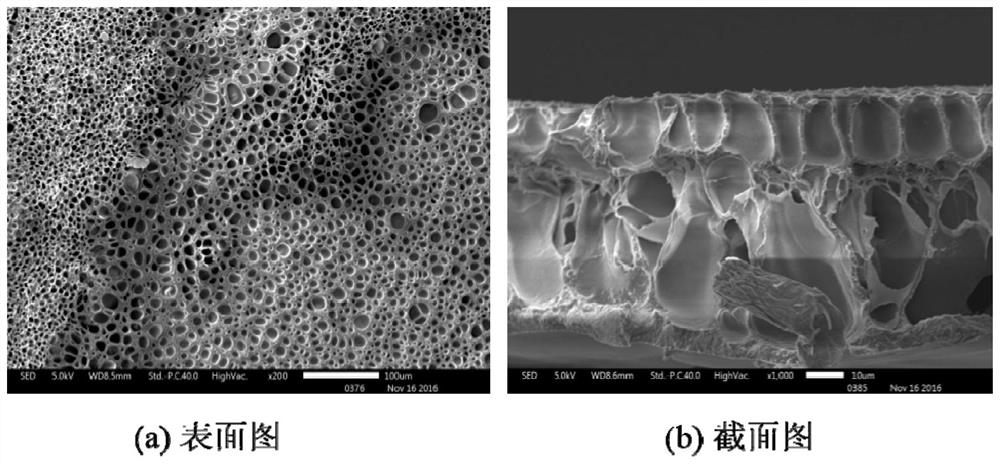

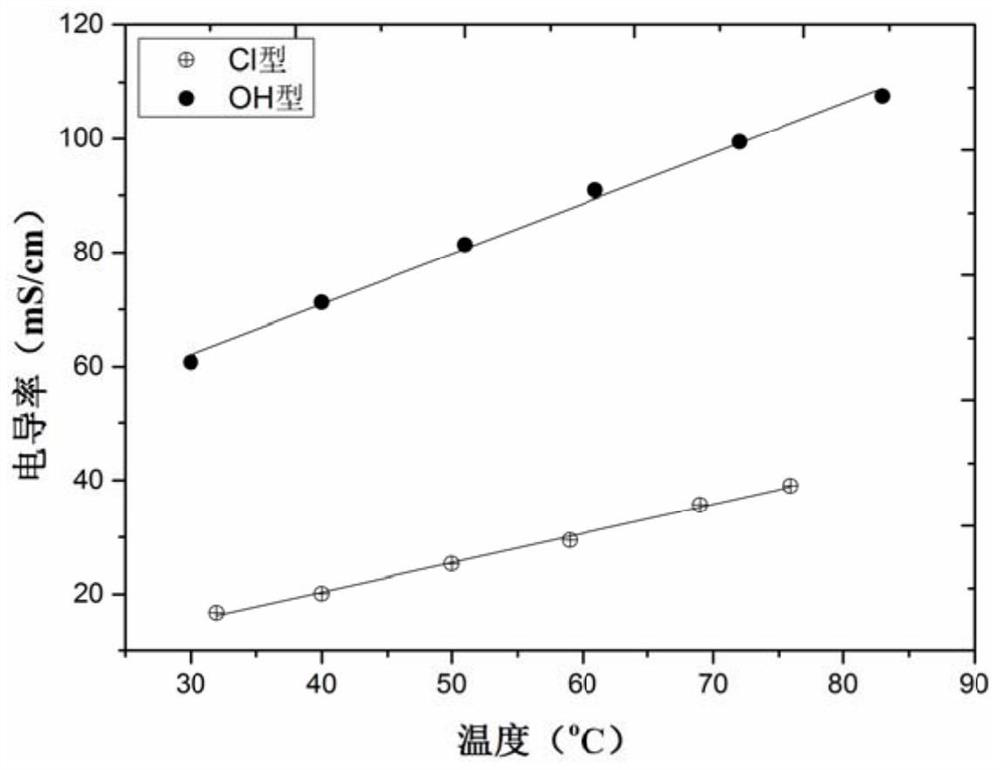

[0033] Weigh 0.25 g of polystyrene-polyethylene-polybutylene triblock polymer (CMSEBS) after chloromethylation, and dissolve it in 10 mL of chloroform (under room temperature, dissolve with magnetic stirring) to obtain anion exchange Resin precursor solution. Then measure 1 mL of trimethylamine aqueous solution (mass fraction about 33%), add it to 10 mL o...

Embodiment 2

[0037] Synthesis of chloromethylated polysulfone: Weigh 5 grams of polysulfone polymer resin, dissolve it in N,N-dimethylformamide, and prepare a resin solution with a mass fraction of 5%. The catalyst anhydrous tin tetrachloride and the chloromethylation reagent chloromethyl methyl ether are added sequentially, and the reaction is carried out at room temperature for 6 hours, and the chloromethylated polysulfone is obtained after filtering, precipitating, washing and drying.

[0038] Weighed 0.25 g of chloromethylated polysulfone, and dissolved it in 10 mL of chlorobenzene (dissolved by magnetic stirring at room temperature) to obtain an anion exchange resin precursor solution. Then measure 1 mL of trimethylamine aqueous solution (mass fraction about 33%), add it to 10 mL of water for dilution, then add 0.1 g of hexadecyltrimethylammonium bromide, and stir magnetically at room temperature to dissolve. The anion exchange resin precursor solution was poured into a cylindrical wa...

Embodiment 3

[0041] Dissolve polystyrene-ethylene-butylene-styrene (SEBS) with a molecular weight of Mn≈65000 and a styrene block content of 30wt.% in organic reagent chloroform, stir mechanically, protect the temperature with nitrogen, and raise the temperature to 55°C, then add SnCl 4 and BCMB, where SEBS with chloroform, BCMB and SnCl 4 The mass volume ratios are 1g:30mL, 1g:4.6mL and 1g:2.0mL respectively, react for 12h, pour the reacted solution into anhydrous methanol, after the polymer is precipitated, suction filter, wash with deionized water to medium properties, and then dried in a vacuum oven at 60°C to obtain chloromethylated polystyrene-ethylene-butylene-styrene (CMSEBS)

[0042] Preparation of cross-linked ordered AAEM: Chloromethylated polystyrene-polyethylene-polybutylene triblock polymer and N,N,N,N-tetramethylhexamethylenediamine were selected as anion exchange The resin precursor and the functionalization reagent are respectively dissolved in chloroform and deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com