Preparation method of organic phase change composite material and prepared phase change composite material

A composite material and organic phase technology, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of overheating heat storage performance, system overcooling, low thermal conductivity, etc., to increase thermal conductivity and phase change latent heat High, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

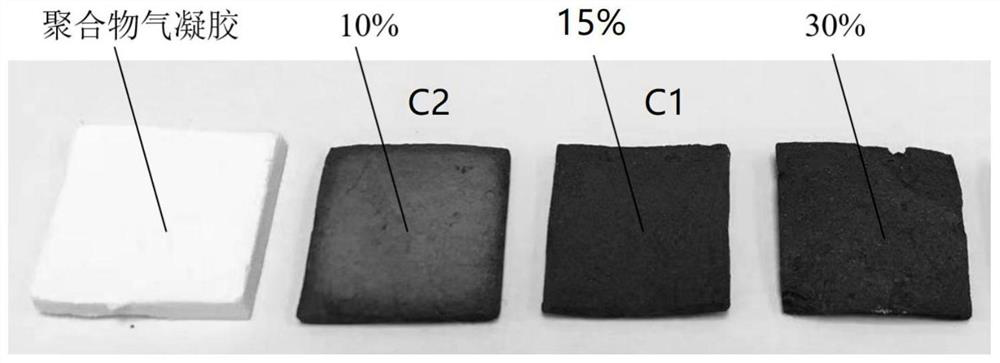

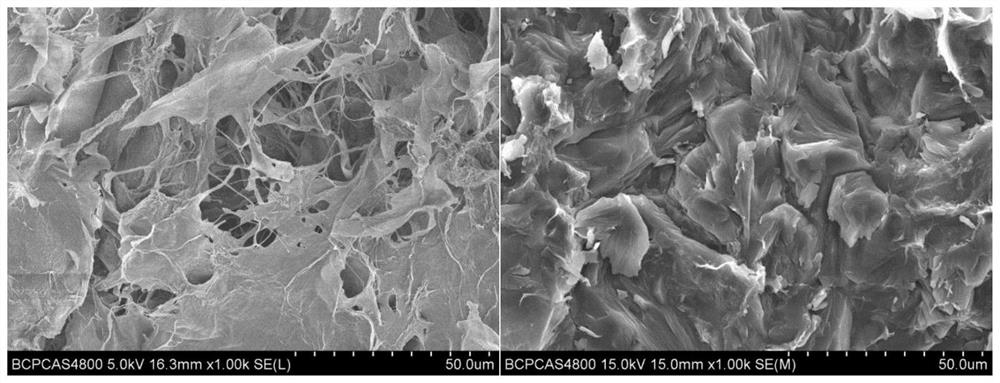

[0035] Immerse poly-p-phenylene terephthalamide airgel (porosity 94.7%) in sucrose solution (sucrose 15g, water 85g), vacuumize and place the system in an ultrasonic cleaner (200W) for 1.5 hours , take it out and freeze-dry it; then put the poly-p-phenylene terephthalamide airgel impregnated with sucrose into the quartz tube of the tube furnace, fill the system with argon gas, and the flow rate of argon gas is 10-20mL / min, so that there is no active gas such as oxygen in the quartz tube, the temperature of carbonization is 350 ° C, and the time is 3 hours to form a carbon-coated airgel material.

[0036] Using the method of vacuum impregnation, vacuum impregnate the above-mentioned carbon-coated airgel material in polyethylene glycol (average molecular weight 4000) melt (80 ° C), and take out the airgel impregnated with polyethylene glycol after 24 hours The material was placed in an oven at 100°C and heated to a constant weight to obtain a polymer airgel organic phase change...

Embodiment 2

[0044] This example is similar to Example 1, except that the concentration of the sucrose solution is changed to 10 g of sucrose and 90 g of water, the other conditions are the same, and a polymer airgel organic phase change composite material is obtained, which is marked as C2.

Embodiment 3

[0046] The poly-p-phenylene terephthalamide airgel (porosity 94.7%) was immersed in glucose solution (glucose 25g, water 75g), vacuumized and the system was placed in an ultrasonic cleaner (300W) for 1.5 hours , take it out and freeze-dry it; then put the poly-p-phenylene terephthalamide aerogel impregnated with glucose into the quartz tube of the tube furnace, fill the system with argon gas, and the flow rate of argon gas is 10-20mL / min, so that there is no active gas such as oxygen in the quartz tube, the temperature of carbonization is 350 °C, and the time is 4 hours to form a carbon-coated airgel material.

[0047] Using the method of vacuum impregnation, the above-mentioned carbon-coated airgel material is vacuum-impregnated in polyethylene glycol (average molecular weight 4000) melt (80 ° C), and the airgel impregnated with polyethylene glycol is taken out after 18 hours The material was placed in an oven at 100°C and heated to a constant weight to obtain a polymer airg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| encapsulation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com