Preparation method of negative electrode slurry and method for solving gel problem of negative electrode slurry

A negative electrode slurry, slurry technology, applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of negative electrode slurry gel, slurry gel, etc., and achieve the effect of solving the problem of slurry gel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The preparation method of negative electrode slurry of the present invention comprises the following steps:

[0025] (1) under stirring, sodium carboxymethyl cellulose and deionized water are mixed, then defoaming and standing to obtain sodium carboxymethyl cellulose glue;

[0026] (2) Under stirring, add active material, conductive agent, a part of sodium carboxymethyl cellulose glue and styrene-butadiene latex successively in the mixing container, then add deionized water to adjust the viscosity to obtain a slurry, the slurry The mass ratio of the active substance, sodium carboxymethyl cellulose, styrene-butadiene latex and conductive agent is (95-96): (1.65-1.75): (1.9-2.1): 1;

[0027] (3) under stirring, add another part of the sodium carboxymethyl cellulose glue to the slurry prepared in step (2), so that the quality of the active material, sodium carboxymethyl cellulose, styrene-butadiene latex and conductive agent The ratio is (95-96):(1.95-2.05):(1.9-2.1):1. ...

Embodiment 1

[0038] (1) Sodium carboxymethyl cellulose and deionized water were mixed, then defoamed and left to stand for 24 hours to obtain a sodium carboxymethyl cellulose glue with a solid content of 2% by weight.

[0039] (2) under stirring, add graphite, conductive carbon black Super P, a part of sodium carboxymethylcellulose glue and styrene-butadiene latex successively in the mixing container, then add deionized water to adjust the viscosity to obtain the slurry, the The mass ratio of graphite, sodium carboxymethyl cellulose, styrene-butadiene latex and conductive carbon black Super P in the slurry is 95.5:1.7:2:1.

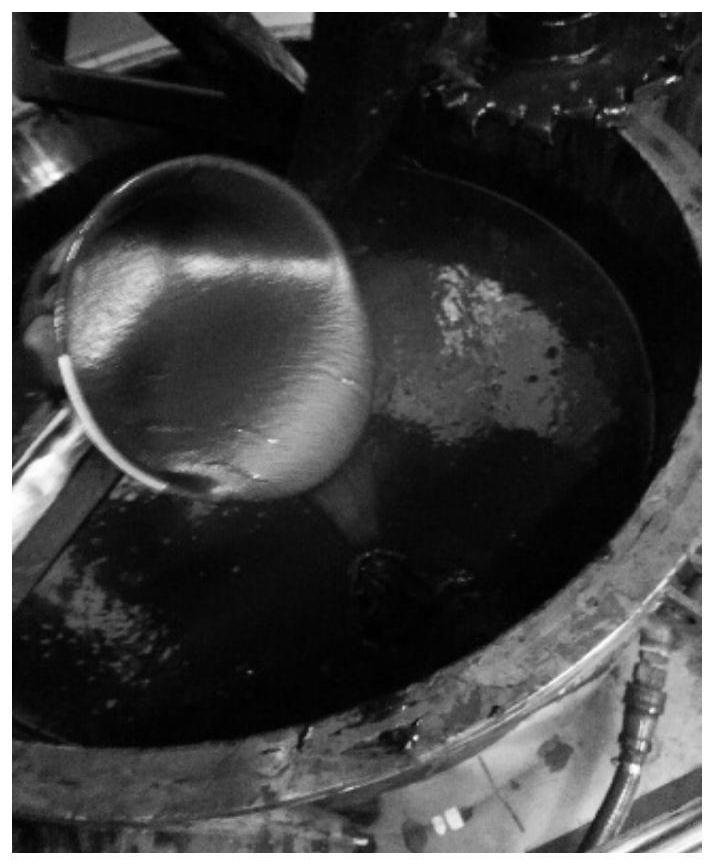

[0040] (3) under stirring, add another part of sodium carboxymethyl cellulose glue to the slurry prepared in step (2), so that graphite, sodium carboxymethyl cellulose, styrene-butadiene latex and conductive carbon black Super P The mass ratio of is 95.5:2:2:1, thereby preparing negative electrode slurry A1. The photo of the paste is as figure 1 As shown, the slurry ...

Embodiment 2

[0045] When the slurry prepared in Comparative Example 1 was a sesame paste gel, under stirring, sodium carboxymethylcellulose glue (solid content was 2% by weight) was added thereto, so that graphite, sodium carboxymethylcellulose The mass ratio of styrene-butadiene latex and conductive carbon black Super P is 95.5:2:2:1. After stirring for 15 minutes, the fluidity of the slurry recovers and can be sieved normally.

[0046] It can be seen that according to the method of the present invention, negative electrode slurry with better fluidity can be prepared, and the problem of slurry gel can be solved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com