Coating machine nozzle cleaning module and its device

A technology for cleaning devices and coating machines, applied in cleaning methods and utensils, photoplate-making process coating equipment, chemical instruments and methods, etc., can solve problems such as incomplete cleaning of nozzles, and achieve the effect of improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

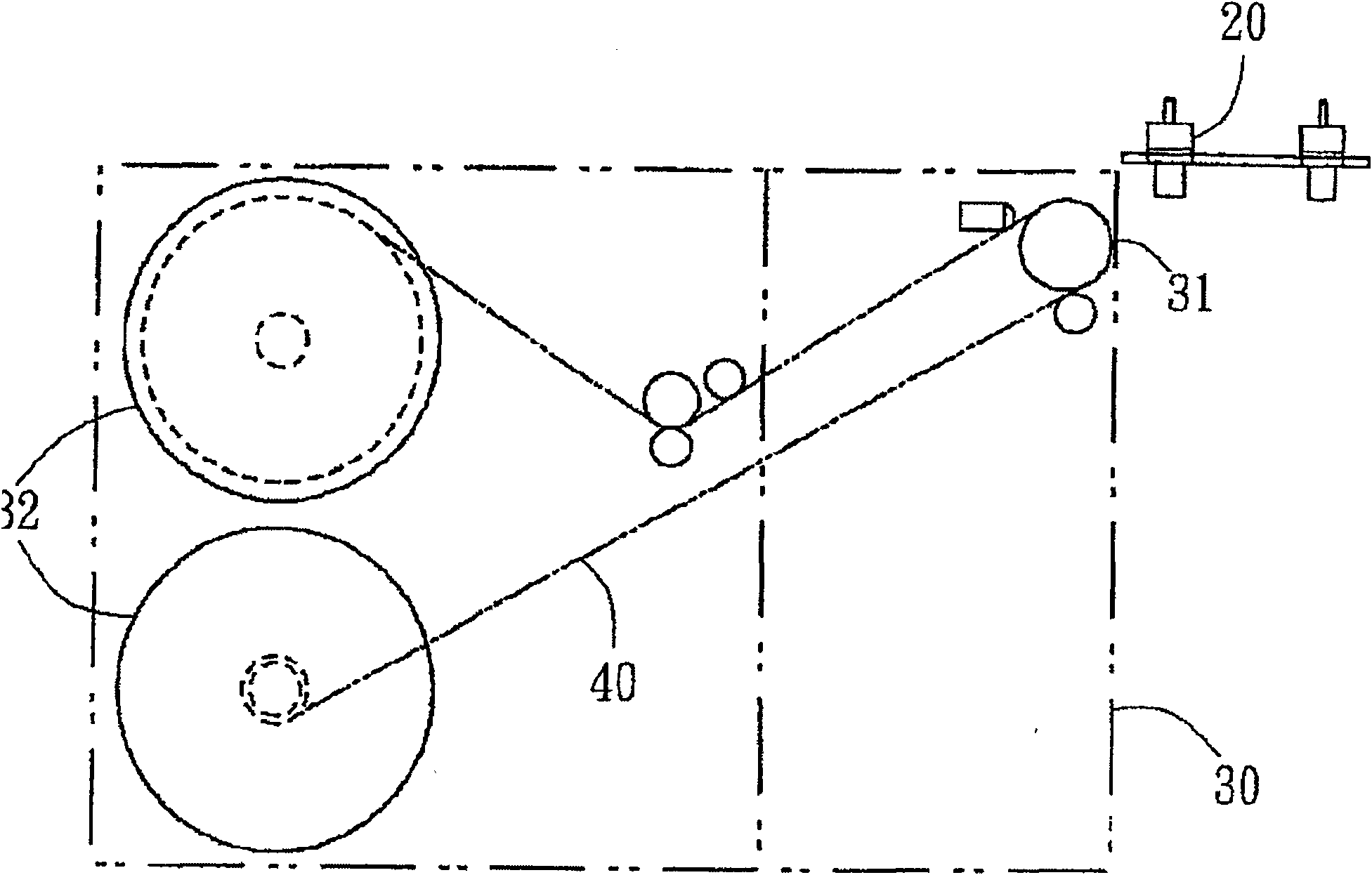

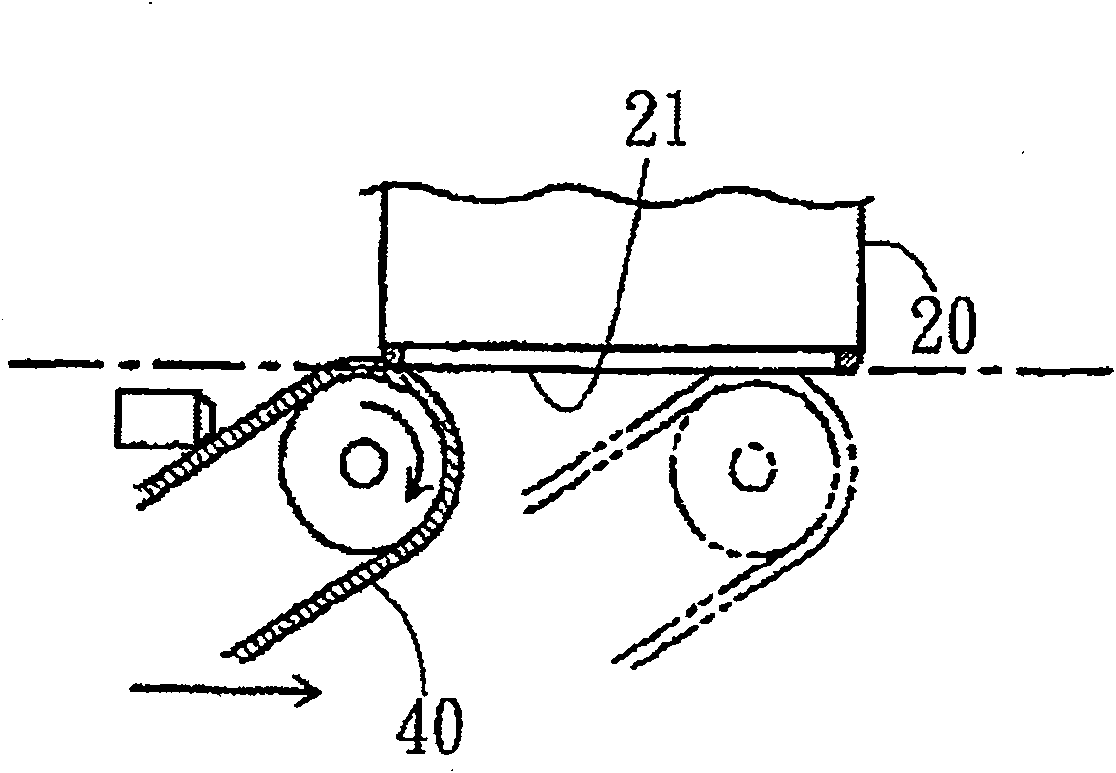

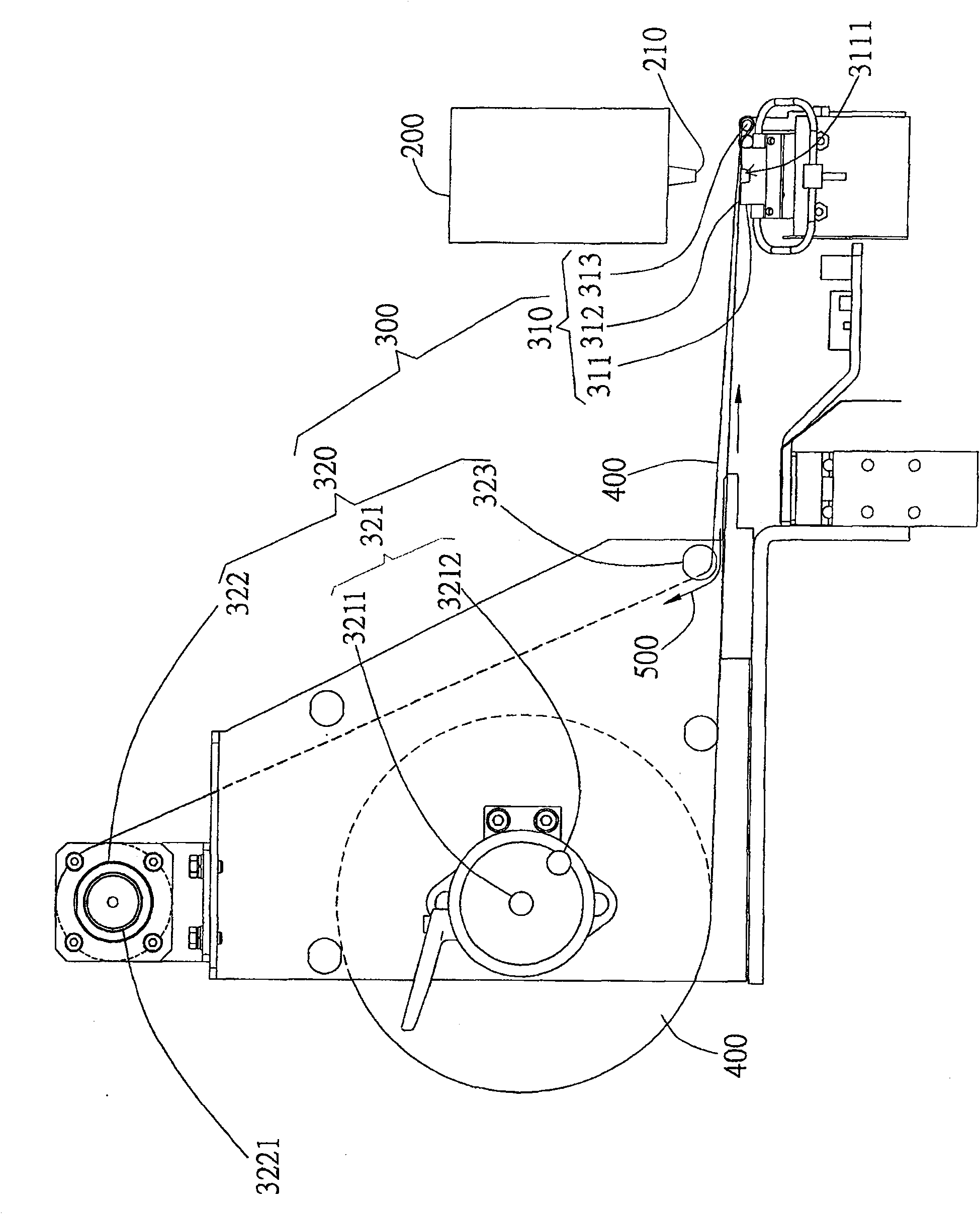

[0039] The invention provides a coating machine nozzle cleaning module and its device for thoroughly cleaning the coating machine nozzle to reduce the occurrence of problems and improve the production yield. The coating machine nozzle cleaning module and device thereof of the present invention can solve the gel problem generally existing in the coating machine, so as to improve the production yield. The coating machine nozzle cleaning module and its device of the present invention are preferably used in conjunction with cleaning materials with high elasticity, softness and adsorption. When the cleaning material is between the tip of the nozzle and the cleaning part, it will automatically conform to the nozzle due to elasticity. The shape of the tip absorbs the excess photoresist at the tip of the nozzle, which can strengthen the cleaning effect of the nozzle and reduce the probability of gel generation.

[0040] The cleaning material used in the nozzle cleaning module of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com