High-strength aluminum alloy seamless tube extrusion process method and device

A process method, aluminum alloy technology, applied in the direction of metal extrusion, metal extrusion control equipment, metal processing equipment, etc., can solve the problems of easy scratches, low yield of extruded seamless pipes, and extrusion temperature affecting the surface of pipes Quality and production efficiency and other issues, to achieve the effect of convenient direct processing and avoid material overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

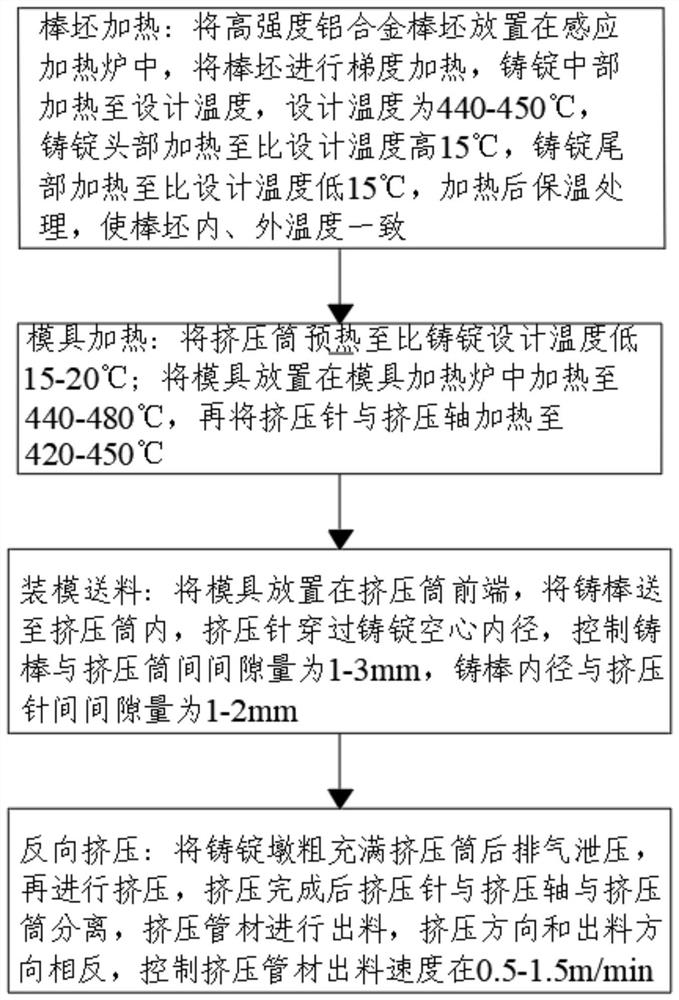

[0047] Such as figure 1 As shown, a high-strength aluminum alloy seamless pipe extrusion process, the specific steps are as follows:

[0048] Step 1. Billet heating: place the high-strength aluminum alloy billet in the induction heating furnace, heat the billet gradiently, heat the middle part of the ingot to the design temperature, the design temperature is 440 ° C, and heat the head of the ingot to the design temperature The temperature is 15°C higher, and the tail of the ingot is heated to 15°C lower than the design temperature. After heating, heat preservation treatment is carried out to make the temperature of the inside and outside of the billet consistent;

[0049] Step 2. Mold heating: Preheat the extrusion barrel of the extruder to 20°C lower than the design temperature of the ingot; place the mold in a mold heating furnace and heat it to 440°C, and then heat the extrusion needle and extrusion shaft to 420°C;

[0050] Step 3, mold loading and feeding: place the mold...

Embodiment 2

[0054] Such as figure 1 As shown, a high-strength aluminum alloy seamless pipe extrusion process, the specific steps are as follows:

[0055] Step 1. Billet heating: place the high-strength aluminum alloy billet in the induction heating furnace, heat the billet gradiently, heat the middle part of the ingot to the design temperature, the design temperature is 450 ° C, and heat the head of the ingot to the design temperature The temperature is 15°C higher, and the tail of the ingot is heated to 15°C lower than the design temperature. After heating, heat preservation treatment is carried out to make the temperature of the inside and outside of the billet consistent;

[0056] Step 2. Mold heating: Preheat the extrusion barrel of the extruder to 150°C lower than the design temperature of the ingot; place the mold in a mold heating furnace and heat it to 480°C, and then heat the extrusion needle and extrusion shaft to 450°C;

[0057] Step 3, mold loading and feeding: place the mol...

Embodiment 3

[0062] Embodiment 3 is a further improvement to Embodiment 1.

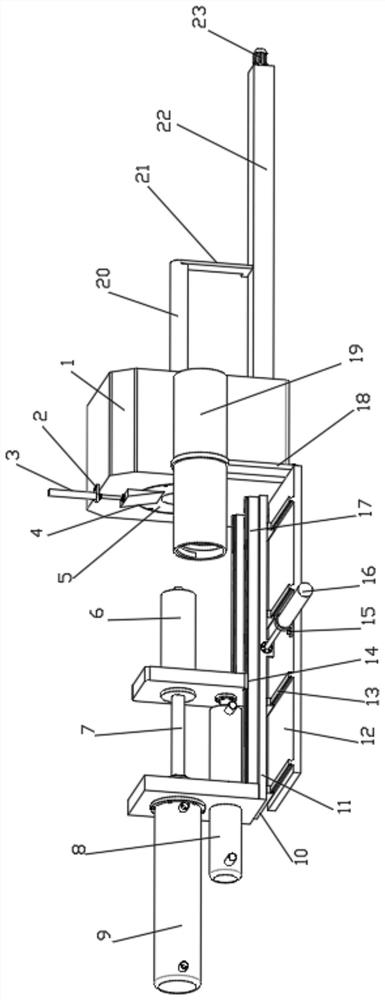

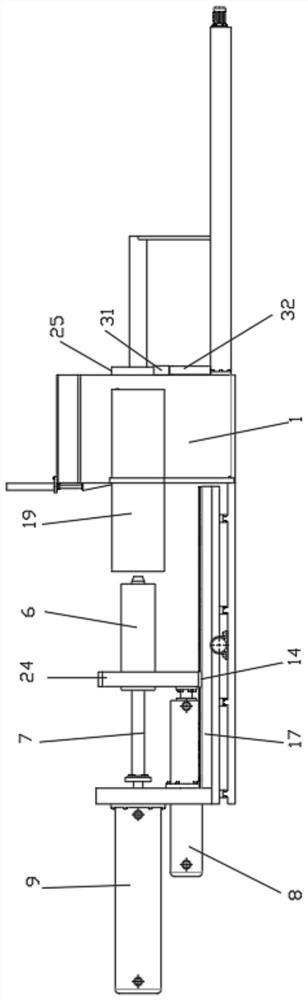

[0063] Such as figure 2 , 3 , 4, 5, 6, 7, 8, 9, 10 and 11, a device for a high-strength aluminum alloy seamless pipe extrusion process, the device is a pressing machine in step 1, including an extrusion seat 1, A second horizontal groove 29 is opened in the extrusion seat 1, and a second spiral electromagnetic heater 30 for heating is installed in the second horizontal groove 29, and an extrusion cylinder 5 is fixedly installed in the extrusion seat 1 in the second horizontal groove 29. , the inner wall of the second spiral electromagnetic heater 30 is in contact with the outer wall of the second transverse groove 29, the ingot is placed in the extrusion cylinder 5, and the heated extrusion cylinder 5 is beneficial to keep the ingot at the set temperature;

[0064] The extrusion seat 1 is fixed with a straight plate 32 on the side wall of the extrusion end of the extrusion barrel 5, and the top of the straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com