High-thermal-conductivity silicone rubber cable material as well as preparation method and application thereof

A silicone rubber, high thermal conductivity technology, applied in rubber insulators, organic insulators, etc., can solve the problem of the thermal conductivity of cable materials needs to be improved, to improve flame retardant properties and mechanical properties, improve thermal conductivity, and reduce cable damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

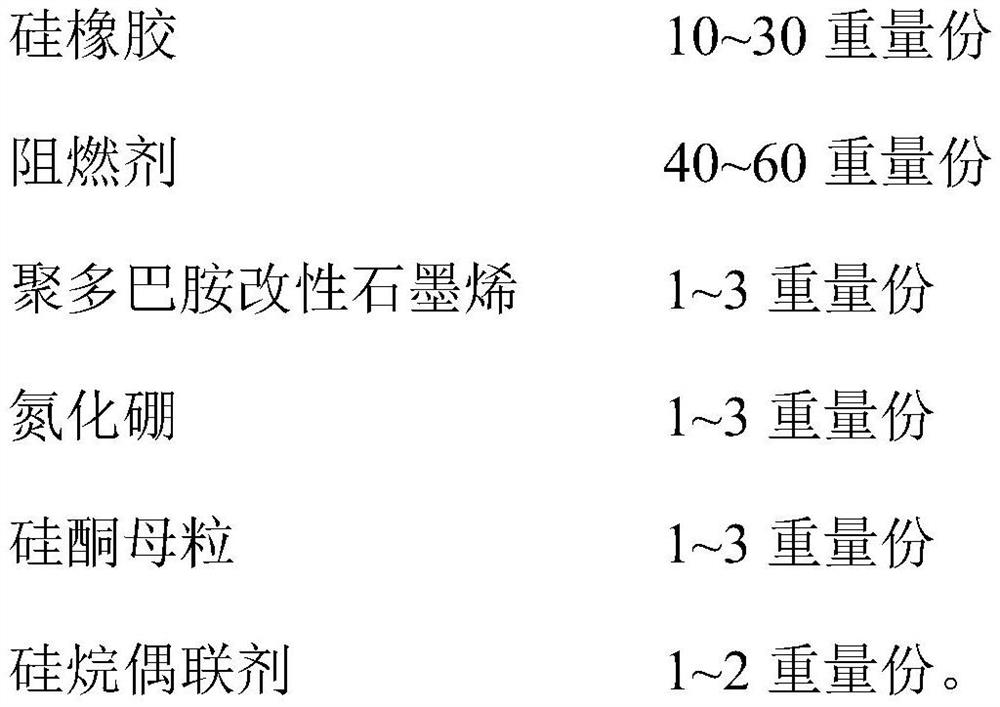

[0053] A high thermal conductivity silicone rubber cable material, which comprises the following components in parts by weight:

[0054]

[0055] Its preparation method comprises the following steps:

[0056] (1) Methyl vinyl silicone rubber, magnesium hydroxide, aluminum hydroxide, polydopamine modified graphene (mix dopamine and graphene with a mass ratio of 1:1 in deionized water at 50°C for 2h to obtain the described Polydopamine-modified graphene), boron nitride, compatibilizer, stabilizer, silicone masterbatch, silane coupling agent and antioxidant were mixed at 160°C for 25 minutes, and then passed through a single-screw extruder to form granules. The single-screw extruder includes the first zone, the second zone, the third zone, the fourth zone, the fifth zone, the sixth zone and the seventh zone connected in sequence, and the materials pass through each zone in turn, and the working temperature of the first zone is set to 110℃, the working temperature of the secon...

Embodiment 2

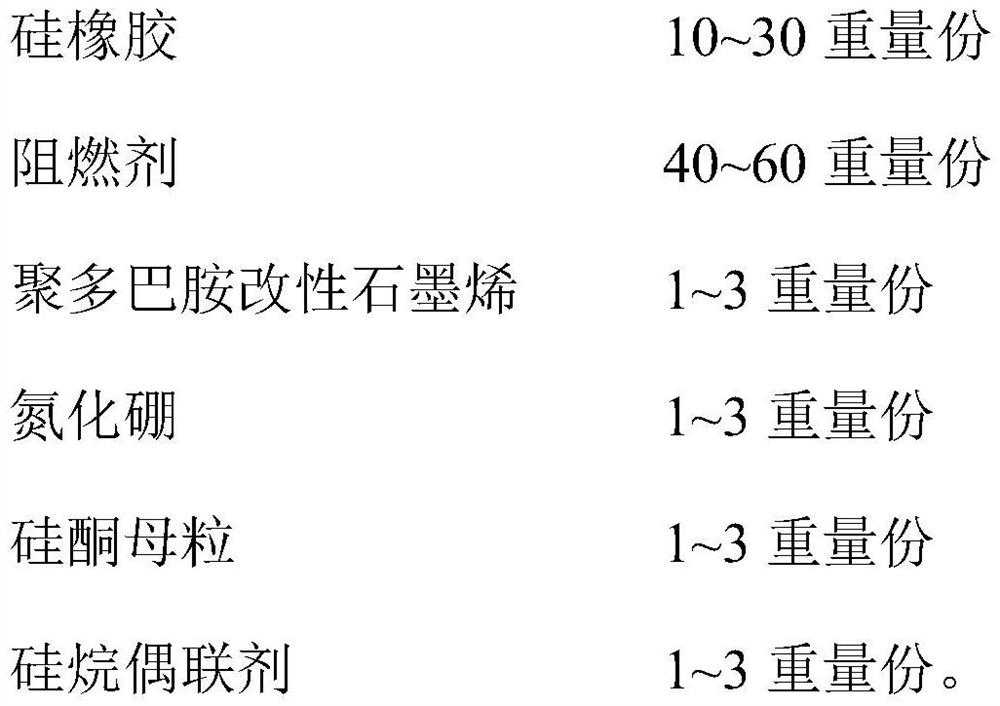

[0059] A high thermal conductivity silicone rubber cable material, which comprises the following components in parts by weight:

[0060]

[0061]

[0062] The preparation method of the high thermal conductivity silicone rubber cable material provided in this embodiment is the same as that of the high thermal conductivity silicone rubber cable material provided in Example 1.

Embodiment 3

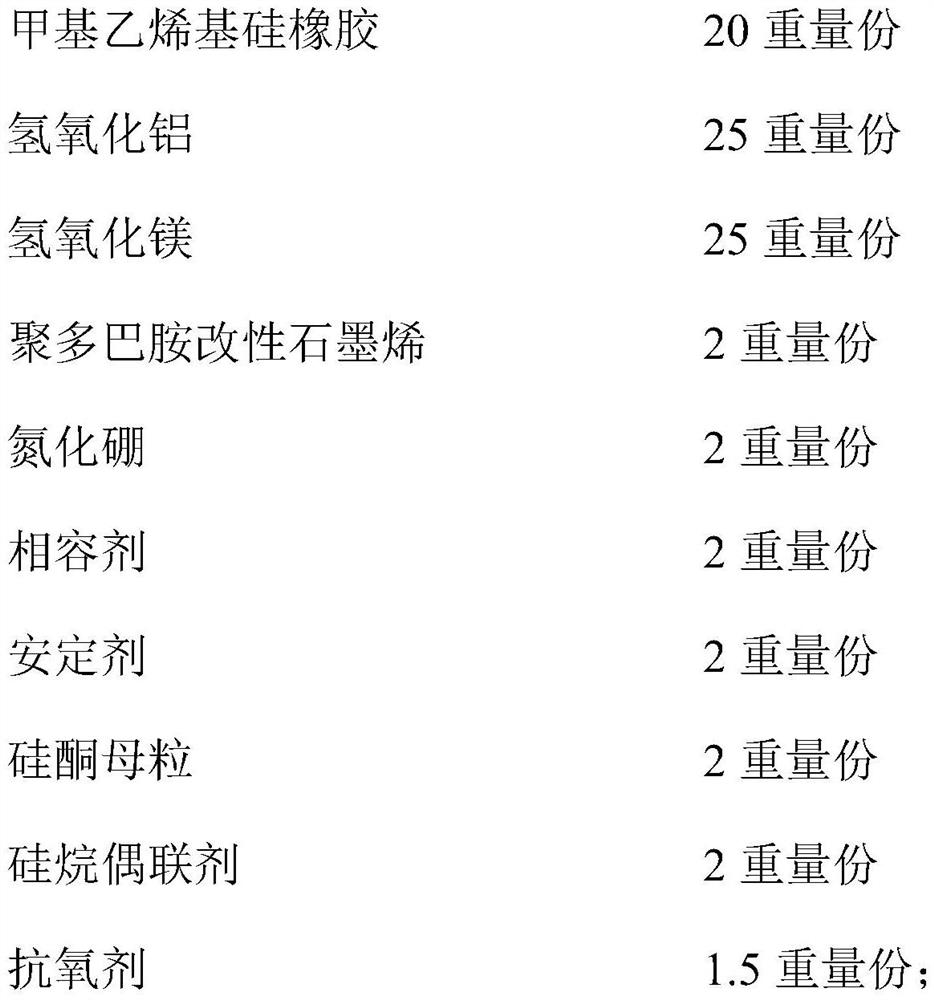

[0064] A high thermal conductivity silicone rubber cable material, which comprises the following components in parts by weight:

[0065]

[0066] The preparation method of the high thermal conductivity silicone rubber cable material provided in this embodiment is the same as that of the high thermal conductivity silicone rubber cable material provided in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com